The Role of Roll Forming Machine Manufacturers in Construction

Exploring the Basics of Roll Forming Machines

Understanding Roll Forming Technology

Roll forming technology is a versatile and efficient method used to shape metal sheets into desired profiles and forms. The process involves feeding a metal strip through consecutive sets of rolls, gradually bending the material to achieve the desired cross-sectional profile. This continuous shaping process allows for the production of long lengths of uniform components, making roll forming an ideal choice for manufacturing construction materials and structural components.

The Process of Roll Forming

The roll forming process begins with a coil of metal that is fed into the first set of rolls, where it is gradually shaped as it moves through each subsequent set. The gradual bending and forming of the material result in a final product with consistent cross-sectional dimensions along its length. This method offers precision and repeatability, ensuring uniformity in the manufactured components.

Types of Roll Forming Machines

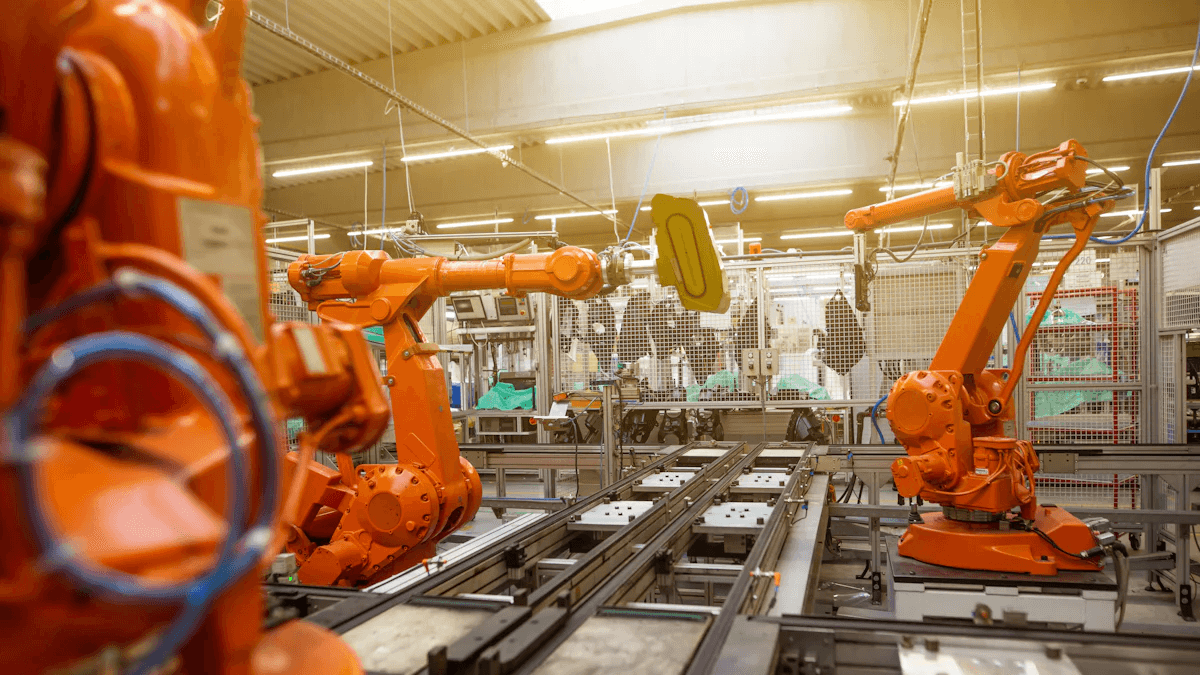

There are various types of roll forming machines designed to accommodate different production needs. These machines can range from standard configurations to custom-built systems tailored to specific requirements. Some common types include duplex roll forming machines, multi-profile roll formers, and portable roll forming equipment. Each type serves distinct purposes and offers unique capabilities for diverse manufacturing applications.

Key Components of Roll Forming Machines

Roll forming machines consist of several key components that play crucial roles in the manufacturing process.

The Role of Mated Rolls

Mated rolls are essential components within a roll forming machine, as they directly shape the metal strip by applying incremental changes at each stage. These rolls work in pairs, exerting controlled pressure to bend and form the material according to the desired profile.

Importance of Machine Calibration

Machine calibration is vital for ensuring precise and accurate production outcomes. Proper calibration involves adjusting various parameters such as roll positions, material feed rates, and cutting mechanisms to maintain consistency in product dimensions and quality.

The Critical Role of Roll Forming Machine Manufacturers in Construction

Roll forming machine manufacturers play a critical role in supplying the construction industry with essential tools that are tailored to meet specific project requirements. Their ability to provide custom solutions and ensure reliability and precision has a significant impact on construction efficiency and the overall economic landscape.

Supplying the Construction Industry with Essential Tools

Custom Solutions for Construction Needs

Roll forming machine manufacturers, such as Xinbo Machine Making, understand the diverse needs of construction projects and offer custom solutions to address specific challenges. Each project is custom designed and engineered, allowing customers to work with available, equally engineered products that provide solutions for various applications. For instance, these manufacturers supply standard sheet piling, H-pile, or pipe pile products that are interchangeable, showcasing their commitment to meeting the unique demands of construction projects. Additionally, they continuously seek opportunities to fabricate new custom products that are project-specific, demonstrating their dedication to innovation and problem-solving within the construction industry.

Ensuring Reliability and Precision

The products provided by roll forming machine manufacturers are not only customized but also ensure reliability and precision in construction applications. Whether it’s custom pile caps or fabricated waler systems, these essential tools are engineered to meet stringent quality standards and performance requirements. By delivering reliable and precise solutions, manufacturers contribute to the seamless execution of construction projects while maintaining high levels of safety and structural integrity.

The Economic Impact of Roll Forming Machine Manufacturers

Contribution to the Global Market

The contributions of roll forming machine manufacturers extend beyond individual construction projects; they have a substantial impact on the global market. By providing essential tools for construction applications worldwide, these manufacturers contribute to the growth and stability of the global construction industry. Their ability to offer custom solutions ensures that diverse regional requirements can be met effectively, further solidifying their influence on a global scale.

Supporting the Growth of Construction Projects

Roll forming machine manufacturers support the growth of construction projects by enabling efficient production processes and enhancing project timelines. Through their innovative solutions and reliable equipment, they empower construction companies to take on complex projects with confidence. This support directly translates into accelerated project completion times, cost savings, and improved overall efficiency within the construction sector.

Innovations and Advancements: How Manufacturers Are Shaping the Future

In the ever-evolving landscape of construction technology, roll forming machine manufacturers are spearheading innovations and advancements that are reshaping the future of the industry. By introducing portable and compact solutions, as well as focusing on customization and continuous improvement, these manufacturers are revolutionizing the way construction materials are fabricated and utilized.

Introducing Portable and Compact Solutions

Benefits of On-Site Roll Forming

One of the notable advancements in roll forming technology is the introduction of portable and compact roll forming machines. These innovative solutions have transformed on-site construction processes by enabling the seamless fabrication of custom profiles directly at the project location. The benefits of on-site roll forming are multifaceted, ranging from cost savings to enhanced efficiency. Contractors can now eliminate material waste by forming panels to exact lengths, ensuring that only the necessary amount of material is used for each project. This not only reduces material costs but also minimizes environmental impact by optimizing resource utilization.

Customization and Continuous Improvement

Meeting the Demands for Complex Profiles

Roll forming machine manufacturers are continuously enhancing their capabilities to meet the increasing demands for complex profiles in construction applications. Technical improvements, such as automated servo-electric roll forming machines, have propelled the industry forward by offering better performance and precision in shaping metal sheets into straight formed shapes. This level of customization allows manufacturers to cater to diverse needs across industries, including automotive, aviation, oil & gas, and construction.

The Importance of Skilled Operators

Amidst these technological advancements, it’s crucial to emphasize the importance of skilled operators in maximizing the potential of roll forming machines. While advanced equipment plays a pivotal role in shaping metal sheets with precision, skilled operators bring expertise in setting up and operating these machines effectively. Their ability to interpret technical specifications, monitor production processes, and troubleshoot potential issues ensures that customized profiles are manufactured with utmost accuracy.

Roll forming machine manufacturers continue to drive innovation through their commitment to customization and continuous improvement. By embracing portable solutions and prioritizing skilled operators, they are not only shaping the future of construction but also revolutionizing how complex profiles are fabricated on-site.

Xinbo Machine Making Co. Ltd, established in China since 2014, is a renowned manufacturer of roll forming machines. The company is committed to providing quality assurance through a team of professional designers, producers, and workers. Xinbo’s roll forming machines are designed with innovative technology to cater to the needs of customers globally, particularly in Europe, the UK, and Canada.

The Impact of Roll Forming Machines on Modern Construction

Versatility in Construction Applications

Roll forming machines have revolutionized modern construction by offering unparalleled versatility in the production of various components and materials. From metal channels to wall panels, these machines have become indispensable in shaping a wide range of products that form the backbone of contemporary construction projects.

The utilization of roll forming machines has significantly expanded the possibilities for creating complex profiles required in modern construction projects. Unlike traditional construction methods, modern roll forming machine applications have streamlined metal forming processes and ensured a high level of security. This technological advancement has not only simplified manufacturing processes but also elevated the precision and quality standards within the construction industry.

The Future of Roll Forming in Construction

As technology continues to advance, the future of roll forming in construction looks promising, with several predictions and trends shaping the industry landscape. One prominent trend is the increasing emphasis on sustainable practices within roll forming processes. Manufacturers are exploring eco-friendly materials and energy-efficient production methods to align with global sustainability initiatives. This shift towards sustainable practices reflects a commitment to environmental responsibility while meeting the evolving demands of the construction sector.

Furthermore, predictions indicate a continued market expansion driven by ongoing technological advancements in roll forming machines. These advancements are expected to further enhance efficiency, accuracy, and customization capabilities, positioning roll forming as a pivotal technology in modern construction practices.

Final Thoughts

Embracing the Future with Roll Forming Machine Manufacturers

Roll forming machine manufacturers have been at the forefront of driving technological advancements and shaping the future of the metal fabrication industry. The continuous evolution of roll forming machines has paved the way for innovative solutions that cater to diverse manufacturing needs, particularly in the construction sector.

The Continuous Evolution of the Industry

The global market size for roll forming machines is projected to expand significantly, indicating a promising trajectory for the industry. The integration of advanced technologies, such as automated servo-electric systems and intelligent control units, reflects a commitment to continuous improvement and innovation within the industry.

Roll forming machines are designed to make sheet metal into straight formed shapes through a series of hardened steel rollers. This method allows for rapid shaping and high-volume production, meeting the demands of various industries including automotive, construction, aviation, and oil & gas. The rapid growth of these end-use industries has been a key driver for market expansion.

Preparing for the Next Generation of Construction

As roll forming machine manufacturers focus on developing products with enhanced performance and efficiency, they are effectively preparing for the next generation of construction practices. By reducing manual labor and increasing productivity, these advanced technologies are set to revolutionize how construction materials are fabricated and utilized. Furthermore, their ability to streamline metal forming processes while maintaining high levels of safety aligns with the evolving needs of modern construction projects.

The future holds great promise for roll forming machines as they continue to drive market expansion through technological advancements. As manufacturers embrace sustainable practices and prioritize customization capabilities, they are not only shaping the future of construction but also revolutionizing how complex profiles are fabricated on-site.

In conclusion, embracing the future with roll forming machine manufacturers entails recognizing their pivotal role in driving industry evolution and preparing for a new era of construction practices that prioritize efficiency, precision, and sustainability.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia