Unlock Cost Savings with Appropriate Tile Roof Panel Machines

Understanding the Importance of Tile Roof Panel Machines

The Role of Tile Roof Panel Machines in Modern Construction

Tile roof panel machines play a crucial role in the construction industry by streamlining the production of roofing materials, thereby enhancing efficiency and precision. These machines are designed to fabricate high-quality tile roof panels that meet strict construction standards while catering to various architectural requirements. In modern construction where speed and quality are paramount, investing in a reliable tile roof panel machine is essential for manufacturers looking to stay competitive. As a result, builders can ensure timely completion of projects while maintaining the durability and aesthetic quality of roofing systems.

Key Benefits of Using Tile Roof Panel Machines

The benefits of utilizing tile roof panel machines extend beyond mere production efficiency. One significant advantage is the reduction in waste due to the precision of these machines in cutting and forming materials. This leads to cost savings in both materials and labor, making it an attractive investment for construction businesses. Additionally, tile roof panel machines often allow for customization, enabling manufacturers to produce unique products tailored to specific client needs. With the ability to handle various materials, they can also cater to diverse market demands, thereby expanding business opportunities.

Features to Look for in Tile Roof Panel Machines

Essential Specifications for Optimal Performance

When you decide to invest in a tile roof panel machine make sure you look into details to ensure it works well. Factors like production capacity and durability are key well as its ability to handle different materials. Machines with computer systems help maintain accuracy during production resulting in quality panels overall. Additionally, having feeding and cutting systems in place enhances efficiency by minimizing manual work and streamlining the workflow.

Innovations in Tile Roof Panel Machine Technology

Lately, advancements in tile roof panel machinery technology have made them more efficient and functional than before. These machines now include features that enable manufacturers to monitor production parameters in time and make adjustments promptly as needed. This has resulted in quality roofing panels and significantly reduced production times. Additionally, improvements in automation and robotics have increased safety measures making manufacturing processes safer for operators and reducing the chances of error.

XINBO’s Range of Tile Roof Panel Machines

Overview of XINBO Product Lineup

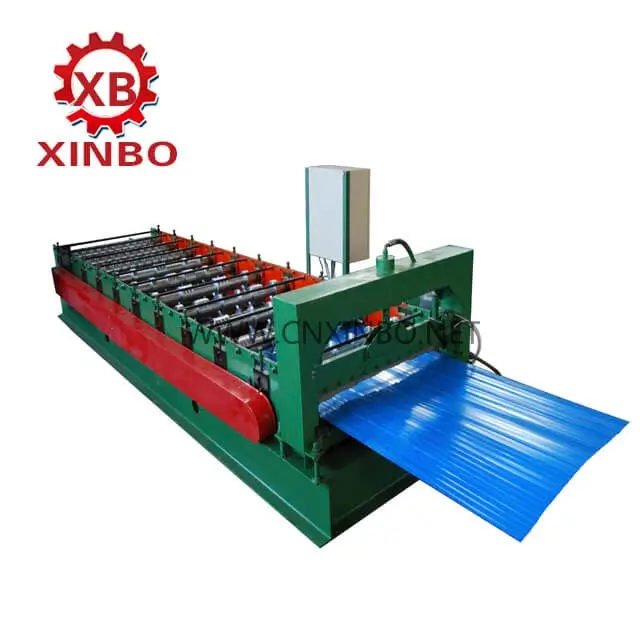

XINBO is well known for our selection of tile roof panel machines that’s perfect for different construction projects. We offer sturdy and effective machines that are specifically made to fit various types of tiles and size. XINBO is dedicated to providing top-notch quality and personalized solutions means that customers can easily find machines that match their production needs improving their operational efficiency. With a strong emphasis on originality and dependability, XINBO machines have earned the trust of construction professionals around the globe

Detailed Examination of Select Models

Model 1: Key Features and Specifications

XINBO product line includes the IBR roll forming machine is known for our efficiency and adaptability in creating top-notch roofing sheets with a shape widely used in industrial and commercial building projects. The accuracy of the IBR roll-forming machine stands out due to its control systems that oversee and maintain quality throughout every sheet it produces. Furthermore, the machines automated production functions enhance efficiency while cutting down on labor expenses.

Model 2: Unique Selling Points and Applications

XINBO also has a machine known as the One Layer Trapezoid Roof Panel Machine in our lineup. The machine stands out for our features that allow for the production of panel sizes and profiles to cater to specific market needs. The sturdy construction ensures durability and performance longevity while the cutting-edge technology utilized in our production process ensures the quality and resilience of the end product. The One Layer Trapezoid Roof Panel Machine is perfect for large-scale manufacturing to meet the growing need for notch roofing solutions in construction projects.

Steps to Integrate Tile Roof Panel Machines into Your Operations

Initial Setup and Training Requirements

Incorporating tile roof panel machinery into your production processes necessitates planning and instruction to enhance effectiveness and output levels to their potential. The first phase entails selecting a spot within your establishment that enables workflow while considering areas for storing materials and products in progress or completion. Team members and auxiliary staff need training on the tile roof panel equipment obtained from XINBO to grasp operational protocols and safety precautions crucial for a smooth-running process. Employees undergo training to become well-versed in the features of the machine and our software controls and maintenance needs to minimize errors and accidents while operating it.

Ensuring the machine is set up correctly to meet your production needs is a step in the configuration process according to XINBO’s recommendations for optimal performance aligned with your output requirements; therefore, it’s important to communicate any specific preferences you may have in mind regarding settings needed for operation purposes. After the machine is up and running smoothly following the setup phase trial run to, assessing its efficiency is suggested as a means to make adjustments if deemed necessary. Implementing a training schedule for education related to operating the tile roof panel machine will not only boost its performance but also contribute positively towards maintaining a safe working environment.

Ongoing Maintenance and Support from XINBO

To keep tile roof panel machines working well for a time and performing XINBO has a detailed maintenance plan that involves regular checks and steps to prevent issues from arising. The program helps detect problems early on to avoid larger complications and lower maintenance expenses XINBO skilled technicians are available to guide users on the proper upkeep tasks, like cleaning lubricating and replacing worn out parts.

XINBO also stresses the significance of keeping operators skilled and up to date in our work tasks through training sessions to refresh our knowledge of the techniques for operating and maintaining machinery effectively. Additionally, addition hotline for users to reach out for expert guidance swiftly in case of any problems with their tile roof panel machine helps reduce downtime. Promotes a culture of ongoing enhancement within the company.

Realizing Long-Term Savings with XINBO’s Tile Roof Panel Machines

Strategies for Maximizing Cost Efficiency

Achieving optimal cost effectiveness in the utilization of tile roof panel equipment requires the implementation of methods throughout the manufacturing process. One successful approach is to examine production workflows to pinpoint bottlenecks and optimize procedures effectively. Guaranteeing material flow from one phase to another stage in production operations can be. Cycle times reduced leading to enhanced productivity. Incorporating manufacturing principles in conjunction with the use of XINBO machinery can result in decreased wastage and better management of resources that directly influence profitability.,

One important factor to keep in mind is maximizing the use of materials efficiently. Using the accuracy features of tile roof panel equipment reduces waste. Allows producers to make use of top-notch raw materials. Selecting materials that match the machinery’s production method helps firms enhance product resilience and appearance resulting in customer approval ratings and returning clientele. Moreover, establishing collaborations with suppliers can result in reduced costs for buying materials in bulk thus adding to lasting financial advantages.

Additional Resources and Tools from XINBO

XINBO not only provides machinery but also offers a range of resources and tools to help manufacturers save costs and enhance operational efficiency. The availability of documents and user manuals ensures that operators are equipped with the necessary information to effectively use the machines.

In conclusion, integrating tile roof panel machines into manufacturing processes significantly contributes to enhanced operational efficiency, quality of output, and cost savings. XINBO’s focus on providing comprehensive support, advanced technology, and proactive maintenance plans ensures that clients can fully harness the potential of their investments, driving business growth in a competitive market. By strategically managing resources and continuous learning, companies can cultivate a sustainable production environment and consistently meet the evolving demands of the construction industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia