What is a Roofing Machine?

With the continuous development of modern construction technology, metal roofing, as a new type of building material, is favored by more and more construction industries because of its advantages of beauty, durability and easy installation. And roofing machine is one of the important equipments to realize the production of metal roof. In this paper, we will introduce the definition, working principle, application areas and development trend of roofing machine in detail, in order to provide readers with a comprehensive understanding.

Definition of roofing machine

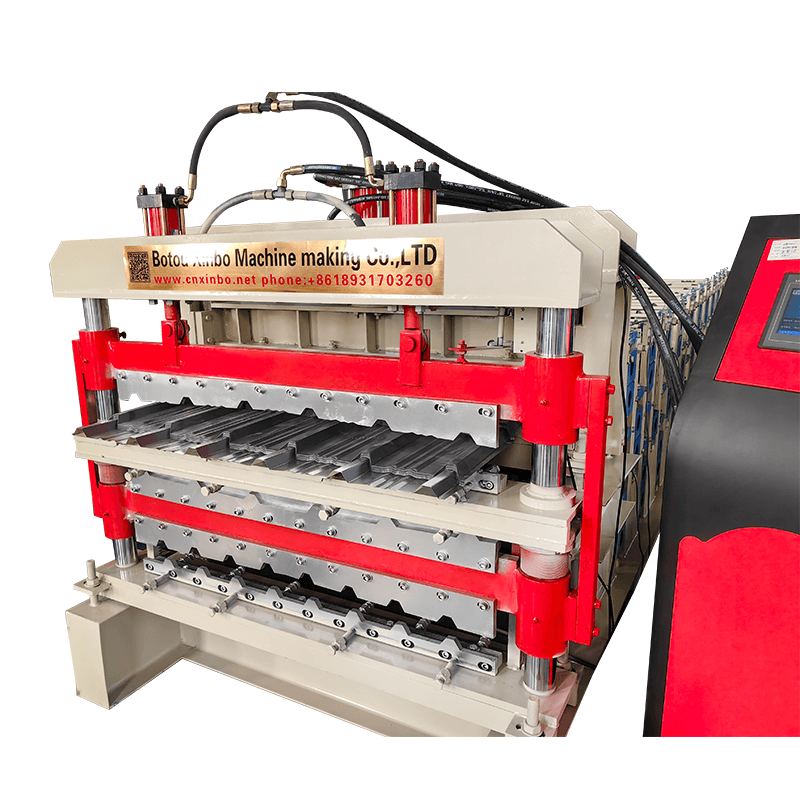

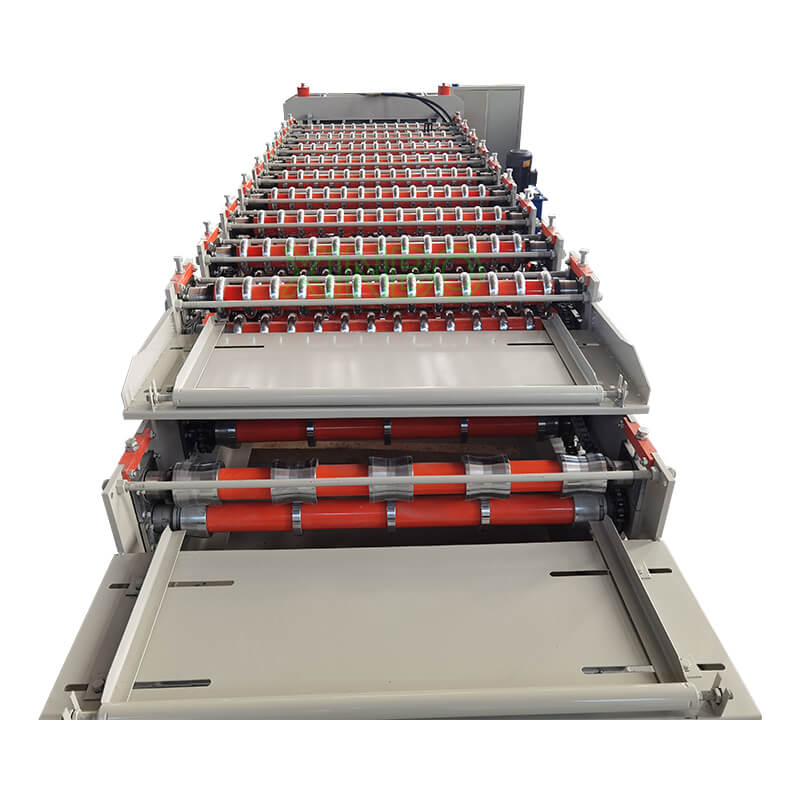

Roofing machine, also known as metal corrugated sheet molding machine or metal tile machine, is a kind of machinery and equipment specially used for making metal roofing materials of various shapes and specifications through continuous stamping, cutting, bending and other processes of metal coil or sheet. It usually consists of feeding mechanism, molding mechanism, cutting mechanism, hydraulic system and electrical control system, etc. It can realize automation and continuous production, which greatly improves the production efficiency.

Working principle of roofing machine

The working principle of roofing machine is mainly based on mechanical stamping and hydraulic transmission technology. The working process is as follows:

Discharge mechanism will be metal coil or sheet according to the set speed and direction into the molding mechanism.

The forming mechanism continuously presses and bends the metal sheet through a series of dies and rollers to form the desired waveform or shape.

During the forming process, the cutting mechanism cuts the metal sheet according to the set length to obtain a single metal roofing material.

Finally, it is precisely controlled by the hydraulic system and electrical control system to ensure the stability and accuracy of the whole production process.

Application field of roofing machine

Roofing machine is widely used in construction, transportation, metallurgy, chemical industry and other fields, especially in the construction industry. The following are some main application fields:

Construction industry: roofing machine can be used to make various metal roofing sheets, such as wave plate, trapezoidal plate, curved plate, etc. It is used to cover roofs and walls of industrial plants, warehouses, gymnasiums, exhibition halls and other buildings.

Transportation industry: In the construction of highways, railroads, bridges and other transportation facilities, roofing machine can be used to make protective barriers, sound insulation panels and other components to improve the safety and comfort of transportation facilities.

Metallurgical industry: In the manufacturing process of metallurgical equipment, roofing machine can be used to make protective cover, pipeline and other parts of the equipment to improve the service life and safety of the equipment.

Chemical industry: In the manufacture of chemical equipment and the construction of chemical plants, metal roofing machines can be used to make corrosion-resistant and high-temperature-resistant metal sheets to meet the needs of the chemical industry for special materials.

Advantages and characteristics of roofing machine

As a professional production equipment, roofing machine has the following advantages and features:

High efficiency: roofing machine adopts automatic and continuous production method, which greatly improves the production efficiency and shortens the production cycle.

Accuracy: Through precise mold design and hydraulic control system, the roofing machine is able to produce high-precision and high-quality metal roofing materials.

Versatility: The roofing machine can change the molds and adjust the parameters according to different demands to produce metal roofing materials of various shapes and specifications to meet diversified market demands

Environmental protection: metal roofing material has the characteristics of recyclable and reusable, which is in line with the green building concept and conducive to sustainable development.

Development trend of roofing machine

With the continuous progress of science and technology and the rapid development of the construction industry, the roofing machine is also constantly updated, showing the following development trends:

Intelligent: the future of the roofing machine will pay more attention to the application of intelligent technology, such as the introduction of artificial intelligence, Internet of Things and other technologies to achieve the remote monitoring of the equipment, fault diagnosis and automatic maintenance and other functions, to improve the level of intelligence of the equipment.

Modular: modular design will become an important development direction of the roofing machine, through the modular design, it can be convenient to replace and upgrade the equipment components, improve the flexibility and maintainability of the equipment.

Green: with the growing awareness of environmental protection, roofing machine will pay more attention to the enhancement of environmental performance, such as the use of low-energy, low-emission drive system and production process, to reduce the impact on the environment.

Personalized customization: With the diversification of market demand, the roofing machine will pay more attention to personalized customization services, according to customer demand for customized equipment and process solutions to improve market competitiveness.

Conclusion

As an indispensable and important equipment in the modern construction industry, the application and development of roofing machine is of great significance in promoting the technological progress and industrial upgrading of the construction industry. In the future, with the progress of science and technology and the changing needs of the market, the roofing machine will continue to innovate and improve, providing more efficient, environmentally friendly and personalized solutions for the development of the construction industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia