Unveiling the Facts What Metal Is Used for Roofing with Metal Roofing Machine

In recent times, metal roofing has become increasingly popular owing to its long-lasting nature, energy-saving properties, and visual attractiveness. But have you ever been curious about the specific metals typically utilized in metal roofing and managed by a metal roofing machine? Knowing the different metals used is essential to fully grasping the advantages that metal roofing offers.

Metals Commonly Used in Metal Roofing Machines

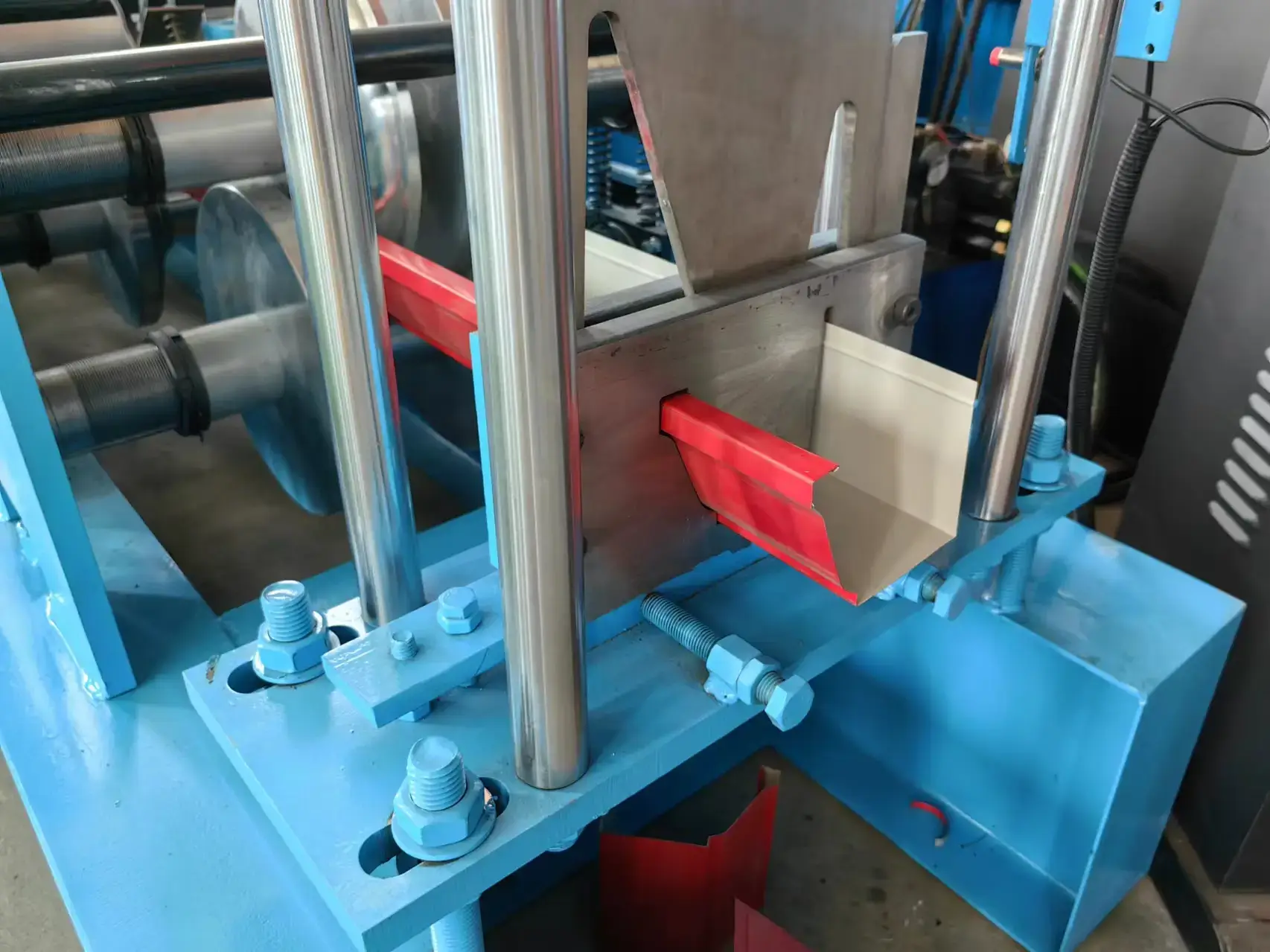

The metal roofing machine plays a crucial role in shaping and forming the various metal sheets used in roofing. Understanding the properties of metals commonly used in these machines helps in appreciating the results of the roofing systems.

XINBO offers ODM (Original Design Manufacturing) services, ensuring that their machines are designed and made according to customers’ requests. They have a team of professional engineers and technicians who can design detailed drawings based on customers’ needs in a short time. Additionally, XINBO‘s in-house workshop and CNC machining machines help save costs and ensure efficient production processes.

Steel and Its Varieties

Galvanized Steel Properties

Galvanized steel is typically manufactured with the help of a metal roofing machine. This material boasts strong resistance to corrosion and can withstand harsh environmental factors. The zinc layer serves as a shield against moisture and chemical interactions, which is crucial for preserving the roof’s durability.

