Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

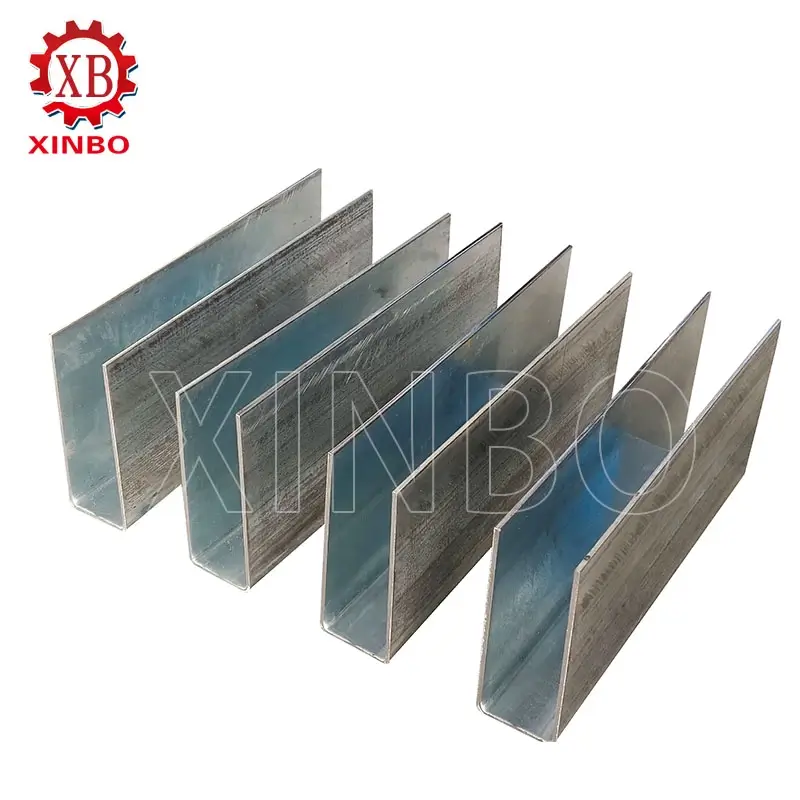

VIEW MORE→A U channel roll forming machine is a special type of industrial machine used to make long U-shaped metal profiles from flat metal coils. These profiles are widely used in construction and infrastructure projects. The machine slowly bends the metal using a series of rollers until it takes on the correct shape. These machines are built to handle long production runs with consistent quality, which makes them popular in many industries.

Roll forming is a continuous bending process. It starts with a coil of metal being unrolled and fed into the machine. As the metal passes through a series of roller stations, each station bends the metal a little more until the final U shape is formed. The advantage of this method is that it can create complex profiles with smooth curves, high precision, and no material waste. Unlike other metal shaping methods like stamping or welding, roll forming is more efficient for long and thin profiles like U channels.

A typical u channel forming machine includes an uncoiler, a feeding guide, roll forming stations, a cutting unit, a control system, and sometimes a stacking system. The rollers are usually made of high-strength steel or alloy, which can handle the pressure and wear from long-term use. The cutting unit can be hydraulic or servo-driven for better accuracy. A touch screen PLC system controls the entire machine, allowing operators to set different parameters like length, speed, and material thickness.

U channel roll forming machines usually work with galvanized steel, aluminum alloys, stainless steel, or other coated metals. These materials are chosen for their strength and ability to resist rust or corrosion. The machine must be able to handle various thicknesses, often from 0.5mm to 3mm, depending on the application. The quality of the input coil affects the performance of the machine and the final product.

U channel forming machines are used in many areas of construction and infrastructure due to their ability to produce strong, lightweight profiles. The demand for reliable China u channel forming machines has increased globally due to their competitive pricing and advanced technology.

In roofing systems, U channels serve as supports for gutters and drainage pipes. They help manage rainwater and protect building structures. The precise size and smooth surface of the U channels ensure proper water flow and prevent leaks. A machine to create u channel for roofing systems needs to support a variety of widths and thicknesses to meet different building codes.

For wall panel framing, U channels act as connectors between other metal profiles and help maintain the stability of the wall. These profiles must be perfectly straight and strong. A high-efficiency u channel roll forming machine is essential to produce these framing parts with minimal deviation, even during high-speed production.

Bridges need to handle expansion and contraction due to temperature changes. U channel profiles made with high-precision machines are used in the joint areas to hold expansion parts together. The ability of an OEM u channel roll forming machine to produce exact sizes makes it ideal for such critical infrastructure.

Guardrails use U channels to add strength to the structure and absorb impact. These channels are made from thick steel to ensure safety. A good u channel forming machine supplier will offer solutions that work with thicker materials and produce heavy-duty profiles efficiently.

Modular construction uses pre-made metal frames, and U channels play an important role in supporting walls, ceilings, and floors. These parts must be made quickly and accurately to match the tight timelines of modular construction. That’s why a reliable china u channel roll forming machine is a valuable asset for these projects.

Selecting the right machine depends on your business goals, product requirements, and budget. The design and output capacity of the machine should match your actual production needs.

The speed of the machine is often measured in linear meters per hour. If your business needs to produce large volumes, look for machines that can run at higher speeds without sacrificing accuracy. Advanced u channel roll forming machines can reach speeds of up to 20–30 meters per minute.

Your machine must handle the range of metal thicknesses you plan to use. A good model will allow for easy adjustments to roll settings and can work with both light and heavy materials. Some OEM u channel roll forming machines are designed with flexible configurations to support a wide thickness range from 0.5mm to 3mm.

Many customers need special U channel shapes or dimensions. A reliable u channel forming machine supplier like Xinbo can offer CNC-based customization to meet these needs. Their ability to produce custom dies in-house helps reduce lead times and ensure precision.

Choosing between an OEM solution and a standard machine depends on whether you need special profiles or just general-purpose U channels. OEM machines are more flexible and tailored, while standard machines are faster to deliver and easier to operate.

First, a metal coil is loaded onto the uncoiler. The sheet is pulled into the feeding guide, which straightens and aligns it. The first forming rollers apply a light bend, preparing the sheet for the next stages.

The sheet then moves through multiple roller stations. Each set of rollers bends the metal a little more until it reaches the final U shape. The number of roller stations affects the product quality. The more stations, the smoother the bends and the better the precision.

After forming, the profile is cut to the required length using hydraulic or servo cutters. These systems offer cutting accuracy within ±0.5mm. After cutting, an automatic stacking unit arranges the finished products neatly for packaging or storage.

Xinbo’s CNC workshop is able to create custom dies in as little as 72 hours. This means customers can get a machine to create u channel for new or custom designs much faster than normal. This rapid response is especially helpful for urgent projects and prototype testing.

The rollers are made from alloy or high-carbon steel for long life. They are mounted on a modular system that makes replacement or repair easy. High-quality rollers ensure the final product is straight and strong.

Modern machines use PLCs with touch screen displays. These systems remember the settings for different jobs, show errors on the screen, and allow operators to make quick adjustments.

Compared to older pneumatic systems, hydraulic servo cutters are more accurate and energy-efficient. They ensure consistent length and reduce waste.

Xinbo machines undergo three inspections to ensure the roller alignment is within 0.01mm. Their smart designs also reduce container size, which helps customers cut shipping costs by up to 15%. These features make Xinbo one of the leading u channel forming machine suppliers in China.

Always keep the moving parts, especially rollers and chains, well-lubricated to avoid wear.

Wipe the rollers clean daily to prevent dirt or metal buildup, which can damage the surface of the U channel.

Check for unusual noises or uneven cuts, which can mean a misaligned roller or dull blade.

Have the machine professionally inspected once every 6–12 months to keep it in peak condition.

What’s the minimum order quantity for custom U channel machines?

Usually, one set is enough to start, especially with an OEM u channel roll forming machine.

How does climate affect U channel material selection?

Humid or coastal climates need corrosion-resistant materials like galvanized or coated steel.

Can existing roll forming machines be retrofitted for U channels?

Yes, but retrofitting may not be cost-effective if major changes are needed.

What safety certifications should U channel machines have?

Look for CE, ISO9001, and other local safety standards.

Why choose Chinese manufacturers over local suppliers?

China u channel forming machines are more cost-effective, offer advanced features, and come with strong after-sales service.

Like precision-engineered U channels that form the backbone of modern structures, choosing the right manufacturing partner forms the foundation of your production success. Whether you’re building skyscrapers or highway barriers, our engineers can help you create the perfect metal profile solution. Click the chat icon to receive a free project assessment and discover how our 72-hour rapid prototyping service can accelerate your timeline.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→