Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→The Standing Seam Roof Panel Roll Forming Machine is among the most important machinery in modern construction and roofing industries. These machines are well-known for making good-quality standing seam roof panels with efficiency, and such panels play a very critical role in giving long-lasting, durable, and efficient roofing solutions. With their versatility and precision, these machines can easily operate from residences to heavy industries.

Due to the demands of businesses in the roofing industry for quicker and quicker production processes, the importance of choosing the appropriate Standing Seam Roof Panel Roll Forming Machine cannot be underestimated. In this blog, we are going to discuss what the machine is, the various applications it finds, its key features, and factors you should consider when purchasing the machine.

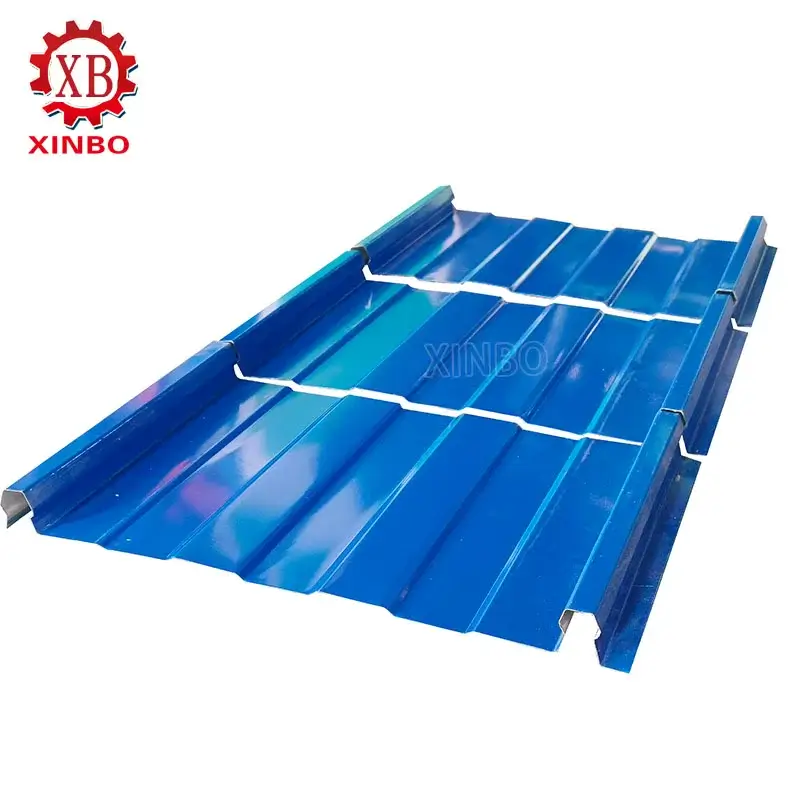

A standing seam roof panel roll-forming machine is an industrial machine that is used in the making of standing seam roof panels, very well recognized by their sleek look and durability. These machines process coils of materials like PPGI: Pre-painted Galvanized Steel, GI-Galvanized Iron, and aluminum into precisely formed roof panels with interlocking seams. The interlocking seams, which are excellent in terms of weather resistance, perform exemplary on both flat and sloping roofs.

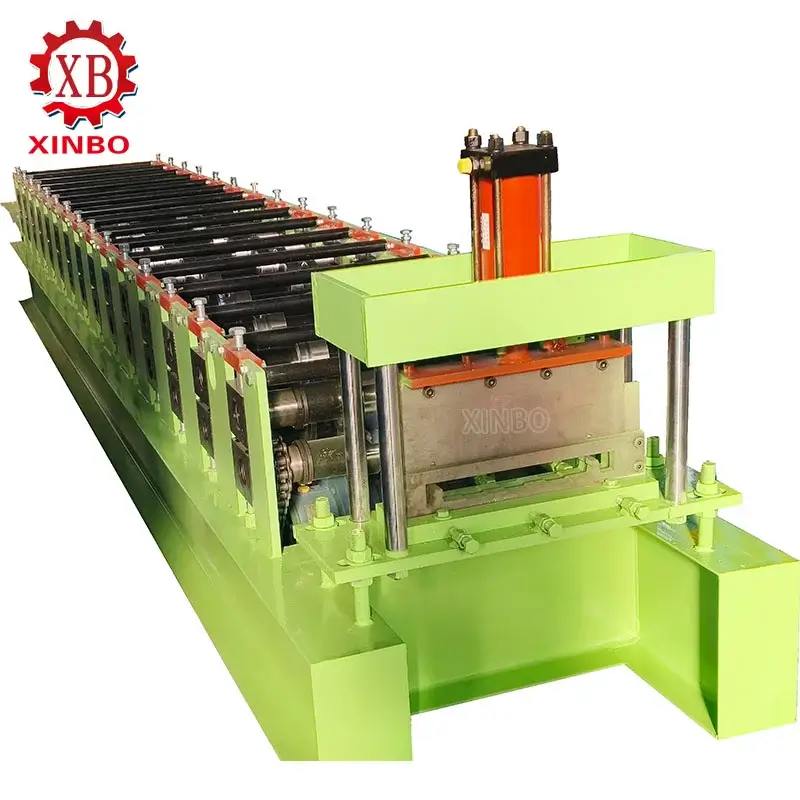

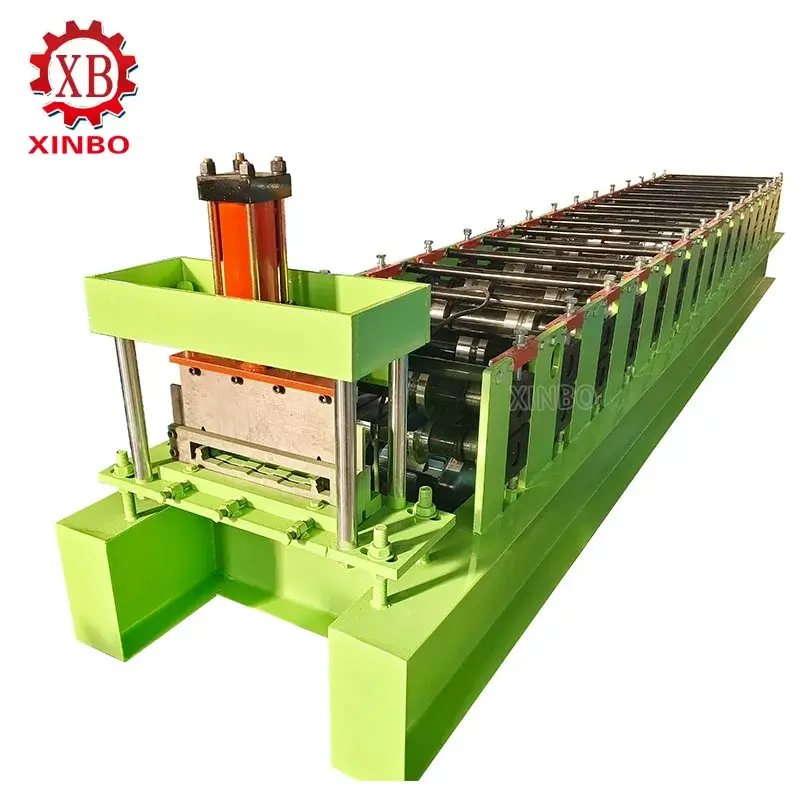

This is achieved when the machine uncoils the material and then feeds it through a series of rollers that give the metal the desired profile. The process generally termed, assures consistency at high speeds with minimal waste. These range from different roofing panels applied from small residential homes to large commercial buildings.

Standing Seam Roof Panel Roll Forming Machines find their applications in various industries that use strong and weather-resistant roofing solutions. The main sectors where these machines find their applications are as follows:

Seam roofing panels are employed for the residential projects because of their attractive look and long durable effect. Roofing panels are resistant to snow, heavy rainfall, and strong winds that can support residential construction in harsh weather conditions.

From office buildings to retail shops, standing seam roofing machines are widely applied to commercial buildings. Due to its toughness and low maintenance it requires, seam roofing panels become the perfect solution for business owners willing to invest in long-term roofing investments.

Industrial roofs are in dire need of materials that will withstand heavy loads of snow, ultra-high temperatures, and constant exposure to weathering elements. Standing Seam Roof Panel Roll Forming Machines manufactured by these machines are ideal for such environments and offer strength and resilience, very essential in large manufacturing plants and warehouses.

When investing in a Standing Seam Roof Panel Roll Forming Machine, it is good to know what features make the machine efficient, productive, and performant. Here are some of the key features that define excellence in a machine. Features of a Quality Machine:

The design of modern standing seam metal roof machines provides automation for them to run with little interference from human beings. This will ensure an increase in the production speed while the errors are reduced to a constant. Machines can be found in customized production speed usually between 0 to 15 meters per minute.

These machines are designed for solidity and can work on a large variety of material types, including coils of PPGI, GI, and aluminum. The 45# forged steel roller is of high strength and durability due to heat treatment with hard chrome plated. The frame is welded using H-beams for added stability, and the rollers ensure the panels are formed correctly.

Another reason for its popularity is the ease of use factor. Almost all the models involve buttons and touchscreen combinations so that workers can operate it conveniently, even though most of the workers have limited experience. Usually, the operations are controlled with PLC or the Programmable Logic Controller to ensure high accuracy with perfect consistency.

Seam roof panel machines can be tailored for very specific needs of different industries. The thickness of the material processed generally ranges from 0.3mm to 0.7mm, while the speed of production and width of the coil can also be changed. Thus, buyers can choose machinery that will best fit their production needs and give the most economic efficiency.

XINBO was founded in 2014 and is one of the leading companies involved in the manufacturing of Roll Formers for Standing Seam Roof panels in China. It offers among the best Standing Seam Roof Panel Roll Forming Machines in the industry. Backed with more than a decade of experience in this business, Xinbo provides excellent products from a professional team of engineers and designers who make sure every machine will be of high quality.

The biggest advantages of working with Xinbo are a personalized approach, more specifically-our possibilities of making customized services available to our customers: the ability to offer customized machine designs, including accurate technical drawings that assure the final product will turn out exactly as ordered. Equipped with all new facilities-including in-house CNC machining and workshops-they make sure the process of production is very effective. Besides this, one should take into consideration the competitive price, the rather short terms of delivery, and a very good level of customer service.

Xinbo Standing Seam Panel Machines assemble advanced operation, high productivity, and high quality control features. The machines shall handle a variety of materials for you to produce tough and long-lasting panels. After-sales commitment to quality is manifested in the various checks that this product undergoes during different stages of its production.

The rollers are made from 45# and undergone heat treatment for strength. All the panel formations are well and consistent because a PLC control system was utilized for this purpose. Moreover, the business can be guaranteed of high productivity by using their machines with minimum maintenance.

There are a number of things that you should look for when buying a standing seam roof panel roll forming machine to great value for your money. Here are some of the key things you may want to look at:

Check the type of material a machine can process. A good machine should be able to handle several materials, including PPGI, GI, and aluminum coils, without affecting the quality of the finished panels.

Ensure that the machine’s capability for production will answer your needs in business. These machines are able to allow production at variable speeds such as 0 to 15 meters per minute depending on what the project requires.

Different projects are present in various panel sizes and configurations. Find a machine with options like setting coil widths and the thickness of panels so that any specific needs your roofing project may have will be met.

In today’s competitive market, energy efficiency is a crucial consideration. Choose a machine that offers low power consumption while maintaining high output. Machines that use a PLC control system tend to be more energy-efficient and easier to manage.

It will be wise if you choose a manufacturer who can offer after-sales support concerning maintenance services as well as spare parts. With a good supplier like Xinbo, you can always seek help as soon as possible and continue with your operations smoothly.

The standing seam roof panel roll-forming machine is an indispensable asset to any roofing company; it will provide a very affordable, durable, and effective way to manufacture high-quality roof panels. With high productivity, custom features, and precise engineering, this machine will let a business provide the best roofing products-from residential houses to large-scale industrial facilities.

Other key features considered in the selection of any machine include the compatibility of the machine with the material being processed, production capability, and prestige of suppliers. With years of activity, Xinbo earned such a reputation as a manufacturer to tend to offering one of the best: a standing seam roof panel roll-forming machine that exists in the market nowadays. Value for money means attention to quality, quick completion of projects, and after-sales service-all these make them trusted, in fact, to become your partner not only in the local scene but also for worldwide roofing businesses.

For more information and discussions, please contact Xinbo today and let the journey begin to make your roofing production processes even better. You can reach them via phone at +008618713731132, or email at serena@cnxinbo.net.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→