Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→1.Processing flowchart

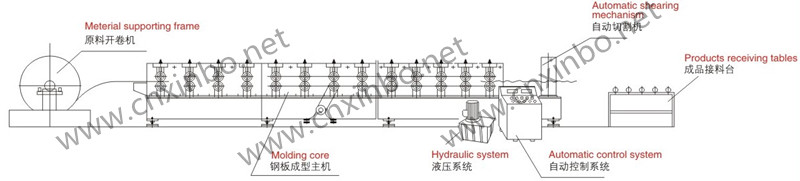

Manual Uncoiler — Entry Beach—Roll Forming Machine—Automatic Shearing Mechanism-Computer Control Cabinet— Run-out Tables

2.Main Parameter of Roll Forming Machine:

|

Suitable to Process |

Color steel sheet ; Galvanized sheet ; Iron sheet; Aluminum sheet |

||

|

Width of raw material |

customized |

||

|

Rollers |

customized |

||

|

Dimensions |

About 6500*1550*1200mm |

||

|

Power |

3+3kw |

||

|

Thickness of sheet |

0.3-0.8mm as usual; |

||

|

Material of cutting blade |

Cr12 |

||

|

Diameter of the roller |

customized |

||

|

Voltage |

380V, 50Hz, 3 phrases; or as customer needing |

||

|

weight |

About 3T |

||

|

Productivity |

10-15m/min |

||

|

Control system |

Automatically controlled by computer |

||

|

Detailed Images |

|||

|

Uncoiler

|

It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by automatic. Loading capacity:5T Inner diameter: 450-508mm

|

||

|

Entry Beach

|

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

||

|

Rollers

|

In order to get high quality product, our machine adopts welded steel frame structure, AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating. Roller chrome coated thickness: 0.05 mm. |

||

|

Computer Control Cabinet

|

It adopts PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

|

||

|

Hydraulic Station

|

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function.The system includes a set of hydraulic tank, a set of a Gear Pump, two hydraulic pipes .and two sets of Solenoid Valves. Power of The Pump:4kw Hydraulic oil :40# |

||

|

Shearing Mechanism

|

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12 Components:It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

||

3.Brief introduction

This machine is mainly used to produce various roof panels and hidden roof panels. It is a substitute for the traditional roof panel tile pressing machine. The whole machine is controlled by imported PLC, and can be used with other tile pressing machine supporting equipment to achieve all-weather continuous production.

Fully automatic computer control and automatic production equipment are adopted. The machine does not need too much manual participation. The workers input the desired sheet data in the computer controller, press one key to start, and the machine will automatically produce. After reaching the set length of the sheet, the machine will automatically cut, with accurate cutting size and small error range. After the cutting is completed, the workers can sort out the finished sheet. The cut section shall be neat for construction and installation.

The profiled plate produced has solved the roof leakage problem of conventional series of profiled plates. The connection of profiled plates has broken the convention of traditional roof connection with bolts. The installation method adopts 180 degree lock bite to make the roof waterproof effect more perfect.

4.Final product display

This machine has a variety of specifications. If you are interested, you can call+86-18931703260 or send the demand drawings to my mailbox serena@cnxinbo.net

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→