What Makes Coil Material Cutting Machines Essential for Production?

Why Are Coil Material Cutting Machines Crucial in Modern Manufacturing?

In the world of manufacturing today, coil material cutting machines are tools that help streamline production processes by ensuring precise and consistent cutting of materials to specific lengths. Industries are constantly seeking ways to improve efficiency and minimize waste making these machines more vital to their operations.

The Role of Coil Material Cutting Machines in Enhancing Efficiency

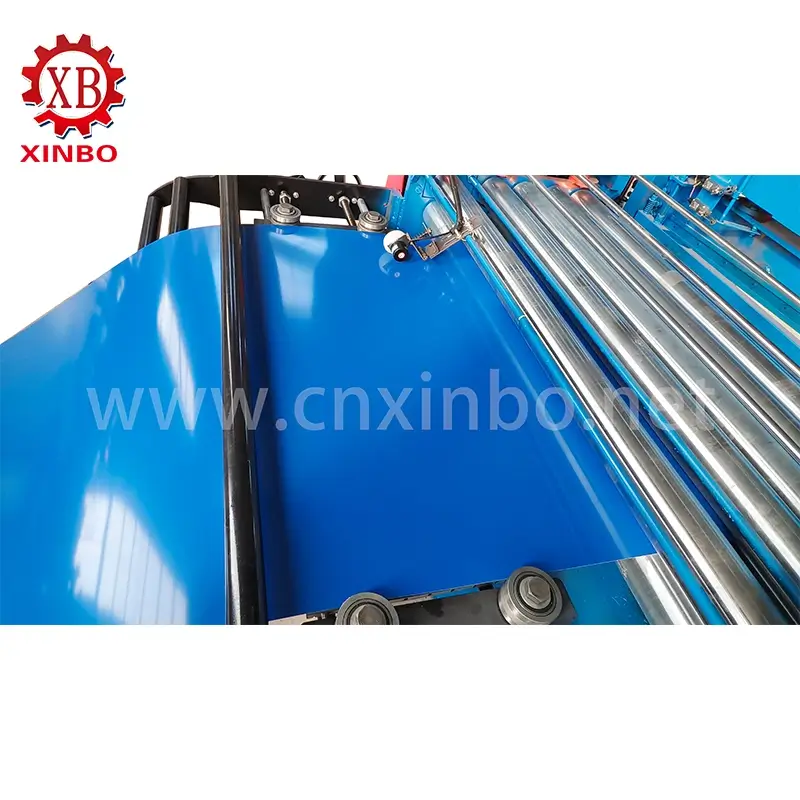

Cutting machines for coil material are created to manage amounts of material with human involvement needed efficiently handling the cutting process leads to less time and labor required resulting in improved production efficiency they guarantee precise cuts to minimize waste and make the most of resources used.

How Do Cutting-to-Length Machines Improve Product Quality?

Machines that trim materials to size play a role in enhancing product quality by delivering cuts that match specific requirements precisely. This accuracy guarantees that the end products seamlessly integrate into their designated uses without requiring tweaks or alterations. Maintaining uniform product dimensions enhances customer contentment. Diminishes the chances of mistakes, during assembly or installation procedures.

What Are the Key Features of Advanced Coil Material Cutting Machines?

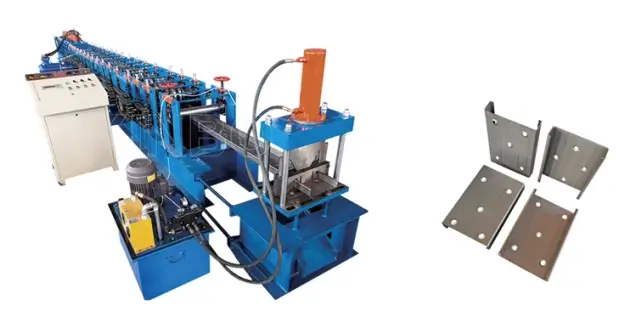

Cutting-edge coil material cutting machines today come with a range of capabilities to meet industrial requirements effectively enhancing performance and providing operational flexibility in the process.

Technological Advancements in Coil Material Cutting Machines

Cutting-edge technology has revolutionized coil material cutting machines into tools, with automated control systems and precision sensors for operation and enhanced accuracy. These advancements in technology help manufacturers uphold quality standards and adjust to evolving production requirements.

Customization Options Available for Different Industries

Various sectors have demands that can be addressed with the help of cutting-edge coil material cutting machines that come with customization features tailored to meet those requirements. Adjusting the cut thickness and configuring machine parameters for materials are among the options available in these advanced machines to ensure that every industry can maximize the returns on their equipment investments.

How Do Coil Material Cutting Machines Contribute to Cost-effectiveness?

Manufacturers often prioritize cost effectiveness to boost profitability without compromising quality with coil material-cutting machines playing a role in achieving this balance through cost-saving advantages.

Minimizing Downtime and Maintenance Costs

One key benefit of utilizing coil material cutting machines is their capacity to reduce downtime by operating and needing maintenance work. The machines are built with designs and dependable parts that necessitate repairs, resulting in lower maintenance expenses, in the long run. This dependability leads to production timelines and fewer disruptions.

Energy Efficiency and Environmental Considerations

Coil material-cutting machines are cost-effective, due to their focus on energy efficiency as a factor. Their design ensures they use power while still achieving output levels resulting in lower energy expenses. In addition to that the machine’s efficient performance also aids in reducing carbon footprints. This aligns well with the emphasis placed by industries towards environmental sustainability goals.

