How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

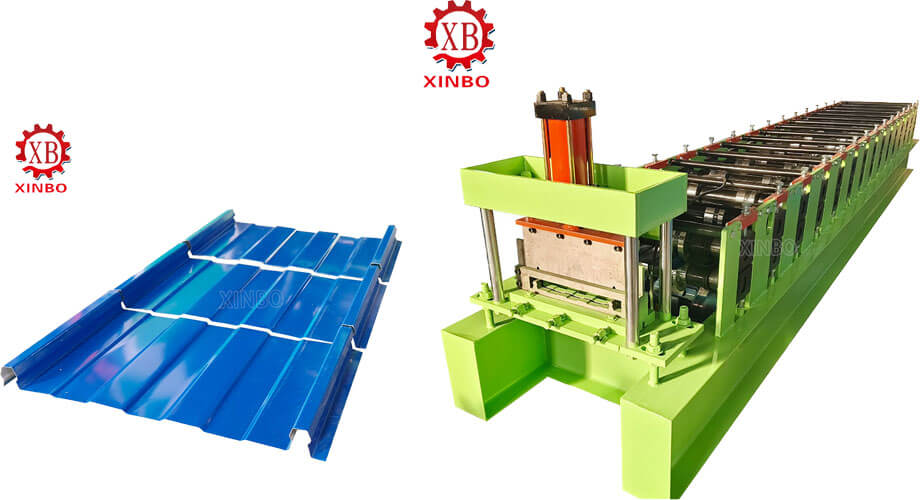

Standing Beam Roof Panel Machine

The standing beam roof panel machine is an invaluable asset for any manufacturing facility involved in roof panel production. Its efficiency, precision, and versatility make it a top choice for builders and contractors looking to enhance their construction processes.

The standing beam roof panel machine are widely used in:

– **Residential Construction**: Producing panels for homes that require efficient and durable roofing solutions.

– **Commercial Buildings**: Manufacturing panels that meet the specific needs of commercial structures, providing both functionality and aesthetic appeal.

– **Industrial Facilities**: Creating robust roof panels that can withstand harsh environments and heavy loads.

Technical Specifications of this roll forming machine

| Processing Material | PPGI/GI/Aluminium coils |

| Input Width | customized |

| Formed Width | as needing |

| Processing Thickness | Standard: 0.3—0.7mm |

| Frame Style | 350mm H beam welded |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 70mm |

| Production Speed | Standard: 0–15m/min; customized |

| Roller Driven | Chain Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 3+3KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Company Certificates