Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

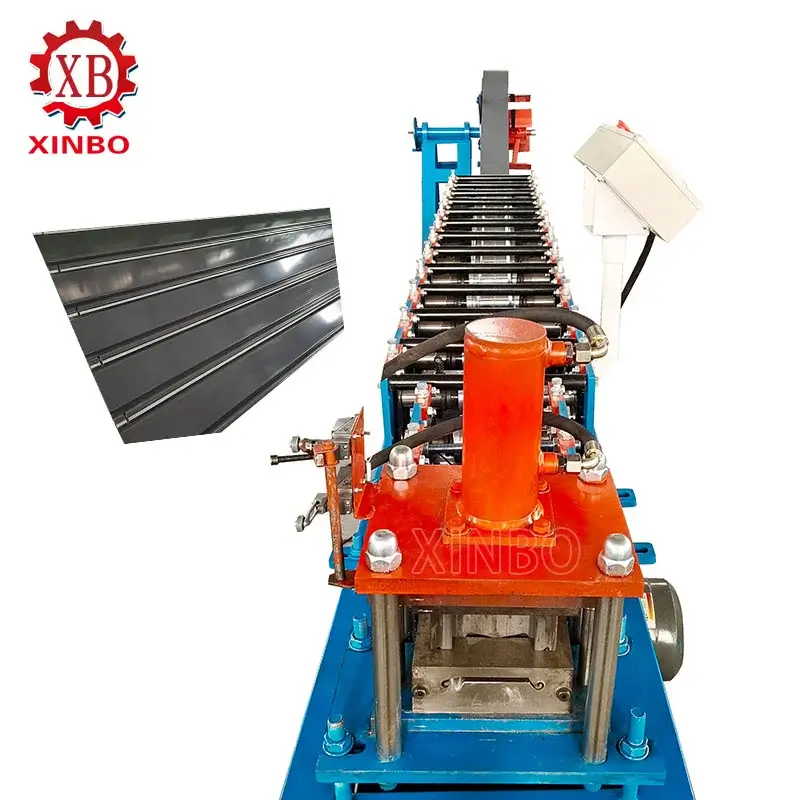

VIEW MORE→For businesses associated with the security and building industries, shutter door panels play a vital part in durable, reliable, and secure solutions. As a wholesale supplier or manufacturer of roller shutter doors, the equipment on which production relies for these sorts of panels is just as critical. The key to efficiency and quality is in the type of machinery chosen, namely shutter door panel machines.

These machines are designed to produce metal slats from flat coils, further interlocked to form the strong and secure panels used in the roller shutter. From manufacturing high-volume quantities for commercial buildings to customized designs for residential projects, the right shutter door panel machine will optimize production by reducing costs and guaranteeing consistency in quality.

In this business-to-business guide, we’ll explore the key features, benefits, and applications of shutter door panel machines. We’ll also showcase Xinbo, a leading manufacturer in roll-forming and metal shaping machinery, known for its cutting-edge Embossing Roller Shutter Door Panel Machine, and why it should be your go-to partner in shutter door production.

The shutter door panel machine is an advanced-type roll-forming machine employed solely in the manufacturing of metal slats for roller shutter doors. These machines take in flat metal coils, commonly prepared by galvanized steel or another similar hard metal, and modify these metal blanks into slats with all identical dimensions. After processing, slats are fitted together in interlocking joints to make up a shutter door panel. This manufactured panel provides great functionality as well as top security along with outstanding lookiness for good taste.

The success of manufacturing relies on the machine’s ability to produce quality slats consistently with precision, speed, and flexibility, thus giving each door panel the desired standards it needs in terms of durability, performance, and design.

Wholesale suppliers and manufacturers are supposed to understand the potential of a shutter door panel machine to further their production processes. Here are the basic features that distinguish modern shutter door panel machines from traditional ones:

Shutter door panels call for precision to ensure smooth interlocking slats. The modern machinery is equipped with advanced technologies like PLC control, hydraulic profile cutting, and encoder-based length measurement systems. These features ensure that every slat is made with consistent dimensions, which is so vital for smooth operation and secure door installation.

By investing in such a machine that gives them precision slat production, businesses can avoid waste, defects, and ensure that every panel made meets the required safety.

Every project has unique requirements, whether it is in terms of size, thickness, or even profile design. An excellent shutter door panel machine avails wide customization, including: ·Input and Formed Width: Can be adjusted to conform to particular design and dimensional requirements.

Material Thickness: With the ability to process materials up to 1.0mm or more in thickness, it also presents flexibility for customized thickness applications.

Embossing Capabilities: Certain products, such as the Embossing Roller Shutter Door Panel Machine by Xinbo, can add embossed patterns to increase the aesthetic of the final product.

Manufacturers can easily produce doors serving different purposes, whether used in industrial buildings, warehouses, or residential use, all produced on a single machine instead of multiple machines.

The modern Shutter Door Panel Machine is designed for automatic operation, minimizing the need for manual labor. Touchscreen controls and PLC integration have made the machines very friendly to the operators, who can handle the production lines with efficiency and quality. With less human interference, these machines can run longer cycles and produce more volumes at reduced costs.

High-speed production capability is important in meeting the demands of businesses for large orders or orders that have to meet very tight deadlines. Most shutter door panel machines can attain production speeds of up to 15 meters per minute, thus enabling manufacturers to make large volumes in relatively short periods of time.

This high-speed capability makes these machines ideal for commercial and industrial applications where volume production is a priority, thus ensuring that businesses can keep up with the demands of the market and increase their output.

A shutter door panel machine is an investment that pays off over time. First of all, the durability is important because it will see continuous use in a hard manufacturing environment. High-quality shutter door panel machines are designed with frames made of high-strength steel and also heavy-duty rollers, limiting wear and tear to negligible levels over a period.

Additionally, these machines are designed for low maintenance with easily accessible parts and systems, simple to repair or replace. Routine checks and preventive maintenance can extend the lifespan of the equipment, ensuring years of continued reliability.

Shutter door panel machines are applied in a number of industries because of their versatility and the security, quality of the product they produce. Some of the common applications are as follows:

Roller shutters are an effective security solution in commercial and industrial settings for storefronts, warehouses, factories, and other commercial properties. The panels produced by shutter door panel machines are essential for making these robust, secure doors.

Shutter doors are also finding their application in residential usages, especially for garages, windows, and security entrances. With customizable designs, they can add both security and aesthetic value to homes.

In self-storage facilities, shutter doors are appropriate for individual units. The slats produced are durable and provide extra security with ease of access.

In the automotive industry, shutter doors are used to protect the service area, garage, and even storage for spare parts. These doors have to put up with heavy use and still retain their security; thus, they are a very good candidate for high-quality shutter door panel machines.

Xinbo has designed and manufactured high-quality roll-forming and metal shaping machines for over a decade. As one of the leading suppliers in this line of business, innovative and reliable equipment such as the Embossing Roller Shutter Door Panel Machine is attributed to Xinbo.

Below is an overview of the machine’s key benefits and technical specifications:

|

Feature |

Description |

|

Processing Material |

GI coils |

|

Input Width |

Customized according to need |

|

Formed Width |

As per drawings or customer specifications |

|

Processing Thickness |

Standard: max 1.0mm, customized options |

|

Frame Style |

Square pipe welded |

|

Material of Rollers |

45# steel, heat-treated and hard chromed |

|

Diameter of Shaft |

50mm |

|

Production Speed |

Standard: 0–15m/min, customizable |

|

Roller Driven |

Decelerating Motor + China Transmission |

|

Cutting Model |

Hydraulic Profile Cutting |

|

Length Measurement |

Encoder |

|

Control Style |

PLC |

|

Operation Model |

Button + Touch Screen |

|

Total Power |

4+4KW, customizable |

|

Voltage |

380V, 50Hz, 3-phase or customized |

For inquiries, contact Xinbo, the manufacturer of the Embossing Roller Shutter Door Panel Machine:

-Email: serena@cnxinbo.net

-Phone: +8615032075911

Customized Solutions: The company provides custom machines according to each customer’s specifications, from slat thickness to profile design.

Advanced Technology: Xinbo’s machines employ the latest technologies, including PLC control, hydraulic cutting, and high-speed production.

Competitive Pricing: With an in-house manufacturing facility, Xinbo can offer competitive pricing to assist businesses in improving profitability.

Global Support: Xinbo offers remarkable customer service and global support to make sure timely assistance is provided to companies all over the world.

Ready to upgrade your production? Contact Xinbo today for more details about their shutter door panel machines and how they can make your manufacturing process smoother:

-Email: serena@cnxinbo.net

-Phone/WhatsApp: +8618713731132

This can be concluded by stating that high-quality shutter door panel machine investments will help the growth of an enterprise through staying competitive and producing quality products efficiently. In case you seek the latest in roll-forming technology and precision in manufacturing to meet diverse customers, this could be offered through the Embossing Roller Shutter Door Panel Machine of Xinbo.

Make the smart choice today and let your production take on the higher notch with Xinbo!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→