Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

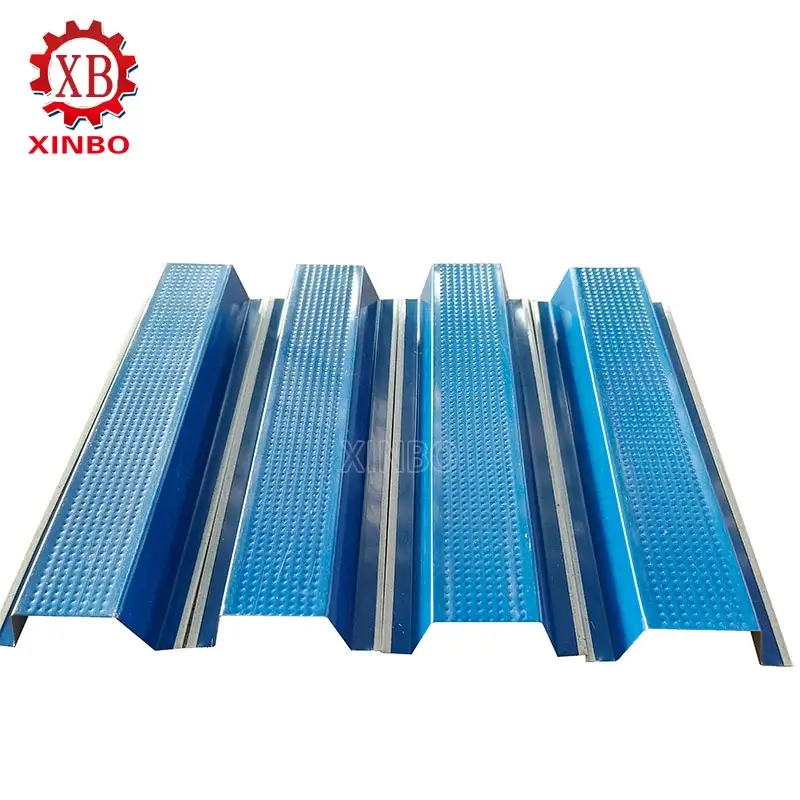

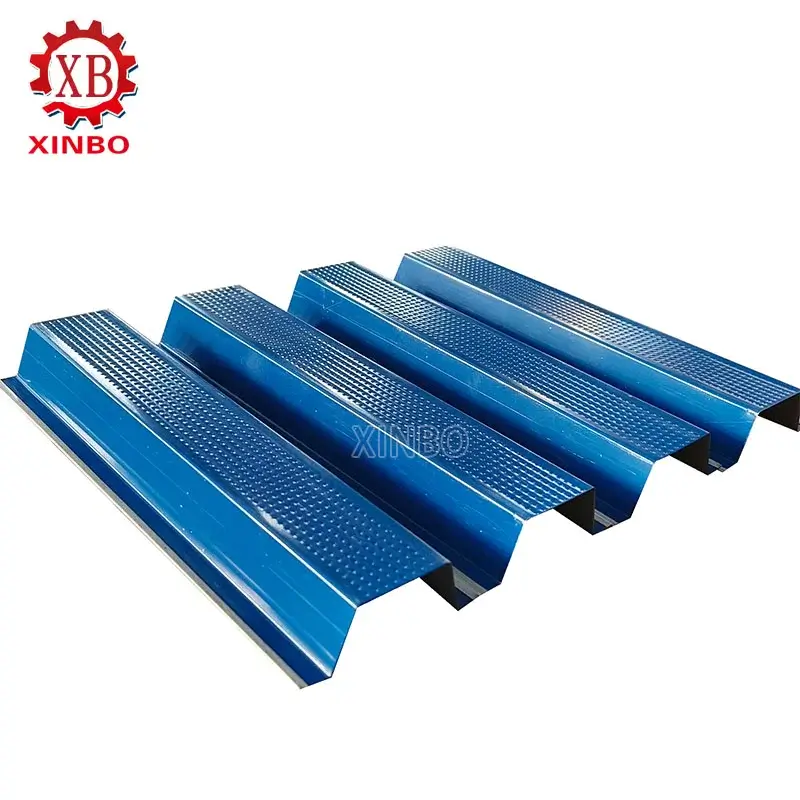

VIEW MORE→Furring channels form an important part of the construction process, where they are used for wall and ceiling support. These channels basically create a space between the structure and the finishing material. An Omega furring channel roll forming machine is designed to manufacture these channels in large quantities from metal coils in an effective manner. The machine changes flat metal strips into accurate omega-shaped channels through a series of rollers. These machines are very important in ensuring high-quality and consistent output for various construction needs.

A good Omega Furring Channel Roll Machine should have several key features to ensure efficiency and accuracy in production:

Material Compatibility: It has to work on a wide variety of materials like steel, galvanized steel, aluminum, and PPGI coils according to the needs of different projects.

Precision Rollers: The high-quality rollers made of durable materials, such as 45# steel with heat treatment and hard chrome plating, are used in the precise forming of channels.

Adjusting Settings: Machines must provide different settings depending on the channel size and thickness.

Automated Operation: A good machine should have an automated system that minimizes manual labor intervention and produces goods with consistent quality.

Cutting Mechanism: The hydraulic cutting mechanism in a machine should be such that it makes clean and accurate cuts.

PLC Control System: PLC system with a user-friendly interface for precise operation and control.

High Speed: Some high-speed machines can go up to 120 m/min.

Durability : The machine should have been constructed from hard frames. Their normal steel and other square pipe weldings allow the required strength to come out with all ways.

Omega furring channels, which are possible by such particular machines, have wide usage in various settings.

Level Surface Creation: Furring channels make for even surfaces on the most uneven of walls and ceilings. ·

Soundproofing and Insulation: They allow easy installation of insulation and soundproofing materials inside walls and ceilings. ·

Metal Siding: Furring channels are used to secure the attachment of metal siding to steel studs or masonry. ·

Suspended Ceilings: Together with cold-rolled channels, they form a perfect system for drywall ceilings.

Various uses of the Omega furring channel provide an immense scope for the Omega Furring Channel Roll Machine to become a very vital instrument in the line of construction.

Chinese manufacturers are the buzz in the international machinery market for several reasons including:

Competitive pricing:Chinese manufacturers do offer competitive pricing owing to the low cost of production that makes high-quality machinery accessible.

Technological Advancement: Many manufacturers from China invest in up-to-date technologies and engineering to provide machinery that is reliable and effective.

Customization Options: Chinese suppliers are fairly flexible and may always agree to customer customization of machinery.

Scalability: Most factories in China are able to increase production and deal with large orders, hence ensuring big projects’ demands are met.

Wide Variety: There is a wide range of manufacturers producing various types and configurations of roll-forming machines, which increases the likelihood that you will find the right fit.

Xinbo is one of the well-known manufacturers of metal shaping and roll-forming machines in China with over 10 years of experience. They are a 100% manufacturer focusing on producing quality machines that solve the various demands of their customers. Some of the various solutions that they are offering include roll-forming services, Omega furring channel making machines, custom designs according to customers’ requirements, and others. Their stress on technology, quality, and customer service over the years has earned them much prestige in this field.

There are several definite advantages in your selection of the Omega Furring Channel Roll Machine from Xinbo:

Custom Design: With a back-up of professional engineers and designers, Xinbo can provide detailed drawings according to customer requirements within short periods. They ensure that the machinery precisely matches the required profile and design.

Competitive Pricing: Having their own workshop, CNC machining, and skilled manpower, the prices that Xinbo offers are competitive.

Fast Delivery Time: The inhouse design and fabricating by Xinbo allow for short delivery time.

Quality Control: Every machine before shipment undergoes three times test. These make sure that parts and profiles needed by the client are met in addition to that the machines works perfectly.

Comprehensive Service: UL, TUV, CE, CQC, ROHS, and REACH certifications are all provided by Xinbo in its ODM and OEM services. They also provide technical support and are committed to ensuring that the machine meets your expectations.

Due to the high quality and after-sales service concerns of Xinbo, it will be very reliable to purchase an Omega Furring Channel Roll Machine from them.

Proper maintenance is essential to ensure the longevity and optimal performance of your Omega Furring Channel Roll Machine:

Regular Cleaning: Clean the machine regularly to remove dust, debris, and metal shavings.

Lubrication: Lubricate all moving parts, including rollers and gears, to ensure smooth operation.

Inspection: Regularly inspect the machine for any signs of wear, damage, or misalignment.

Calibration: Check the machine’s calibration periodically to ensure accurate dimensions and tolerances.

Operator Training: Ensure that the operators are adequately trained in machine operation and its maintenance procedures.

By following this maintenance tips you can extend your machine’s lifecycle and reduce instances of down times.

To choose a proper supplier for the Omega Furring Channel Roll Machine, here are some things that you should focus on:

Quality and Durability: The manufacturing process should have high-quality material and a very strong process itself.

Customize Ability: Ensure that the supplier could customize the machine according to requirements.

Technical Support: A supplier that gives complete technical support and training should be chosen.

Reputation and Experience: Check out their reputation and experience in the industry.

After-sales Services and Warranty: Check the warranty terms and after-sales supporting policies of the supplier.

Production Capability: Check whether the supplier can handle volume and deadline accordingly.

Careful evaluation will help you select a reliable supplier that can meet your needs.

An Omega Furring Channel Roll Machine is a crucial investment for construction companies needing high-quality furring channels. Choosing the right supplier is essential for ensuring efficiency, reliability, and cost-effectiveness. Xinbo stands out as a leading manufacturer, offering a combination of quality, customization, and service. Equipped with a skilled team and guaranteeing customer satisfaction, Xinbo will surely become a trustworthy partner for your needs regarding metal roll-forming. Considering all of the above-mentioned factors, you will make an appropriate choice and buy just the machine needed to fulfill project requirements.

Xinbo is a professional producer of metal shaping and roll-forming machines. Specialized in producing top-class Omega Furring Channel Roll Machines designed to fulfill a wide variety of construction demands. With a commitment to innovation and customer satisfaction, Xinbo offers custom design capabilities ensuring their machines precisely match the requirements of any project. They leverage advanced technology and quality control to provide durable and efficient equipment.

Xinbo provides comprehensive services, including technical support and training, making them a reliable and trusted partner in the roll forming industry. Whether you need high-volume production or unique specifications, Xinbo’s expertise ensures that the final product will meet your most stringent expectations.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→