Top-Quality Bottom Beam of Shutter Door Roll Forming Machine from China’s Leading Manufacturers

When considering the manufacturing of high-performance shutter door systems, one of the most critical components is the bottom beam of the shutter door roll forming machine. The bottom beam ensures the stability and structural integrity of the entire door system, playing a significant role in both the functional and aesthetic quality of the final product. This blog will explore what defines a top-quality Bottom Beam of Shutter Door Roll Forming Machine, its applications, why choosing Chinese manufacturers is a smart decision, future trends in Bottom Beam of Shutter Door Roll Forming Machine technology, and answer some frequently asked questions regarding these machines.

What Defines a Top-Quality Bottom Beam of Shutter Door Roll Forming Machine?

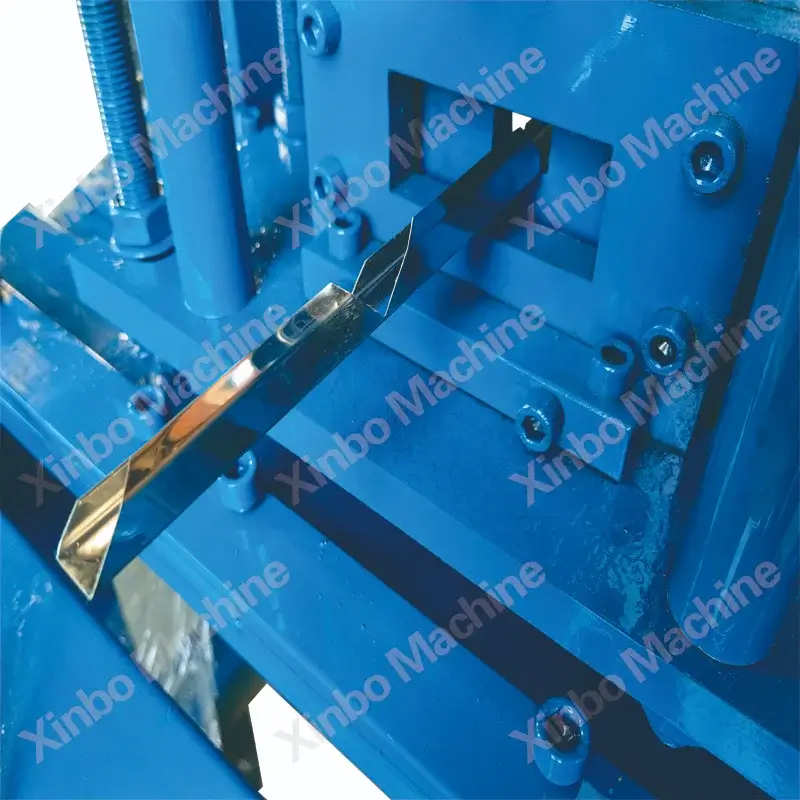

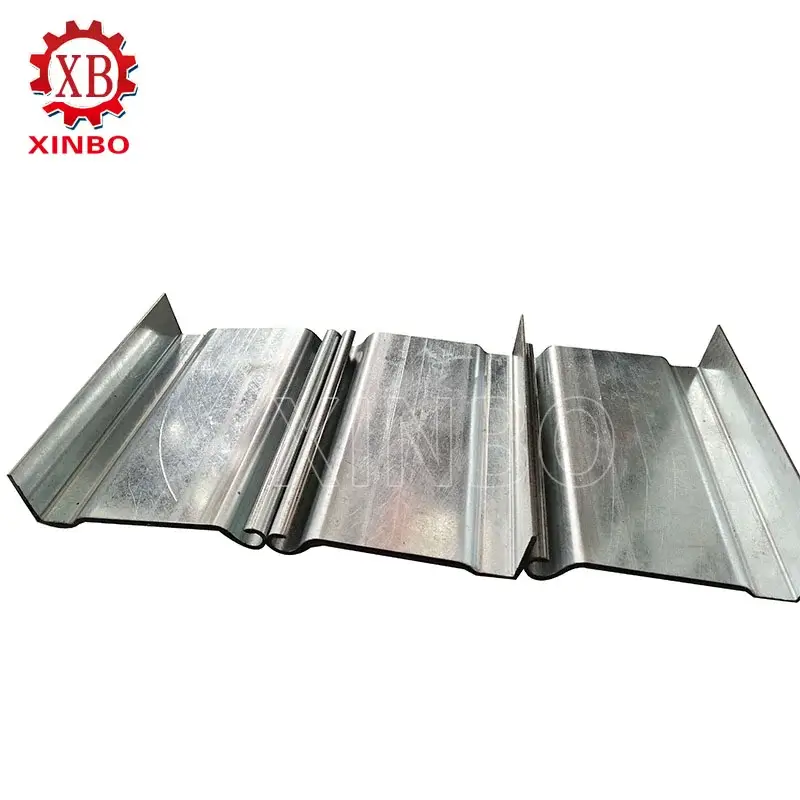

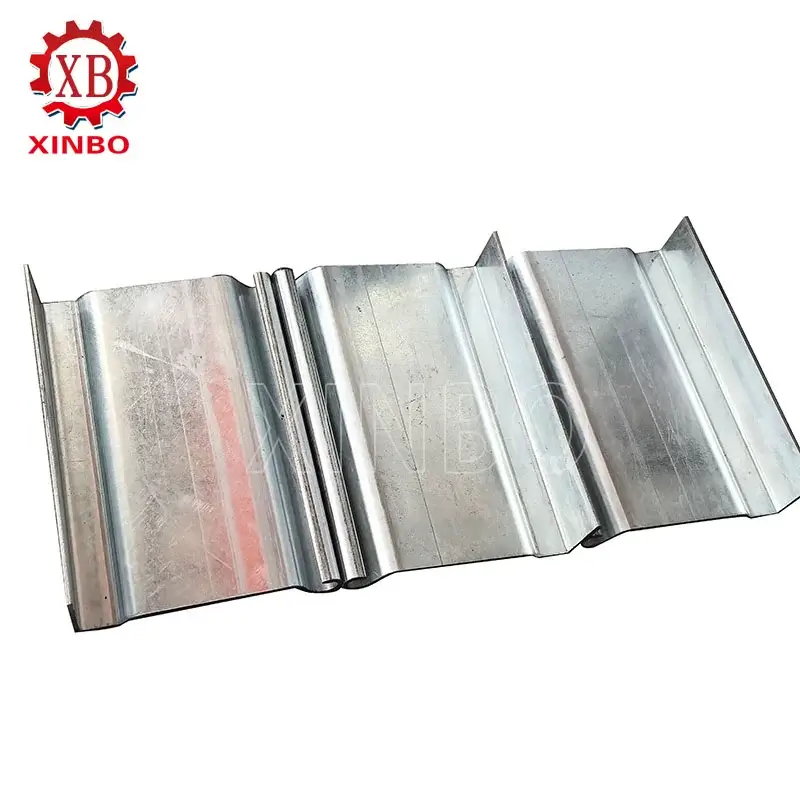

Precision Engineering for Durability

The Bottom Beam of Shutter Door Roll Forming Machine is crafted with care. This ensures it lasts and performs well over time. Choosing the right material matters a lot. The beam must handle tough conditions for years. Top makers often pick high-grade galvanized steel. It fights rust well, especially outdoors. Anti-rust coatings get added too. These boost the beam’s ability to resist corrosion and stay solid. The beam’s design must spread weight and pressure evenly. This keeps shutter doors running smooth. It also helps them take daily wear without breaking down.

Advanced Functional Features

Today’s shutter door roll forming machines come with smart upgrades. These boost both output and ease of use. Many have auto-adjustments that save energy. They cut waste and power use during production. Plus, they often work with clever control systems. These tweak settings using live data. It sharpens accuracy and lowers mistakes. Such setups ensure the bottom beam is made with top precision and steadiness. This cuts flaws and speeds up the building process.

