Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

High-performance curving panel machines have revolutionized the way industries approach the fabrication of curved structures. These specialized machines offer enhanced precision, efficiency, and versatility in processing various types of materials, which is crucial for achieving optimal results in manufacturing. Understanding the operational advantages and features of these machines can enable companies to streamline their production processes significantly.

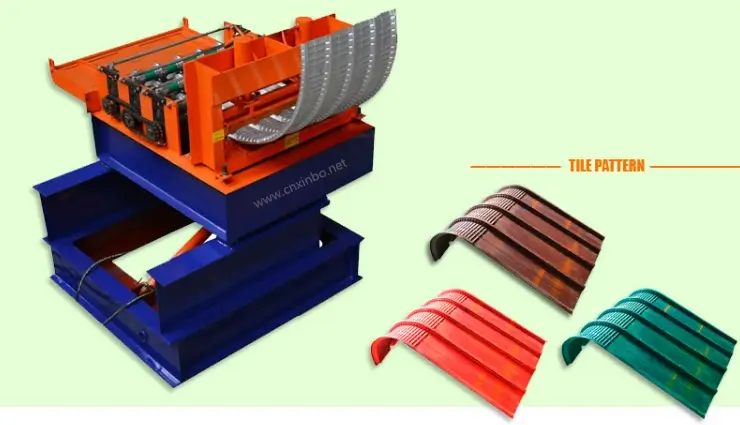

Curving panel machines are advanced industrial devices designed to create curved forms from flat materials, such as metal sheets, wood, plastic, and composites. These machines utilize various techniques, including bending, rolling, and shaping, to produce precise curves and arcs. Curving panel machines are widely used in sectors such as construction, furniture manufacturing, automotive, and aerospace, where precision and aesthetic appeal are paramount.

The implementation of high-performance curving panel machines leads to numerous benefits. Firstly, they enhance production speed, allowing manufacturers to meet tight deadlines without sacrificing quality. Secondly, these machines enable a higher level of precision, which is crucial for applications that demand exact specifications. Additionally, with increased efficiency, companies can reduce waste material and lower their operational costs, leading to improved profitability over time.

XINBO MACHINE MAKING CO. LTD has established itself as a leader in the development and manufacture of curving panel machines. The company focuses on engineering solutions that optimize performance and productivity in the manufacturing sector. By prioritizing innovation and research, XINBO continues to advance its technology to meet the evolving demands of the industry, making its machines indispensable tools for modern manufacturers.

Over the years, XINBO has reached several key milestones in curving machine technology. The company has successfully launched numerous models that cater to different industry needs, demonstrating its commitment to continuous improvement and excellence. Their reputation in the marketplace is bolstered by a portfolio of satisfied clients and significant participation in international trade shows, showcasing their innovative products and comprehensive solutions.

XINBO’s curving panel machines are engineered with a robust design that ensures durability and reliability under harsh operating conditions. The materials used in construction are selected specifically to withstand high levels of stress while maintaining precision performance. This quality build contributes to the longevity of the machines, reducing maintenance costs and downtime, thereby optimizing operational efficiency in workshops.

The advanced automation capabilities of XINBO’s machines significantly enhance their ease of use and efficiency. Equipped with cutting-edge technology, these machines can perform complex tasks with minimal human intervention, allowing operators to focus on more critical aspects of production. Automated features, such as computer numerical control (CNC), facilitate precise control over the shaping process, resulting in high-quality finishes and reduced errors.

XINBO’s curving panel machines are highly versatile, accommodating a wide range of panel types and materials. Whether it’s metal, wood, or composite materials, the machines can be configured for various tasks. This adaptability allows manufacturers to switch between projects seamlessly, catering to diverse customer requirements without investing in multiple machines.

The applications of XINBO’s curving panel machines span many industries. From producing architectural elements such as curved facades and decorative features to crafting parts for vehicles, the versatility of the machines enhances their utility across different sectors. This wide-ranging applicability ensures that manufacturers can rely on a single comprehensive solution for multiple production needs.

One of the most significant advantages of using XINBO’s curving panel machines is their ability to reduce production time. Efficient processing capabilities allow for faster setup and operation, which significantly cuts down the overall time taken to complete projects. As a result, businesses can take on more work and meet deadlines with ease, leading to increased customer satisfaction.

With a focus on precision engineering, XINBO machines deliver exceptional quality in every curved panel produced. Advanced automated processes minimize the risk of human error, ensuring that each component meets stringent quality standards. This high level of accuracy not only enhances the final product’s performance but also builds trust with clients who rely on consistency and reliability.

Incorporating XINBO’s high-performance curving panel machines into a manufacturing process ultimately leads to lower operational costs. With increased efficiency, reduced waste, and improved precision, companies can optimize their resource allocation and streamline their production workflows. The investment in such advanced technology pays off in the long run, as manufacturers can reduce material costs and labor expenses while increasing output.

Curving panel machines are pivotal in the architectural realm, where creative designs frequently necessitate uniquely shaped structures. They facilitate the production of curved facades, arches, and decorative elements that significantly enhance architectural aesthetics. The precision offered by these machines allows for the consistent replication of designs, ensuring architectural integrity while providing flexibility in design choices. Projects ranging from modern skyscrapers to intricate residential build-outs showcase the capability of curving equipment to bring imaginative concepts to life, thereby contributing to innovations in architecture and structural engineering.

In the automotive industry, curving panel machines play a critical role in the manufacturing of components that require curved shapes for aerodynamics and aesthetics. The machines allow for the efficient production of body panels, chassis components, and internal fittings, which must adhere to stringent performance and safety standards. The capability to produce complex curves with high precision ensures optimal fitment and performance during automobile assembly. The adoption of curving technology has enabled manufacturers to experiment with design enhancements that improve vehicle efficiency, resulting in a competitive edge within the market.

Beyond architecture and automotive, curving panel machines find applications in various industrial sectors including aerospace, furniture production, and shipbuilding. In aerospace, these machines are instrumental in creating lightweight, curved components that are essential for aircraft performance and fuel efficiency. Similarly, in furniture manufacturing, curving panel technology allows for the crafting of ergonomically designed furniture pieces that offer both comfort and style. The ability to adapt to different materials and production demands makes curving panel machines indispensable in an array of industries, emphasizing their versatility and importance in contemporary manufacturing.

Selecting the appropriate curving panel machine starts with a thorough assessment of operational requirements. Companies should consider the types of materials they will process as well as the complexity of the designs they aim to create. Additionally, evaluating production volume requirements helps in determining the machine’s output capacity, ensuring that it aligns with future growth projections. Companies should also take into account the existing infrastructure, as the machine’s size and power requirements must be compatible with the production environment.

One of the foremost considerations when choosing a curving panel machine is material compatibility. Different machines are designed to work with specific materials, such as metals, plastics, or wood. Understanding the types of materials that will be processed can significantly impact the selection process. Companies must ensure that the chosen machine can handle the variations in thickness, strength, and flexibility of their materials while still achieving the desired curvature and finish.

Output capacity is another critical factor influencing the choice of a curving panel machine. Manufacturers need to evaluate their production goals and select a machine that can meet or exceed these targets without compromising quality. This entails looking into the machine’s speed, the maximum size of the panels it can process, and its operational efficiency. A higher output capacity can lead to decreased lead times and improved turnaround rates, ultimately enhancing customer satisfaction.

Considering maintenance needs is essential in the machine selection process. Curving panel machines require regular upkeep to ensure optimal performance and longevity. A machine with easy access to critical components and readily available replacement parts can significantly reduce maintenance downtime and costs. It is advisable to choose manufacturers that provide comprehensive support and maintenance services, ensuring that the machine remains functional and efficient throughout its operational life.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→