Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→The efficiency and precision of construction components, especially of crucial parts like furring channels, are significant to the industry. These serve as central pieces in the wall and ceiling assembly framing. Growing demand for dependable and long-lasting furring channels requires top China furring channel machines to produce precision. This country has become a superpower in producing these machines alone because of its innovations in technology. In this article, we will discuss features, benefits, and reasons why the furring channel machines made in China are the favorite amongst the world’s construction professionals.

Furring channels refer to metal-framing components employed during construction processes that provide the perfect level for securing wallboards, plasterboards, or even any other types of paneling against walls and ceilings. Often prepared from galvanized steel, such channels assure adequate distance between material units and aid the structural composition in walls and ceilings. Importantly, such tools are essential in the creation of flush planes or surfaces and, at the same time, allow for strength gains in building design.

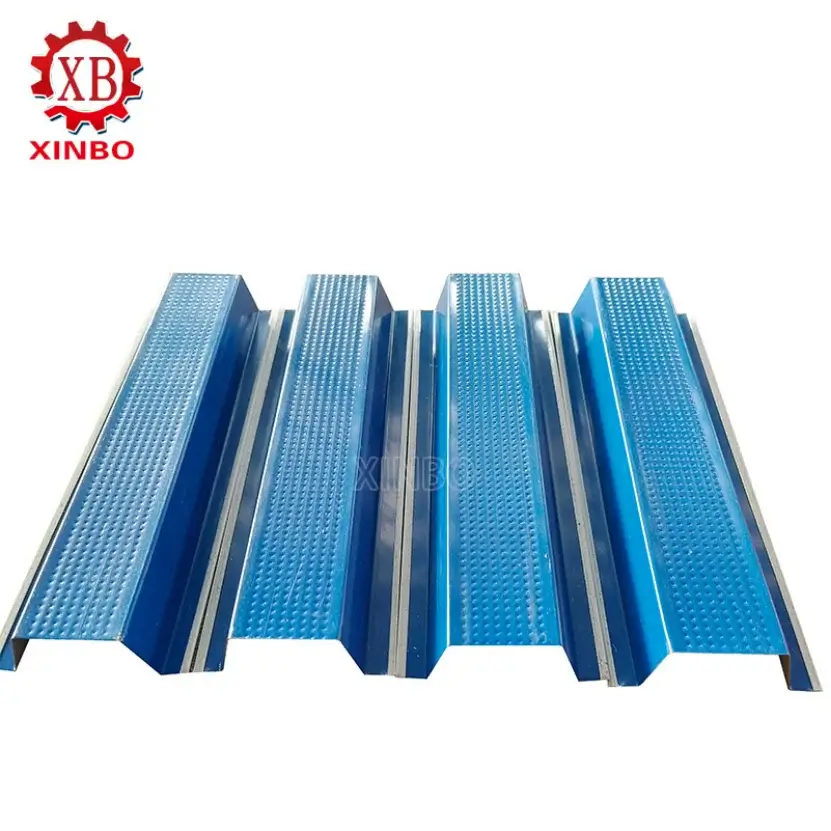

A furring channel machine is an apparatus used for the mass production of very accurate and efficient channels. The roll-forming process of the equipment feeds a metal coil through a sequence of rollers which gradually shape the metal into a specific channel profile. Modern machines are fitted with automated cutting, punching, and stacking units that make the manufacturing process smooth and guarantee output quality and uniformity.

Furring channel machines can be found in different types; each is developed to produce unique channel profiles and sizes. These include:

U-Channel Machines: U-channel machines manufacture U-shaped furring channels, commonly used for supporting suspended ceilings and creating partition walls.

Hat-Channel Machines: These machines produce hat-shaped channels, often used for furring out uneven surfaces and providing additional support for drywall installations.

Stud and Track Machines: Stud and track machines produce both studs (vertical framing members) and tracks (horizontal framing members) for drywall installations. These machines offer versatility in creating complete framing systems.

Double Line Roll Forming Machines: These machines are designed for high-volume production, capable of producing two furring channels simultaneously, significantly increasing output.

When choosing a furring channel machine, several key features should be considered to ensure the machine meets your production needs. The construction of the machine is of utmost importance, and strong steel frames are essential for stability and durability. Precision-machined and adjustable rollers are required for accurate channel profiles, while hydraulic cutting and punching systems ensure clean cuts and precisely placed holes. The control system of the machine should be user-friendly, with real-time feedback and diagnostic capabilities for ease of operation and troubleshooting. Other essential factors include the speed and output capacity of the machine, in addition to safety features such as emergency stop buttons, safety guards, and overload protection to ensure the safety of operators.

There are a number of highly important advantages that use of a furring channel machine compared to doing it manually offers. First of all, automation greatly increases productivity, and a high volume output and fast production times would consequently result in shortening the lead time. Furring channel machines also assure increased accuracy and reliability in the process, with very correct dimensions and repeating hole patterns, making sure there will be no fault in giving that professional look one desires every time. The better utilization of materials and reductions in labor offer greater cost advantages, too. Further, this automation at places enhances safety workplace by minimizing handling heavy material on-site and avoids accidents. Modern furring channel machines lastly facilitate flexibility in production so that manufacturers are able to produce a wide variety of channel sizes and profiles to meet varied project requirements.

China is among the leading manufacturers of machinery that builds high quality at affordable rates. The majority of the leading brands in furring channel machines are based in China and come with great models that introduce efficient features. There is the availability of a good machine if best manufacturers in China who have a history of offering quality products, good support services, as well as innovative solutions to meet the needs of the construction sector are considered.

Xinbo is a leading Chinese manufacturer of furring channel machines that has a high commitment to quality, innovation, and customer satisfaction. They provide a wide variety of machines to suit the various requirements of the construction industry. The furring channel machines of Xinbo are popular because of their excellent durability, advanced technology, and competitive prices. The company is integrated with cutting-edge features, including PLC control systems, servo motor drives, and hydraulic cutting and punching units to provide high performance to its customers.

Xinbo furring channel machines are well-known for their superior quality and strength. The machines are built from the best quality material and are designed for a long life of service in rigorous production conditions. The company also adopts the use of advanced technology in its machines; these include PLC control systems and hydraulic cutting units to ensure the operation is precise and efficient. Thirdly, customer support provided at Xinbo by way of consultation services, installation guidance, technical support as well as spare parts available. In addition, the cost-effective strategy has helped the company to reach its machines to all levels of businesses starting from small-scale businessman up to large construction companies.

China has managed to position itself at the forefront of high-quality, precision-driven furring channel machines. Due to the high demand for building components that will last, the world’s construction companies have relied on Chinese manufacturers, such as Xinbo, to supply their businesses. Through investment in a furring channel machine from a well-known Chinese manufacturer, a company will be able to improve production capacity, ensure the quality of its work, and thus enjoy the advantage of market leadership in this expanding construction sector.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→