Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

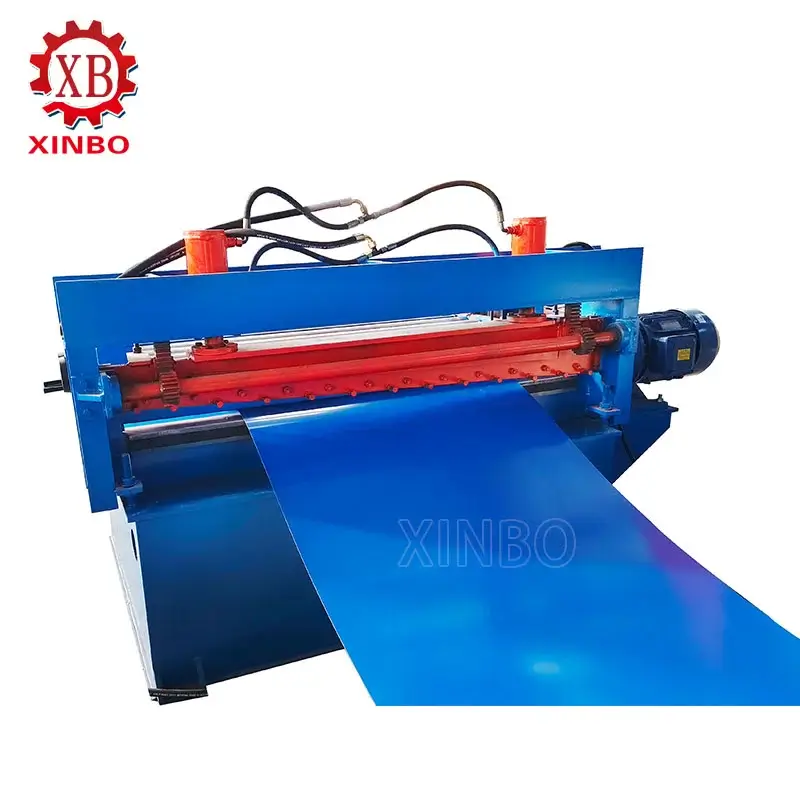

VIEW MORE→The Steel Coils Slitting Line is one of the important technologies in manufacturing, as it allows efficiently transforming large steel coils into narrow, precision-cut strips. The process plays a critical role in various industries, from automotive and construction to appliances and packaging. This article aims to discuss the technical aspects of slitting lines, focusing on the most innovative features and market advantages. Besides, it points out the standout features of the Steel Coils Slitting Line from XinBo Machine, a brand trusted by manufacturers around the world.

A Steel Coils Slitting Line refers to an advanced production system that splits wide metal coils into variable-width strips to meet specified widths of particular projects. These are supposed to deliver perfect accuracy of the materials and reduce wastage while achieving high efficiency in operations. Equipped with automation integrated high-precision rotary blades, Slitting lines fulfill the demands for diversities in modern manufacturing industries.

Top-quality slitting lines are designed with special components for smooth operation. The important parts include:

The slitting process comprises four basic steps:

This process emphasizes speed, precision, and minimal material waste, making it indispensable for industries that demand high accuracy.

With technological advancements, slitting lines have evolved into fully automated systems. Here are some innovations reshaping the industry:

Precision slitting is called for in the making of car body panels, frames, and structural components-all having to be produced to tight dimensional and strength tolerances.

The slit steel is in wide demand from the construction industry for the making of pipes, beams, and roofing panels. Consistent quality maintains the structural integrity in all kinds of projects.

Thinner strips of steel are manufactured and used in appliances such as refrigerators, washing machines, and air conditioners. The slitting process assures tight tolerances for improved performance and longevity.

Metal packaging products, such as cans and lids, require high-quality, slit steel for uniformity and durability.

In wind turbines and solar panel supports, slit steel ensures precision and strength, supporting the growing demand for clean energy solutions.

As one of the leading manufacturers of slitting lines, XinBo Machine provides the latest technology with features to meet global demands. Following are the technical specifications for their Steel Coils Slitting Line:

– Processing Material: PPGI, GI, aluminum, zinc coils/sheets.

-Input Width: 914mm/925mm/1000mm/1200mm/1220mm/1250mm (customizable).

– Slitting Width: Adjustable for various applications.

– Thickness Range: Standard maximum of 2.0mm, with handwheel adjustments.

– Production Speed: 0–15m/min (customizable for faster outputs).

– Control System: Fully automatic with computer integration for precision.

– Frame Style: Sturdy 400mm H steel beam welding.

– Power Requirements: 3KW standard, with tailored options.

– Voltage: 380V, 50Hz, 3-phase (customizable to buyer needs).

XinBo provides flexible machine designs, accommodating unique client requirements, including size, capacity, and material processing needs.

In-house manufacturing processes keep costs manageable, making high-quality equipment accessible.

From CNC machining to quality checks, XinBo ensures timely delivery through streamlined operations.

Each machine undergoes three rounds of inspections, guaranteeing performance and reliability.

XinBo’s reputation extends across Europe, North America, and Asia, serving a diverse client base with innovative technology.

The future of slitting lines is bright, with emerging trends focusing on:

The Steel Coils Slitting Line has become an indispensable part of the industries that demand precision, efficiency, and adaptability. With XinBo Machine, you work with a reliable manufacturer that guarantees state-of-the-art solutions at very competitive prices. With a focus on quality, customization, and innovation, they make sure your line is always working at top capacity.

For inquiries or to request a quote, contact XinBo Machine today:

Invest in XinBo’s Steel Coils Slitting Line and transform your manufacturing processes with unparalleled precision and efficiency.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→