Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→In the modern world of fast-paced manufacturing, the Automatic Aluminum Metal LED Channel Mounting Clip Roll Forming Machines have made a huge impact in the industry. The machines play a key role in converting raw material into precision-made clips that are used in various industries, mainly the rapidly expanding LED industry.

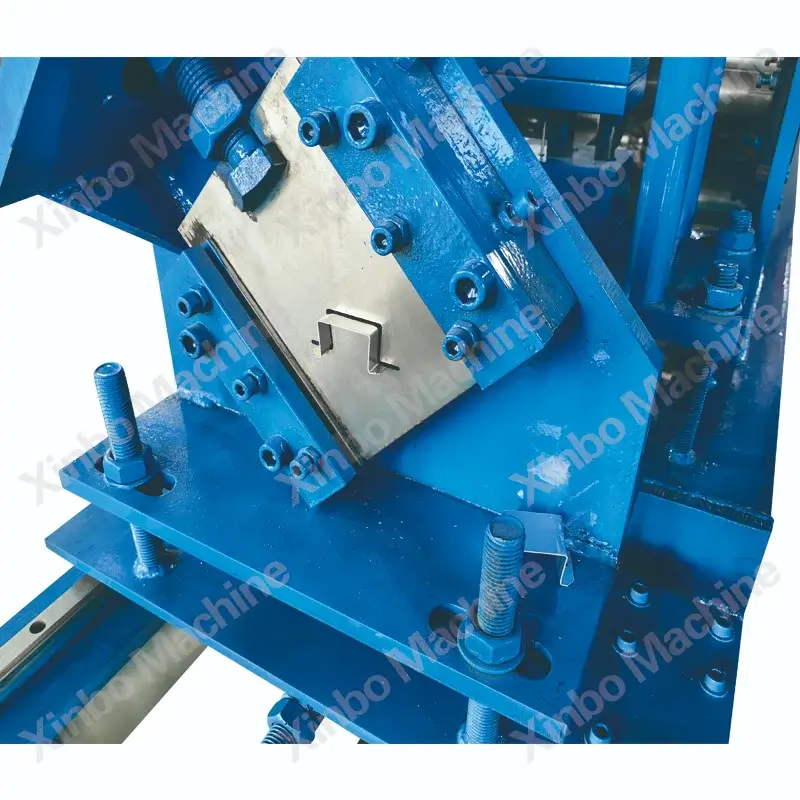

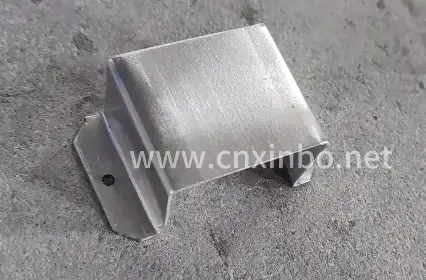

Roll forming machines are industrial giants that roll metal sheets continuously into cross-sectional shapes of choice. For Aluminum Metal LED Channel Mounting Clip Roll Forming Machines, they produce clips with precise geometries. These clips find application in firmly fixing LED channels for proper installation and stability in lighting fixtures.

Aluminum is a good material for these clips due to its light weight, corrosion resistance, and good electrical conductivity. In the context of LEDs, where power efficiency and longevity are paramount, these clips provide a proven solution. They hold LED channels firmly, allowing effective heat dissipation, which is important for the longevity of LED lamps.

The need for these machines is increasing. As more people use LED lights in homes, offices, and industries, the need for better-quality mounting clips has increased a lot. The companies are constantly searching for machines that can produce clips at a higher speed, with greater accuracy, to meet the increasing demand in the market.

Xinbo Automatic Aluminum Metal LED Channel Mounting Clip Roll Forming Machines are engineered to achieve a close tolerance control. Clip forming is of very high accuracy in such a way that each clip exactly comes with precisely needed dimensions. That accuracy provides a tight fit when these clips are installed for LED channel fixtures.

The machines are designed to deliver consistent quality output. Every clip produced has the same high-quality finish, whether it is the first or the thousandth. This consistency reduces manual inspection and rework, which saves time and resources.

Xinbo’s machine is also equipped with automatic feeding and unloading systems. Raw aluminum sheets are fed into the machine smoothly, and the manufactured clips are unloaded automatically without manual intervention. Not only does this speed up the production process, but it also prevents the chance of human error.

These machines further boast high output speeds. They are capable of generating enormous volumes of clips within minutes, resulting in productivity to go through the roof. These high-speed levels are required in order to enable manufacturers to fulfill stringent deadlines and colossal orders.

Xinbo machines employ rollers made of high-quality materials. The materials are chosen based on their durability and ability to withstand the stresses of high pressure and friction of the roll-forming process. This ensures that the rollers are durable, reducing the need for frequent replacement.

The geometric construction of the rollers is specifically tailored to perfect clip formation. Care is taken to construct the rollers so that the rollers can flex the aluminum sheets easily and precisely into the intended clip shape. Intelligent Control Systems

The Programmable Logic Controllers (PLC) are integrated into the machines. These controllers allow the whole roll-forming process to be managed with high accuracy. Certain parameters, for instance, the speed of the machine, pressure used, and dimensions of the clip, can be programmed by operators to ensure accurate and consistent production.

Human-Machine Interface (HMI) makes it simple to operate the machine. It is user-friendly and through it, operators are able to see the process of manufacturing, set parameters, and receive instant feedback. The simplicity reduces the time taken to train new operators.

Because of the high level of automation, the machines do not require much human intervention. This reduces the cost of labor as less labor is needed to operate the machines.

The precision of the machines ensures minimal wastage of material. The precise clip forming ensures less loss of aluminum while producing the clips, hence reduced material cost.

The high quality construction and precision forming process ensure clips that have improved durability. Such clips have the capability of enduring severe weather conditions and mechanical loads and therefore are suited for long-term applications in LED fittings.

Xinbo machines produce clips with a desirable finish. The smooth and uniform face of the clips not only looks good but also improves the overall look of the LED fixtures.

The clips produced by the machines are the best mounting solution for LED channels. They provide a secure and fixed fit, which ensures that the LED channels stay securely fastened.

The clips are designed to be universal in their use across different LED fixture designs. Ranging from a simple home light to an advanced industrial lighting setup, the clips can be efficiently used.

The use of these machines facilitates the manufacturing process for LED makers to be more streamlined. The automated and efficient production of clips leads to faster turnaround time, from raw material to finished product.

The advanced technology in such machinery also stimulates new technologies in adjacent industries. It may, for example, stimulate new designs in LED lighting machinery or create more performing aluminum alloys.

When selecting the machine, manufacturers have to consider their requirements in terms of capacity. Xinbo has equipped machines differently so that customers can choose one based on their specific requirements.

The machines are highly flexible and can produce clips of different sizes. This is important because it allows manufacturers to meet the different demands of the market.

Xinbo maintains quality maintenance and repair services. Their professionals are always ready to keep the machines in proper working order. Regular maintenance can extend the lifespan of the machines and prevent costly breakdowns.

Spare parts for Xinbo’s machines are readily available. This ensures that when a component fails, the machine can be fixed in a matter of minutes, hence saving on downtime.

Xinbo is a leading producer in the industry. In addition to the Automatic Aluminum Metal LED Channel Mounting Clip Roll Forming Machines, they also produce a wide range of products. Their customized Clip Panel Roll Forming Machines for various applications are in demand. Their equipment is utilized to meet particular requirements of special industries, such as providing particular solutions. Xinbo manufactures other products like the Xinbo Automatic Aluminum Metal LED Channel Mounting Clip Roll Forming Machines. Its emphasis on quality, innovation, and specialized solutions renders them a manufacturer’s favorite globally. Whether it is small-scale production or large-scale industry, Xinbo has the right products and services to meet the requirements.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→