How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

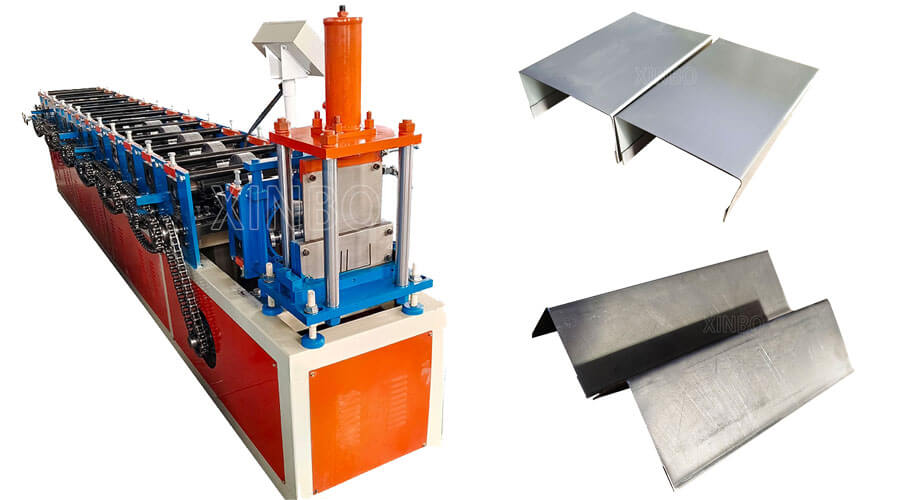

Versatile U L Channel Roll Forming Machine

U L channel roll forming machine is specialized equipment that transforms flat metal sheets into U and L-shaped channels through a continuous bending process. The machine employs a series of rollers that gradually shape the metal, allowing for consistent dimensions and high-quality finishes. The versatility of this machine enables manufacturers to produce channels of different sizes, thicknesses, and materials, catering to diverse application needs.

Key Features

Technical Specifications

| Processing Material | PPGI/ GI coils |

| Input Width | customized |

| Formed Width | As drawings/needing |

| Processing Thickness | Standard: 0.6mm/customized |

| Frame Style | square pipe welded |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 40mm |

| Production Speed | Standard: 0–15m/min; customized |

| Roller Driven | Decelerating Motor+China Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 4+4KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Company Certificates