Rigorous Quality Assurance Standards

Great bottom beams don’t just happen. They come from strict quality checks. China’s top makers put their machines through tough tests. These include load strength reviews, alignment tests, and performance runs. Such steps confirm the beam can tackle heavy-duty jobs. Beyond in-house checks, many hold ISO and CE certifications. These prove the machines meet global standards. They give buyers confidence in reliability and safety.

Key Applications of High-Performance Bottom Beam Roll Forming Machines

Industrial & Commercial Shutter Door Production

The bottom beam is vital for making shutter doors in industrial and commercial spots. Warehouses, plants, and stores need doors that lock tight and stand up to weather. A strong bottom beam keeps these doors steady and safe, even in rough conditions. Its toughness stops sagging or twisting. This keeps doors working and secure for ages. With growing calls for solid security, top-quality bottom beams are more crucial than ever.

Custom Solutions for Unique Architectural Projects

Beyond standard uses, high-performance bottom beams fit custom building projects too. Some structures need curved or oversized doors for special designs. Makers can craft tailored beams for these jobs. These ensure the doors stay strong and move well. Modern roll forming machines bend to these needs. They’re perfect for bold, high-end building work.

Integration with Automated Door Systems

The bottom beam also ties into automated door setups. As buildings get smarter, automation is key in homes and businesses. The beam helps form shutter doors that open and shut on their own. No handwork needed. These setups shine in busy spots like malls or warehouses. There, ease and safety matter most.

Why Choose China’s Leading Manufacturers for Your Roll Forming Needs?

Cutting-Edge Technology at Competitive Pricing

China leads the world in making goods, including roll forming machines. Its makers pour funds into the latest tech. This keeps their products sharp globally. Their low costs don’t skimp on new ideas. In fact, they lead in using auto-controls and precise crafting. This makes them a go-to for firms aiming to streamline production.

Scalable Production Capabilities

A huge perk of Chinese makers is their flexible output. Need one custom unit or a big batch? They’ve got it covered. They can whip up prototypes fast or handle mass orders with slick shipping. Many top firms have worldwide delivery networks. This means machines reach you anywhere, quick and smooth.

XinBo Customization Service: Tailored to Your Specifications

For Customization Service, top Chinese makers like XinBo step up. XinBo customs Bottom Beam of Shutter Door Roll Forming Machines to fit your needs. They adjust for unique designs, material picks, and output sizes. This customization boosts efficiency and output quality for buyers.

Future Trends in Roll Forming Machine Technology

Sustainability in Manufacturing

As green goals grow, sustainable making gains ground. Makers explore recyclable materials and power-saving methods. They aim to cut their environmental mark. This includes greener raw materials and leaner energy use. Roll forming machines are getting designed to use less power. This shrinks their carbon footprint.

Modular Designs for Faster Upgrades

Modular setups are a rising trend in roll forming tech. They bring big wins. With swappable parts, makers can update systems fast. No long downtimes needed. These setups let production lines shift quick to new tech or needs. No full gear overhaul required.

FAQs About Top-Quality Bottom Beam Roll Forming Machines

How long does a high-quality bottom beam typically last?

A bottom beam’s life hinges on materials and crafting quality. With good care, beams of galvanized steel can last years. They hold up in harsh settings too.

Can these machines handle custom thickness or profiles?

Yes, modern roll forming machines adapt well. They manage various thicknesses and shapes to match your project spot-on. XinBo’s customization offers top flexibility for scales and materials.

What safety features are integrated into modern roll forming machines?

Today’s machines pack safety tools like emergency stops and overload guards. They meet global safety rules too. This keeps workers safe while keeping output high.

How do I verify the quality of a Chinese manufacturer’s products?

To check quality, ask for samples and do factory visits. Look for ISO or CE badges from third parties too. These steps confirm global standards are met.

Ready to Elevate Your Shutter Door Production?

See how China’s top engineering can boost your shutter door setups. Reach out XinBo today to check XinBo’s fresh solutions. Or grab our technical guide for deep dives into benchmarks and best practices.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia