How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

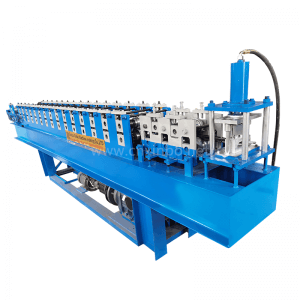

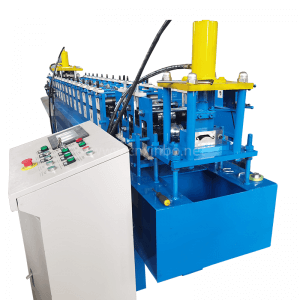

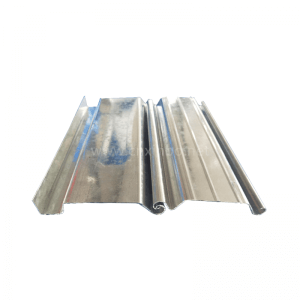

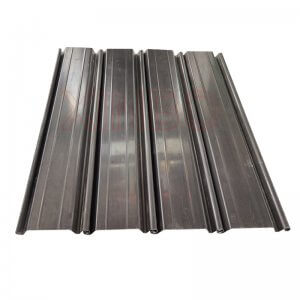

Shutter door roll forming machine

A shutter door roll forming machine is a highly efficient and automated machine used in the manufacturing process of shutter doors. This machine is designed to produce high-quality and precise profiles that are used in the construction industry.

The roll forming process involves feeding a metal strip into the machine, which then passes through a series of rollers. These rollers gradually shape the metal strip into the desired profile. The machine is equipped with different sets of rollers, each designed to create a specific part of the shutter door profile. This ensures that the final product is uniform and meets the required specifications.

|

Main Parameter of Roll Forming Machine |

|

|

Processing Material |

PPGI,GI |

|

Input Width |

as customer needing |

|

Formed Width |

as customer needing |

|

Processing Thickness(mm) |

0.4–1.0mm |

|

Material of Rollers |

45# steel, with hard chrome coated |

|

Production Speed |

0-20m/min |

|

Roller Driven |

Decelerating Motor + Chain Transmission |

|

Cutting Model |

Hydraulic mould Cutting |

|

Length Measurement |

Encoder |

|

Control Style |

PLC |

|

Operation Model |

Button+touchscreen |

|

Total Power |

3+3KW |

|

Voltage |

380V 50HZ 3Phase or at buyer’s request |