How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

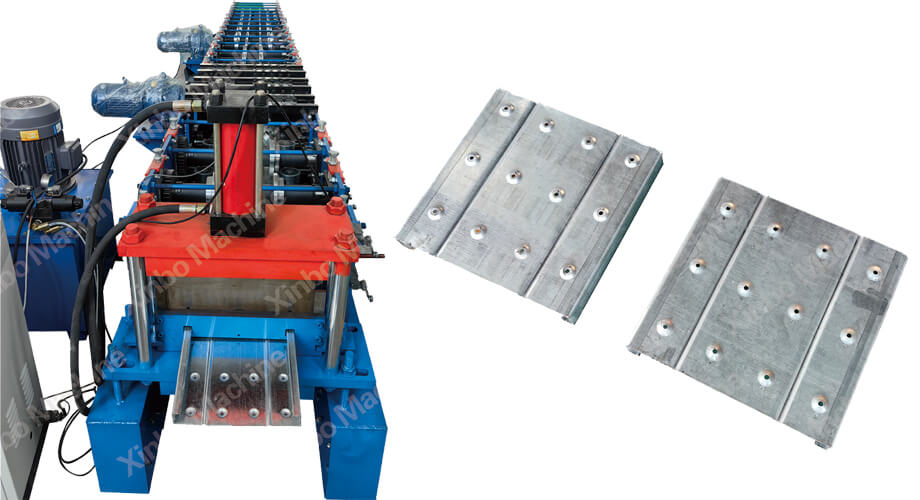

Scaffold Plate Roll Forming Machine

Scaffold plate roll forming machine is a specialized piece of equipment designed to produce scaffold plates through a continuous and automated process. The machine takes flat metal sheets, typically made of steel or aluminum, and shapes them into the desired profile using a series of rollers. This process not only enhances the structural integrity of the plates but also improves their aesthetic appeal.

Technical Specifications of this scaffolding plate roll forming machine

| Processing Material | GI coils |

| Input Width | customized |

| Formed Width | As drawings/needing |

| Processing Thickness | Standard: max 1.5mm/customized |

| Frame Style | 350mm H steel welded |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 80mm |

| Production Speed | Standard: 0–15m/min(without punching); customized |

| Roller Driven | Decelerating Motor+China Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 5.5+4KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Company Certificates