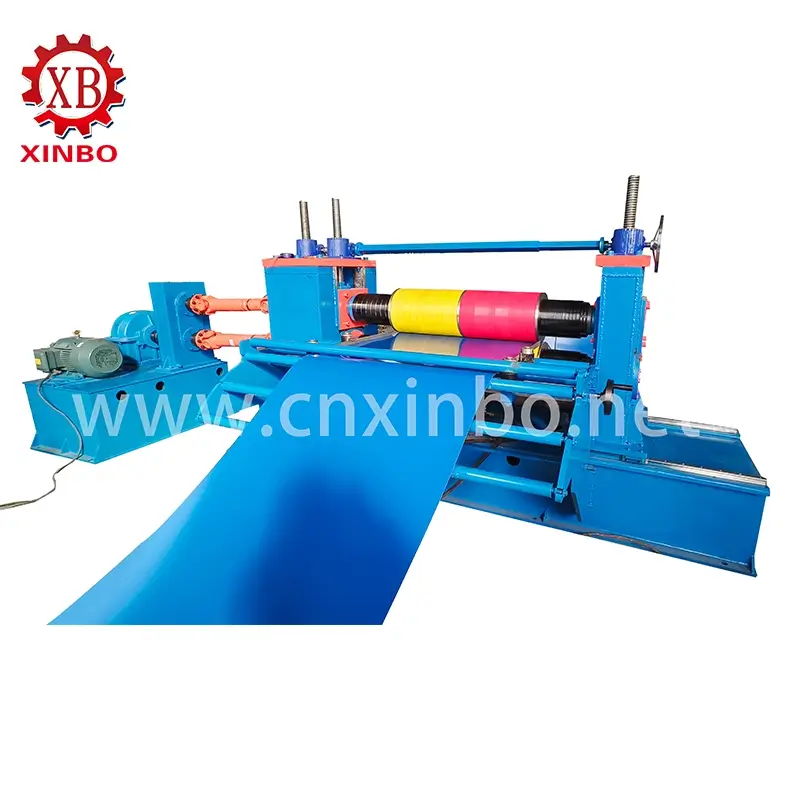

If you’re, in search of high-quality manufacturing solutions customized to your requirements XinBo Machine Making Co. Ltd provides a selection of machinery such as roll-forming machines specifically crafted for uses like producing purloins or floor decking panels. Established in 2014, XinBo values its cutting-edge technology and commitment, to quality ensured by a team of experts who guarantee that each machine meets customer needs effectively.

By acquiring state-of-the-art coil material cutting equipment, from trusted suppliers such as XinBo Machine Making Co., Ltd. you can upgrade your manufacturing capabilities drive cost efficiencies, and contribute to a production environment—firmly establishing them as an asset, in today’s industrial settings.

Where Can You Find Reliable Coil Material Cutting Machines?

It’s essential to find a supplier for coil-cutting machines to maintain the quality and durability of your production operations. The ideal supplier doesn’t just deliver top-notch equipment. Also provides assistance and customization choices tailored to your requirements.

Introducing XINBO MACHINE MAKING CO. LTD.

When looking for coil material cutting machines, XINBO MACHINE MAKING CO., LTD. emerges as a manufacturer. Founded in 2014 in China this company is known for its high-quality machinery. They offer a variety of roll-forming machines designed for purposes including the production of purlins and floor decking panels.

At XinBo Manufacturing Corp., their dedication, to excellence shines through in their quality control procedures, for every machine before it leaves the factory floor; going through three stages of inspection guarantees that each part adheres to standards of accuracy and dependability consistently upheld by the company reputation.” Furthermore ” XinBo also provides customization options so you can adjust machinery specifications to suit your production needs perfectly.”

Evaluating Suppliers for Quality Assurance

When assessing suppliers such, as XinBo Machine Making Co., Ltd. it’s important to take into account aspects like their industry reputation and customer feedback along with the quality of purchase assistance they offer. A trustworthy supplier is expected to provide in-depth training and technical aid to assist in the integration of equipment, into your current operations.

Make sure to verify whether the provider has a quality control system established with consistent checks, in place and compliance, with industry norms while using reliable parts that guarantee lasting efficiency.

How Can You Optimize Your Production with Coil Material Cutting Machines?

Enhancing production efficiency with coil material cutting machines requires integrating them into your operations and consistently enhancing their effectiveness by utilizing feedback and analyzing data.

Best Practices for Integrating New Machinery into Existing Systems

For results, from your coil material cutting equipment, it’s important to adhere to recommended procedures when integrating them into your operations. Begin by evaluating your production system to pinpoint any obstacles or opportunities, for enhancement. Work closely with your vendor to verify that the new machines work well with your tools and procedures.

It’s crucial to ensure that your employees are well trained especially when it comes to using the machinery in an effective manner as this will not just boost productivity but also reduce the chances of mistakes that could cause delays or harm.

Continuous Improvement Through Feedback and Data Analysis

After incorporating the changes into the system’s operation routine and consistently collecting feedback from employees while regularly reviewing performance data; you can quickly pinpoint any inefficiencies or bottlenecks in the production process.

Utilizing data-driven approaches can result in improvements, in machine efficiency, with the passage of time. Precisely leverage data analysis findings to make informed choices regarding maintenance timetables tweaking processes and even upgrades as needed.

Following these methods and guidelines, in place of using these strategies and techniques mentioned above can aid in ensuring that your coil material cutting equipment runs efficiently at its level while adjusting to changing production requirements—leading to long-term growth and competitiveness, within your sector.

Acquiring state-of-the-art coil material-cutting equipment, from trusted vendors such as XinBo Machine Making Co. Ltd doesn’t just streamline your production procedures; it also supports cost efficiency and eco-friendly practices making them essential tools, in today’s environments.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia