Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→A metal door frame roll forming machine holds a crucial spot in today’s building industry. This device crafts sturdy and tidy door frames. It shapes metal sheets into flawless door frame profiles. These machines are commonly used to create steel door frames. Such frames appear in houses, offices, factories, and public structures.

Lately, the demand for top-notch steel door frame making machines has surged. Builders and makers seek quick, dependable, and automated tools. They want to produce more in less time. A superior machine ensures precise frames. This leads to better-fitting doors and fewer issues later.

Xinbo, a reliable brand since 2014, is famous for its tailored metal door frame machines. They offer clever solutions and high-quality designs. These meet the needs of clients worldwide. Whether the task is simple or tricky, Xinbo’s machines are built to tackle it.

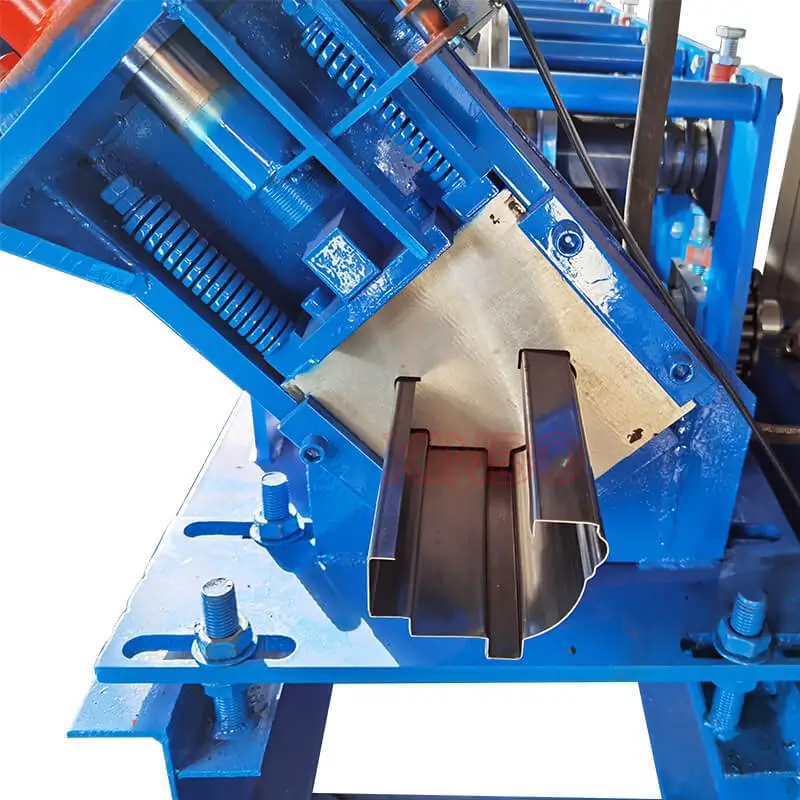

The primary role of a metal door frame machine is profile shaping. This process creates neat and uniform frame shapes from metal sheets. The metal door frame profile machine uses rows of rollers. These bend the metal into the desired shape as it passes through.

Another fantastic trait is material flexibility. These machines can handle various metals, like steel, aluminum, and galvanized sheets. This versatility lets makers choose materials based on specific needs and budgets.

Applications of metal and steel door frame machines are widespread. They serve homes, business offices, and even factories. These machines produce robust frames that last for years.

The quality of a steel door frame roll forming machine relies on its parts. One vital part is the roll forming stations. These are sets of rollers that mold the metal. More stations often mean sharper precision and smoother edges.

Another essential component is the cutting system. Most machines now use hydraulic or servo-driven cutters. These deliver clean, exact cuts at the correct length and angle. This is key for a perfect fit.

Modern machines also feature control systems, like PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces). These make the machines simpler to operate. They also allow better management of the process. When using an automatic metal door frame machine, smart controls reduce mistakes and boost speed.

Material feeding systems, like decoilers, ensure metal sheets enter the machine smoothly. This prevents stops and keeps the operation swift and effective.

The operation of a steel door frame machine follows several key steps.

Step 1: Material Loading – The metal coil is placed into the decoiler of the metal door frame roll forming machine. This starts the process.

Step 2: Forming Process – The metal moves forward. It passes through rows of rollers. These gradually shape it into a door frame profile.

Step 3: Cutting and Bending – Once the shape is formed, the machine cuts the metal to size. It also bends it at the right angles.

Step 4: Quality Check – Before the frame leaves, the machine checks the product. This ensures it meets the required standards.

Xinbo uses a unique three-stage quality inspection system. This guarantees each steel door frame machine produces sturdy, clean, and precise results.

When crafting door frames, accuracy is vital. A tiny error in angle or cut can make the door fit poorly. That’s why choosing a machine with advanced PLC systems is crucial. These systems carefully control the cutting and bending process.

Xinbo’s automatic metal door frame machines undergo three separate checks before shipping. This ensures each machine creates consistent and exact door frames.

Every project varies. Sometimes, you need a non-standard door frame. A quality metal door frame making machine should support custom designs.

Xinbo’s team provides special custom design services. Their engineers create unique plans for each metal door frame profile machine. This ensures the machine perfectly matches the shape and size you need for your project.

Machines for steel door frame production work hard daily. That’s why strong construction matters. The body of the steel door frame machine should use top-quality materials. These can withstand heavy use.

Xinbo builds its machines in its own facility. They use CNC machining for precise fits. This makes their metal door frame roll forming machines more durable. They are less likely to break down.

Modern factories demand speed and precision. An automatic metal door frame machine delivers both. These machines need minimal manual effort.

Look for machines with servo motors and touch-screen controls. These enable easy operation and faster production. Xinbo’s machines are designed to fit inside 20 or 40-foot containers. This makes them simpler to ship and install at your site.

A user-friendly design is highly valuable. Not every operator has advanced training. So, the metal door frame making machine should be easy to understand and use.

Xinbo creates machines with clear guides and touch screens. They also provide training and support. This helps new operators learn quickly. It lets them use the machine confidently.

Xinbo machines feature cutting-edge technology. This boosts the speed and quality of steel door frame production. They also offer tailored solutions for unique needs. Whether you need a new profile or a specific shape, Xinbo can build it for you.

Xinbo constructs their metal door frame machines in-house. This ensures better control of cost and quality. Their equipment is tested and dependable. You can rely on it daily.

With a Xinbo steel door frame roll forming machine, you save time and money. You also get better results.

Start by considering your project’s needs. What type of metal will you use? How many door frames do you need to produce? How complex is the design? These questions guide you to the best steel door frame machine.

Next, check the support the manufacturer provides. Can they offer training? Can they fix or upgrade the machine? Xinbo provides all these services.

Finally, balance cost and quality. A cheap machine may save money now. But it could cost more later. A reliable steel door frame bending machine will last longer. It will perform better with fewer issues.

Choosing the right metal door frame roll forming machine requires evaluating several features. Precision, customization, sturdy build, automation, and ease of use all matter. A great machine can transform how you produce door frames.

Xinbo has proven to be a dependable partner for businesses needing steel door frame roll forming machines. Their focus on quality and service makes them a wise choice.

Selecting the right metal door frame making machine can revolutionize your production process. It saves time and boosts quality. Curious about how a Xinbo metal door frame roll forming machine can meet your unique needs? Contact our team for expert advice and custom solutions tailored to your projects!

Don’t let outdated tools slow you down. Email us today to explore how our automatic metal door frame machines can elevate your manufacturing game!

Ready to dive deeper into the world of steel door frame production? Visit Xinbo’s website to discover innovative metal door frame profile machines designed for your success!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→