Unveiling the Marvel: Sheet Metal Roll Forming Machines Demystified

Exploring the Basics of Sheet Metal Roll Forming Machines

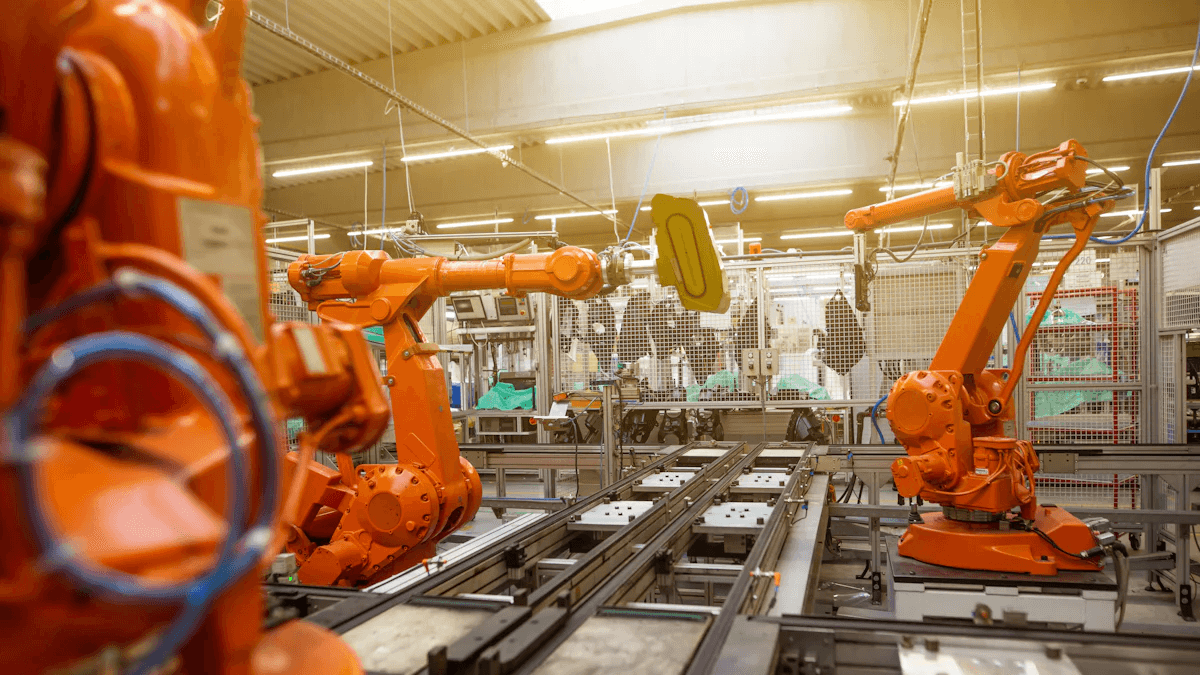

Sheet metal roll forming machines play a pivotal role in modern manufacturing, offering a cost-effective and efficient method for shaping sheet metal into various profiles and designs. These machines are witnessing significant market growth, with the global market size expected to reach USD 646.5 million by 2030, driven by their widespread use in industries such as automotive, construction, aviation, and oil & gas.

Roll Forming Machines Market Growth: The roll forming machines market size is estimated to grow at a CAGR of 4.27% between 2023 and 2028. The market size is forecast to increase by USD 178.37 million. The growth of the market depends on several factors such as the growing demand for CNC incorporated roll forming machines, increasing demand for automotive industry, and the increasing construction of residential and commercial buildings.

What Are Sheet Metal Roll Forming Machines?

Definition and Overview

Sheet metal roll forming machines are specialized equipment designed to transform flat sheets of metal into complex shapes and profiles through a continuous bending operation. This process involves passing sheet metal through a series of rollers, each adding shape to the material. The advantages of roll forming include high production efficiency, precise shaping, minimal material waste, and the ability to create complex profiles.

The Role in Modern Manufacturing

These machines have become indispensable in modern manufacturing due to their ability to reduce manual labor and increase productivity. Their technological advancements are fueling market expansion as they offer more efficient production processes compared to traditional metal shaping methods.

Key Components of Sheet Metal Roll Forming Machines

Rollers: The Shaping Wizards

Rollers are the core components of sheet metal roll forming machines. They exert precise pressure on the sheet metal as it passes through them, gradually shaping it into the desired profile. This process ensures consistent shaping and tight tolerances across the entire length of the material.

Material Handling Equipment: The Unsung Heroes

Material handling equipment plays a crucial role in front of and at the end of a roll forming line. It enhances production efficiency by facilitating smooth material feeding and handling at various stages of the roll forming process.

The Heart of the Process: How Sheet Metal Roll Forming Machines Work

Sheet metal roll forming machines are a marvel of modern engineering, utilizing advanced technology and precise control to transform flat sheets of metal into complex shapes and profiles. Understanding the step-by-step process and the precision involved in achieving tight tolerances is essential to demystifying the inner workings of these machines.

The Step-by-Step Process

Feeding the Beast: How Materials are Introduced

The process begins with feeding a flat sheet of metal through a successive series of hardened steel rollers, each station gradually shaping the material into a finished form as it passes through them. This method allows for rapid shaping of sheet metal into various shapes, from simple corrugations to completely closed long shapes. The gradual shaping prevents excessive stress on any particular area, ensuring uniformity across the entire length of the material.

The Transformation: From Flat Sheets to Complex Shapes

As the sheet metal passes through each set of rollers, it undergoes a transformation from its original flat state to intricate profiles and shapes. This gradual shaping process ensures that the material retains its structural integrity while achieving the desired design. The ability to create complex profiles with minimal material waste makes sheet metal roll forming machines an efficient and sustainable manufacturing solution.

Precision and Control: Achieving Tight Tolerances

The Role of Advanced Technology

Modern sheet metal roll forming machines leverage advanced technology to achieve precise shaping and tight tolerances. Automated servo-electric roll forming machines have revolutionized the industry by simplifying the metal forming process while ensuring a high degree of safety. Control units and sensor technology are employed for quality control and tool conversion, further enhancing precision and efficiency in production.

Operator Expertise and Equipment Maintenance

In addition to technological advancements, operator expertise plays a crucial role in maintaining tight tolerances during the roll forming process. Well-trained operators ensure that the machines are set up correctly and monitor production to guarantee consistent quality output. Furthermore, regular equipment maintenance is essential for preserving optimal performance and achieving tight tolerances over extended periods.

The utilization of cold forming in producing suspension and chassis parts enhances their strength and durability, making them better equipped to withstand rigorous conditions encountered during vehicle operation. Additionally, tube roll forming offers an efficient method for producing complex shapes with consistent metal thickness, providing cost-effective solutions with enhanced mechanical properties.

The Wide World of Applications

Sheet metal roll forming machines find diverse applications across various industries, showcasing their versatility and efficiency in meeting the complex shaping needs of modern manufacturing.

From Automotive to Construction: Diverse Uses

Crafting Automotive Panels and Parts

The automotive industry has long relied on sheet metal roll forming machines to craft a wide array of panels and parts essential for vehicle assembly. Cold forming, a key process enabled by roll forming technology, has significantly impacted the automotive sector. Case studies have demonstrated the success of cold forming in enhancing vehicle performance, efficiency, and safety. This method has proven to be a versatile and efficient solution for producing high-precision, customized components crucial for modern automotive design.

Building the Backbone of Structures

In the construction industry, sheet metal roll forming machines play a vital role in creating structural components that form the backbone of buildings and infrastructure. Roll forming systems have impressed customers for six decades with their ability to produce high-quality components essential for construction projects. Their impact extends beyond traditional building materials, as they also contribute to the development of innovative solutions for sustainable construction practices.

Beyond the Basics: Specialized Applications

The Art of Roll Embossing

Roll embossing is a specialized application that showcases the adaptability of sheet metal roll forming machines in creating intricate surface patterns on metal sheets. This technique has been particularly relevant in industries requiring aesthetically pleasing finishes or functional surface enhancements. Innovative systems for roll embossing have been introduced with the potential to cut manufacturing costs in half, making this process not only visually appealing but also economically advantageous.

Large and Thick Material Handling

The capabilities of sheet metal roll forming machines extend to handling large and thick materials, catering to industries with specific requirements for robust components. Cold roll forming machines have played a critical role in manufacturing car window rails, demonstrating their versatility in producing high-precision components tailored to meet stringent automotive standards. Additionally, these machines offer an efficient method for producing complex shapes with consistent metal thickness, providing cost-effective solutions with enhanced mechanical properties.

Xinbo Machine Making Co. Ltd, established in China since 2014, is a renowned manufacturer of sheet metal roll forming machines. These machines are designed with innovative technology to meet the needs of customers globally, particularly in Europe, the UK, and Canada.

Xinbo’s roll forming machines are highly efficient, easy to operate, and require minimal maintenance, making them a cost-effective solution for various industries. Each machine is inspected three times before shipping to ensure all parts and profiles meet the customers’ requirements. Xinbo also offers custom services, with a team of professional engineers and designers who can design detailed drawings as per customers’ needs in a short time.

The Future of Sheet Metal Roll Forming: Innovations and Advancements

As the manufacturing landscape continues to evolve, the future of sheet metal roll forming machines is poised for groundbreaking innovations and advancements. These developments are driven by the industry’s growing demand for efficient production processes, sustainable manufacturing solutions, and the ability to work with high-strength materials.

Cutting-Edge Technologies on the Horizon

Advanced Roll Forming Strategies for High-Strength Materials

In response to the increasing demand for high-strength materials in various industries, advanced roll forming strategies are being developed to accommodate these specialized requirements. Patents and technical documents have highlighted innovative approaches. These advancements include novel techniques for material handling, precise shaping methods, and enhanced control systems tailored to meet the challenges posed by high-strength alloys and composites.

Cost-Effective Manufacturing with Innovative Systems

The future of sheet metal roll forming machines also entails the integration of innovative systems designed to enhance cost-effectiveness in manufacturing processes. By incorporating these innovative systems, manufacturers can expect reduced waste, improved energy efficiency, and streamlined production workflows.

The Environmental and Economic Impact

Reducing Waste and Energy Consumption

Innovations in sheet metal roll forming technologies are driving significant strides towards reducing waste and energy consumption in manufacturing operations. These advancements align with global efforts towards sustainability by optimizing material usage during the roll forming process. Through optimized tooling designs, precision control systems, and advanced material handling techniques, manufacturers can minimize material waste while achieving higher levels of energy efficiency.

Making Manufacturing More Accessible

The future of sheet metal roll forming also encompasses initiatives aimed at making manufacturing more accessible across diverse industries. This includes developing user-friendly interfaces, automation features, and adaptable equipment configurations that cater to a wider range of applications. By enhancing accessibility, manufacturers can streamline their production capabilities while accommodating evolving market demands more effectively.

Wrapping Up: The Impact of Sheet Metal Roll Forming Machines

Revolutionizing Manufacturing, One Roll at a Time

Sheet metal roll forming machines have revolutionized the manufacturing landscape across various industries, offering efficient and sustainable solutions for shaping sheet metal into complex profiles and designs. Their impact extends beyond the production floor, influencing the quality and functionality of everyday products in automotive, construction, aerospace, and other sectors.

The Unseen Influence on Everyday Products

The influence of sheet metal roll forming machines is often unseen but deeply ingrained in the products we use daily. In the automotive industry, these machines play a pivotal role in manufacturing components such as bumpers, rocker panels, crash tubes, and door beams. Their ability to produce high-tensile-strength materials has significantly enhanced vehicle performance and safety. Furthermore, the construction sector relies on roll forming technology to create structural components that form the backbone of buildings and infrastructure. This demonstrates how these machines contribute to the durability and integrity of structures essential for modern living.

In addition to their foundational impact on traditional industries, sheet metal roll forming machines are also driving innovation in material development. For instance, advancements in aluminum sheet technology supported by roll forming have accelerated research and development initiatives in the automotive sector. This not only reflects their influence on current products but also hints at their role in shaping future materials for emerging technologies such as electrification.

Looking Ahead: The Continuous Evolution of Roll Forming

As technological advancements continue to unfold, the future of sheet metal roll forming machines appears promising. With an increasing focus on sustainable practices and material advancements, these machines are poised to address evolving market demands while overcoming challenges across diverse sectors. Embracing machine learning for process optimization and integrating intelligent manufacturing approaches will further enhance the capabilities of roll forming technology.

The rapid expansion of the automotive industry is expected to drive continued demand for roll forming machines as they become integral to producing lightweight yet robust components crucial for vehicle design. Moreover, addressing market demands through innovative systems designed to enhance cost-effectiveness will shape the continuous evolution of these machines.

In conclusion, sheet metal roll forming machines stand at the forefront of modern manufacturing innovation with their far-reaching impact on product quality, material development, and sustainability. By embracing technological advancements and overcoming challenges, this industry is well-positioned to play a vital role in shaping various sectors for years to come.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia