What is the Roll Forming Technique? Discover its Secret Advantages

Introduction

Definition and Overview

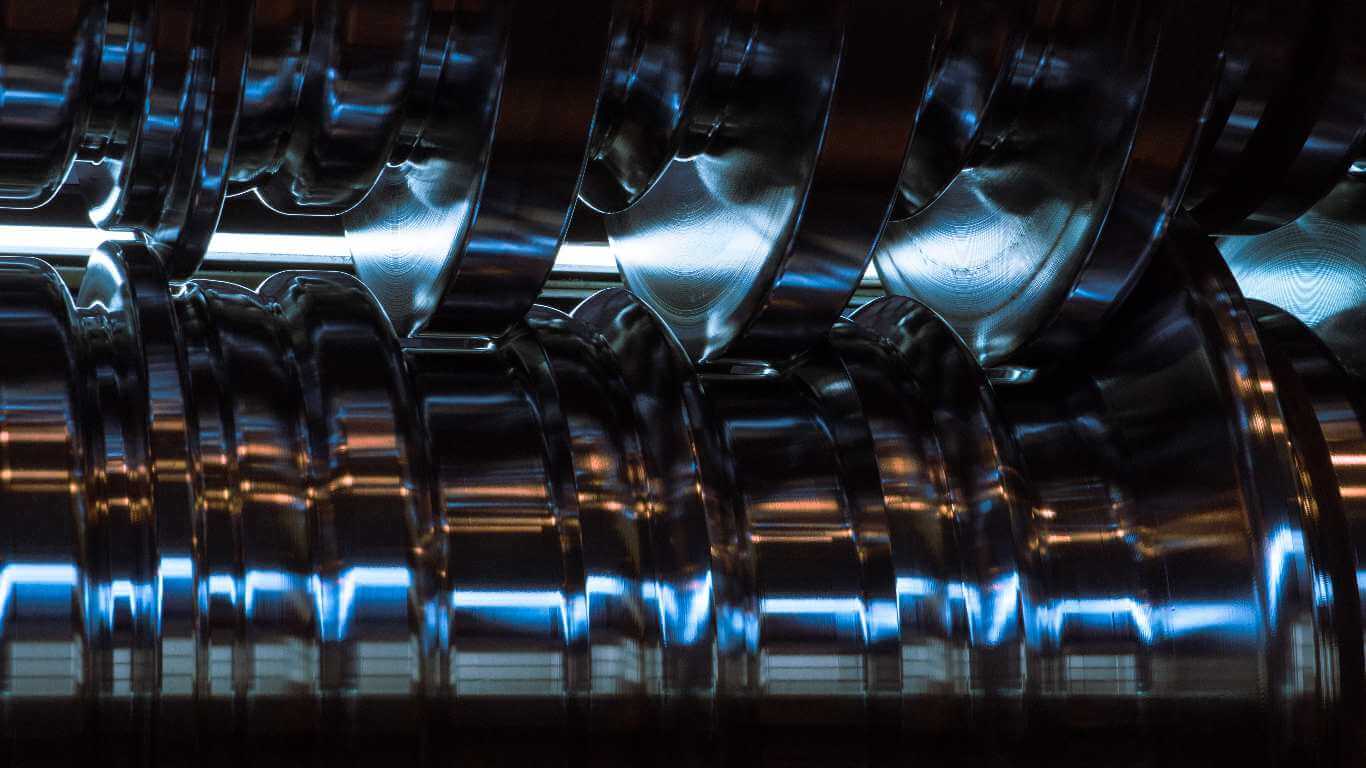

Roll forming is a continuous bending operation in which a long strip of sheet metal, typically coiled steel, is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend, until the desired cross-section profile is obtained. The roll forming technique is celebrated for its ability to produce complex profiles with exceptional accuracy and repeatability, making it an indispensable process in metal fabrication. Unlike press braking, which requires manual manipulation for each bend, roll forming offers a more automated and efficient solution.

History and Evolution

The roll forming technique has seen significant evolution since its inception. It traces its roots back to the late 19th century when the demand for metal sections in various industries began to rise. Initially, the machines were rudimentary, offering limited capabilities. However, with advancements in technology and material science, roll forming has become highly sophisticated. During the mid-20th century, the integration of computer numerical control (CNC) systems revolutionized the technique, allowing for greater precision and automation. Today, roll forming is a staple in industries ranging from automotive to construction, continually evolving with innovations like machine learning and real-time monitoring.

How Roll Forming Works

Essential Components of Roll Forming Machines

To understand how the roll forming technique works, it’s crucial to know the essential components of roll forming machines:

Stands and Rolls

The stands and rolls are the backbone of any roll forming machine. The stands are robust structures that support the rolls, which are engineered to exact specifications to shape the metal as it passes through. Each roll is crafted to perform a specific bend or form, contributing to the gradual shaping of the metal. The correct alignment and calibration of these stands and rolls are pivotal for maintaining the precision of the roll forming process.

Cut-off Mechanisms

Once the metal has been shaped into its final form, it must be cut to the desired length. This is where cut-off mechanisms come into play. These mechanisms must be highly accurate to ensure that each piece meets the required dimensions. Typically, they include flying cut-off methods that allow for continuous processing without stopping the machine, thereby enhancing productivity.

Entry Guides

Entry guides are essential for directing the raw material into the roll forming machine. By ensuring that the metal strip enters the machine correctly, entry guides help prevent misfeeds and material waste. They play a significant role in maintaining the quality and consistency of the final product.

Basic Principles of the Process

The roll forming technique operates on the fundamental principle of incremental bending. As the metal strip progresses through the machine, each set of rolls performs a small part of the bend. This gradual approach reduces the likelihood of material stress and deformation, allowing for the production of profiles with tight tolerances and complex geometries. Moreover, the process is highly repeatable, making it ideal for high-volume production runs.

Key Benefits of Roll Forming

Efficiency and Cost-Effectiveness

One of the most compelling benefits of the roll forming technique is its efficiency and cost-effectiveness. Because the process is continuous, it can produce long lengths of complex profiles without interruption. This reduces labor costs and enhances productivity. Furthermore, the use of pre-cut metal coils minimizes material waste, offering additional cost savings.

Material Versatility

The roll forming technique is compatible with a wide range of materials, from common metals like steel and aluminum to more specialized alloys. This versatility allows manufacturers to select the best material for their specific application, balancing factors such as strength, weight, and corrosion resistance. As a result, roll forming can meet diverse industrial needs.

Precision and Consistency

Precision and consistency are hallmarks of the roll forming technique. The use of computer-controlled systems ensures that each part is produced to exact specifications, reducing the need for secondary operations or adjustments. This high level of precision is particularly valuable in industries where components must meet stringent standards, such as automotive or aerospace.

Applications of Roll Forming in Different Industries

Automotive Industry

The roll forming technique is indispensable in the automotive industry, where it is used to manufacture a myriad of components including body panels, bumpers, and structural frameworks. The ability to produce parts with high precision ensures that modern vehicles meet both safety standards and aesthetic requirements. Additionally, the roll forming technique allows for the use of lightweight, high-strength materials, which contribute to fuel efficiency and overall vehicle performance. This is particularly crucial as the industry moves towards more sustainable and environmentally friendly solutions.

Construction Sector

In the construction sector, roll forming is widely used to produce building materials such as steel studs, roof panels, and gutter systems. The technique offers several advantages, including the ability to create long, continuous pieces that minimize joints and potential leak points. This is particularly beneficial for roofing and cladding applications where durability and weather resistance are paramount. Moreover, the precision offered by roll forming ensures that components fit together seamlessly, speeding up construction timelines and reducing labor costs.

Consumer Goods Manufacturing

Roll forming also plays a critical role in the consumer goods sector. It is employed to produce items ranging from household appliances to office furniture. The technique’s ability to create complex profiles with high repeatability ensures that consumer products are both functional and aesthetically pleasing. Furthermore, the versatility in material selection allows manufacturers to choose metals that meet specific performance criteria, such as corrosion resistance for kitchen appliances or lightweight materials for ease of handling. The cost-effectiveness of roll forming also helps keep consumer prices competitive.

Tips for Optimizing Roll Forming Processes

Material Selection Criteria

Thickness

Selecting the appropriate material thickness is crucial for optimizing the roll forming process. The chosen thickness must balance strength and flexibility to ensure the metal can be shaped without cracking or deforming. Engineers often use computer simulations to determine the ideal thickness for specific applications, thereby reducing trial and error and enhancing efficiency.

Strength

The strength of the material is another critical criterion. High-strength materials like advanced high-strength steels (AHSS) are increasingly popular in industries such as automotive and aerospace. However, these materials can be challenging to form, requiring specialized tooling and machine settings. Proper material selection ensures that the final product meets performance requirements without causing excessive wear on the roll forming equipment.

Surface Finish

The surface finish of the material can significantly impact the roll forming process. A smooth finish reduces friction between the metal and the rolls, decreasing the likelihood of surface defects. On the other hand, materials with textured surfaces may require additional processing steps to achieve the desired finish. Manufacturers often apply lubricants to improve surface finish and prolong the life of the tooling.

Maintenance of Equipment

Regular maintenance of roll forming equipment is essential for optimal performance and longevity. This includes routine inspections to identify and address wear and tear on rolls and stands, calibration of equipment to maintain precision, and lubrication of moving parts to reduce friction and prevent overheating. Implementing a proactive maintenance schedule can minimize downtime, ensure consistent product quality, and extend the lifespan of the machinery. Additionally, advancements in predictive maintenance technologies, such as IoT sensors and machine learning algorithms, allow for real-time monitoring and predictive analytics, further enhancing efficiency and reliability.

By following these guidelines, manufacturers can maximize the benefits of the roll forming technique, ensuring high efficiency, cost-effectiveness, and product quality.

XINBO is a well-known manufacturer of Roll Forming Machine.

XINBO‘s Roll Forming Machine is a cutting-edge piece of equipment designed for the manufacturing industry. XINBO, a Chinese manufacturer established in 2014, is the proud creator of this machine. The company prides itself on providing top-notch quality assurance through a team of professional designers, producers, and workers.

The Roll Forming Machine incorporates new and innovative technology, catering to the specific requirements of customers in Europe, the UK, and Canada. It is designed to efficiently roll form metal sheets into various shapes and sizes, meeting the diverse needs of different industries. XINBO also offers standard class options for normal consumption.

This machine is highly adjustable, allowing for easy customization according to specific requirements. It can handle cold rolling and special designing as per customer needs. Additionally, the Roll Forming Machine can be conveniently loaded into a standard 40ft HQ container, resulting in significant logistic savings for international clients.

XINBO’s Roll Forming Machine is backed by a team of professional engineers and designers who can provide detailed drawings based on customer requirements in a short time. The company has its own workshop and CNC machining machines, ensuring cost savings and efficient production processes.

To ensure the highest quality, each machine undergoes three inspections before shipping to customers. This meticulous approach guarantees that every part and profile of the machine meets the required standards.

In summary, XINBO’s Roll Forming Machine is a technologically advanced and versatile machinery designed for efficient and precise roll forming of metal sheets. It reflects XINBO’s commitment to innovation, customer satisfaction, and cost-effectiveness in the manufacturing industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia

-1.jpg)