Benefits of Using Galvanized Steel in Roofing

The benefits of using galvanized steel in roofing are numerous. Its affordable price, coupled with longevity and low maintenance requirements, makes it a cost-effective material. The ability of galvanized steel to reflect sunlight also makes it an energy-efficient choice, reducing cooling costs.

Stainless Steel Characteristics in Roofing

When stainless steel is processed by a metal roofing machine, it results in roofing materials that are incredibly strong, durable, and visually striking. The chromium content within stainless steel prevents rust and corrosion, ensuring that the roof remains intact even in highly corrosive environments.

Aluminum’s Role in Metal Roofing Machines

Corrosion Resistance of Aluminum

Aluminum demonstrates excellent corrosion resistance, which is particularly beneficial for coastal regions where saltwater can cause deterioration. When aluminum sheets are crafted using a metal roofing machine, they offer a reliable and durable roofing solution.

Lightweight and Flexibility Advantages

Due to its lightweight nature and flexibility, aluminum is considered an excellent choice for roofing materials. A metal roofing machine can efficiently shape aluminum into various forms and profiles, accommodating intricate roof designs while reducing installation challenges and structural strain.

Copper as a Traditional Choice

Longevity of Copper Roofs

Copper is notable for its extended lifespan, often outlasting the building it covers. Roofs made of copper require minimal upkeep and can endure for centuries. Crafted using a metal roofing machine, copper roofing materials provide both historical charm and modern reliability.

Patina and Its Effects on Aesthetics

The patina that forms on copper over time is not just a protective layer but also a visual enhancement. This natural aging process adds a distinct and evolving aesthetic to the building, setting it apart from other roofing materials.

The Unique Properties of Zinc in Roofing

Natural Formation of Protective Layer

Zinc possesses unique properties that make it ideal for roofing. A metal roofing machine can mold zinc into various forms, while its self-healing patina covers scratches and maintains the roof’s integrity. This natural protective layer ensures longevity and low maintenance requirements.

Environmental Benefits

The environmental advantages of zinc are considerable. Zinc is entirely recyclable and its production demands less energy compared to other metals. Consequently, zinc emerges as a sustainable option for builders and homeowners who are environmentally conscious and aiming to minimize their carbon footprint.

Understanding the different metal options available for roofing and how they are utilized by the metal roofing machine can help in making informed decisions when selecting the most suitable material for a specific project. Each metal offers unique advantages that cater to various needs and preferences, ensuring a durable, efficient, and aesthetically pleasing roofing solution.

Factors Influencing the Choice of Metal for Roofing with Machines

Climate Considerations

Selecting the right metal for roofing is significantly influenced by the local climate. Different metals react variably to weather conditions, affecting their durability and performance.

Impact of Weather Conditions on Different Metals

Weather plays a crucial role in determining the suitability of a metal for roofing. For instance, coastal areas prone to high humidity and salt exposure necessitate metals with superior corrosion resistance, such as aluminum or stainless steel. In contrast, regions with heavy snowfall benefit from the robust strength and low maintenance characteristics of galvanized steel. By recognizing these interactions between metals and climates, one can ensure the longevity and reliability of the roofing material.

Best Practices for Different Climates

When considering the best practices for metal roofing, it is essential to select metals that are suitable for the particular climate conditions. For regions that experience hot and sunny weather, aluminum’s ability to reflect heat can help in lowering cooling expenses. On the other hand, stainless steel is an excellent choice for areas that are humid or have industrial exposure due to its resistance to rust. By adhering to these best practices, one can ensure that the selected metal will effectively endure local weather patterns, thus extending the roof’s lifespan.

Architectural Design and Style Preferences

The choice of metal for roofing should also complement the architectural design and aesthetic preferences of the building.

Match with Building Styles

Different metals can enhance the aesthetic appeal of various architectural styles. For example, a copper roof can lend a historical or upscale appearance to colonial or renaissance-style buildings. In contrast, the sleek and modern look of stainless steel or aluminum fits well with contemporary architectural designs. Matching the metal type with the building style ensures a cohesive and visually pleasing appearance.

Aesthetic Value Offered by Various Metals

Metals used in roofing offer unique aesthetic values. Copper, with its evolving patina, provides a distinctive and timeless look that can enhance the architectural character over time. Similarly, pre-painted aluminum sheets available in myriad colors and finishes can cater to a variety of design needs, offering both versatility and beauty. Recognizing the aesthetic value of different metals helps in selecting a roofing material that not only performs well but also elevates the building’s visual charm.

Installation and Maintenance Aspects

The ease of installation and the requirements for ongoing maintenance are crucial considerations when selecting metal roofing materials processed by a metal roofing machine.

Ease of Installation with Different Metals

The ease with which a metal roofing material can be installed has practical and financial implications. Metals like aluminum and galvanized steel are lightweight, making them easier to handle during installation. This reduces labor costs and the time required to complete the roofing project. Copper, though heavier, can still be efficiently installed with a metal roofing machine that ensures precision and uniformity in shaping the metal sheets.

Long-term Maintenance Requirements

Maintenance is a key consideration in metal roofing. Materials like stainless steel and copper require minimal upkeep due to their natural resistance to corrosion and environmental wear. On the other hand, galvanized steel may need periodic assessments to ensure the zinc coating remains intact. Aluminum roofs, owing to their flexibility and resistance to rust, also demand low maintenance, primarily limited to cleaning debris and checking for minor damages. Understanding these maintenance requirements helps in planning for long-term care and ensuring the roof’s durability.

Cost-effectiveness and Budget Constraints

Budget constraints and the cost-effectiveness of the roofing material are pivotal in the decision-making process.

The initial expenditure for materials such as copper might be higher, but their durability and minimal maintenance can lead to reduced total ownership costs over time. Galvanized steel, recognized for its cost-effectiveness and longevity, is a favored option for budget-conscious projects. Aluminum provides a good balance between cost, durability, and visual appeal, making it a desirable choice for various architectural requirements.

By considering factors like climate, architectural design, installation ease, maintenance, and budget, one can make an informed choice when selecting metals for roofing. Each metal processed by a metal roofing machine offers unique properties and benefits, ensuring there are options available to meet varied requirements and preferences effectively.

Future Trends in Metal Roofing Materials and Technology

The landscape of metal roofing is continuously evolving. Emerging technologies and material innovations ensure that the sector remains at the forefront of sustainability, efficiency, and aesthetics. Two key areas of development include innovations in metal roofing machines and new advancements in metal alloys for roofing.

Innovations in Metal Roofing Machines

Advancements in metal roofing machine technology are transforming how roofs are fabricated and installed. Modern machines are now more versatile, precise, and efficient, catering to a wide range of metal types and roofing designs.

Precision Engineering

Recent advancements in metal roofing machine models feature precision engineering that achieves high accuracy in cutting and shaping metal sheets. This level of precision minimizes waste during manufacturing, making the process more cost-effective and eco-friendly. Additionally, the improved accuracy guarantees that each metal sheet fits perfectly, enhancing both the durability and aesthetic appeal of the roof.

Automation and Efficiency

Automation in the metal roofing machine industry is another significant trend. Machines equipped with automated features can operate with minimal human intervention, increasing production speed and reducing labor costs. Automation also minimizes the risk of human error, ensuring consistent quality across all roofing materials produced.

Customization Capabilities

Modern metal roofing machine technology allows for greater customization in roof design. Machines can now handle complex profiles and shapes, catering to unique architectural styles and client specifications. This flexibility enables builders to experiment with innovative designs while maintaining the functional benefits of metal roofing.

Integration with Digital Technologies

Advanced metal roofing machine systems are increasingly integrating with digital technologies such as AI and IoT. These integrations enable real-time monitoring and adjustments during the manufacturing process, enhancing efficiency and product quality. Additionally, data analytics can predict maintenance needs, ensuring the machines operate at optimal performance levels.

New Developments in Metal Alloys for Roofing

The evolution of new metal alloys is poised to revolutionize the performance and uses of metal roofing materials. These innovations are geared towards improving durability, sustainability, and visual attractiveness.

High-Strength Alloys

Research into high-strength alloys aims to create roofing materials that withstand extreme weather conditions while maintaining lightweight properties. These alloys combine metals like titanium and advanced composites, resulting in roofs that are incredibly robust yet easy to handle and install. The development of such materials can significantly extend the lifespan of metal roofs, offering better investment returns.

Corrosion-Resistant Innovations

Corrosion resistance remains a priority in metal roofing, especially in areas with harsh environmental conditions. New alloys incorporating elements like silicon, manganese, and magnesium are being developed to offer superior resistance to rust and corrosion. These materials ensure that roofs remain intact and functional for extended periods with minimal maintenance.

Eco-Friendly Alloys

Sustainability is a major focus, with new metallic alloys being designed to reduce environmental impact. Alloys that incorporate scrap metals and require lower energy for production are on the rise. These eco-friendly options not only support green building initiatives but also encourage the recycling and reusability of metal roofing materials, making them an excellent choice for environmentally-conscious projects.

Aesthetically Versatile Metals

The increasing demand for versatile aesthetics in roofing materials has resulted in the development of metal alloys designed to replicate the look of traditional roofing materials such as slate or wood. These modern alloys, enhanced with innovative finishes and treatments, provide the charm of conventional materials while delivering the strength and efficiency characteristic of metal. Such progress creates fresh opportunities for designers and architects aiming to blend visual attractiveness with high performance.

In conclusion, the ongoing advancements in metal roofing machine technology and the development of innovative metal alloys underscore the dynamic nature of the metal roofing industry. These trends promise to enhance the functionality, sustainability, and aesthetic value of metal roofs, making them an increasingly attractive option in modern construction. By staying informed about these future trends, stakeholders can make well-informed decisions, ensuring their roofing solutions meet contemporary standards and future demands.

Quality is of utmost importance to XINBO. Each machine undergoes three rounds of inspection before being shipped to customers. This rigorous quality inspection process guarantees that the machines meet the highest standards and are free from any defects or issues.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia