Solving the Purlin Material Dilemma: What’s the Best Choice?

Understanding Purlins and Their Importance in Construction

What Are Purlins?

Purlins are horizontal structural elements utilized within roofing systems. They serve a vital function in supporting the roof deck and facilitating load transfer to the main building framework. Their fundamental role is to enhance stability and bolster support for the entire roofing structure, thereby ensuring resilience against diverse loads and environmental conditions.

Definition and Function

Purlins are commonly made of wood, steel, or aluminum and are installed parallel to the ridge line of a roof. They serve as a means to support the rafters or trusses and distribute the weight of the roof covering material.

The Role in Roof Structure

In the context of a roof structure, purlins act as an essential link between the roofing material and the main building frame. They provide lateral support to prevent buckling of rafters or trusses, contributing to overall structural integrity.

Why Purlins Matter

Purlins are integral to the stability and longevity of a building’s roofing system. Their significance lies in their ability to effectively distribute loads and provide essential support for various roofing materials.

Load Distribution and Support

One of the key reasons why purlins matter is their role in evenly distributing loads across the rafters or trusses. This ensures that the weight of the roof is uniformly supported, minimizing stress on individual components and enhancing structural durability.

Impact on Building Longevity

The presence of well-designed purlin systems can significantly impact a building’s longevity by providing adequate support for the roof structure. Properly installed purlins contribute to reducing potential issues such as sagging, which can lead to water ponding and premature deterioration of roofing materials.

Exploring Purlin Materials: Pros and Cons

When it comes to selecting the most suitable purlin material for a construction project, it’s essential to weigh the advantages and disadvantages of each option. The choice of purlin material can significantly impact the structural integrity, longevity, and overall performance of the roofing system. Let’s explore the pros and cons of wood, steel, and aluminum purlins.

Wood Purlins

Wood has been a traditional choice for purlins in construction due to its natural insulation properties and aesthetic appeal.

Advantages: Natural Insulation and Aesthetics

·Natural Insulation: Wood possesses inherent insulating properties, which can contribute to maintaining comfortable indoor temperatures while reducing energy consumption.

·Aesthetics: Wood purlins lend a rustic charm and warmth to the overall architectural design, adding visual appeal to the structure.

Disadvantages: Susceptibility to Rot and Pests

·Susceptibility to Rot: Without proper treatment and maintenance, wood purlins are prone to rot when exposed to moisture over time.

·Pest Vulnerability: Insects and pests can cause damage to wooden purlins if preventive measures are not implemented effectively.

Steel Purlins

Steel is widely recognized for its strength, durability, and resistance to corrosion, making it a popular choice for purlin material in modern construction projects.

Advantages: Durability and Resistance to Corrosion

·Durability: Steel purlins exhibit exceptional strength and resilience, ensuring long-term structural stability.

·Resistance to Corrosion: Galvanized steel grade 50 is commonly used in construction due to its ability to withstand corrosion even in challenging environmental conditions.

Disadvantages: Cost and Conductivity

·Cost Consideration: The initial investment for steel purlins may be higher compared to other materials; however, their longevity often offsets this upfront cost.

·Conductivity: Steel is a good conductor of heat and electricity, which may require additional insulation measures in certain applications.

Aluminum Purlins

Aluminum offers unique advantages as a purlin material, particularly in applications where lightweight yet durable support is required.

Advantages: Lightweight and Rust Resistance

·Lightweight Nature: Aluminum purlins are significantly lighter than steel counterparts, simplifying handling during installation.

·Rust Resistance: Aluminum exhibits natural resistance to rust or corrosion, making it suitable for use in humid or coastal environments.

Disadvantages: Strength Compared to Steel

·Strength Comparison: While aluminum is lightweight, it may not offer the same level of structural strength as steel in certain load-bearing scenarios. Careful consideration of load requirements is essential when opting for aluminum purlins.

In evaluating these materials’ pros and cons, builders can make informed decisions based on specific project needs regarding insulation properties, durability expectations, environmental factors such as moisture exposure or coastal conditions. Each material presents distinct advantages that cater to diverse construction requirements while also posing unique challenges that must be carefully addressed.

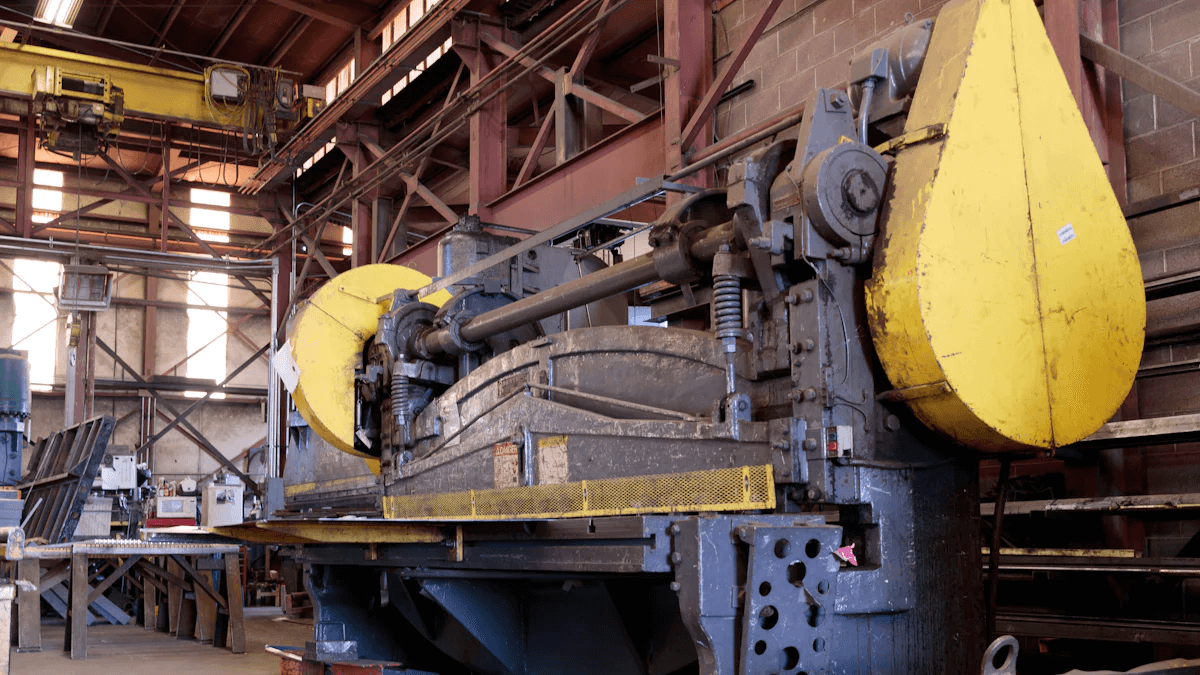

The Role of Purlin Machines in Modern Construction

In modern construction, the utilization of purlin roll forming machines has revolutionized the manufacturing process of purlins, offering enhanced efficiency and precision. These machines play a pivotal role in shaping raw materials into customized purlin profiles, catering to diverse construction requirements.

Introduction to Purlin Roll Forming Machine

How It Works

A purlin roll forming machine operates by gradually shaping metal coils or sheets into consistent purlin profiles through a series of sequential bending and rolling processes. This automated system ensures precise dimensions and uniformity in the produced purlins, meeting the exact specifications required for different construction projects.

Benefits in Purlin Manufacturing

The introduction of purlin roll forming machines has significantly streamlined the manufacturing process, offering several advantages such as:

·Enhanced Precision: These machines enable the production of accurately shaped purlins with minimal material wastage, ensuring cost-effective manufacturing.

·Customization Capabilities: Builders can tailor the dimensions and configurations of purlins according to specific project requirements, facilitating versatile applications across various structural designs.

·Time Efficiency: The automated nature of these machines expedites the production process, reducing lead times and enhancing overall construction timelines.

·Consistent Quality: By minimizing human error and variations, purlin roll forming machinesensure consistent quality in every produced purlin, contributing to structural reliability.

Choosing the Right Purlin Machine

Factors to Consider

When selecting a purlin roll forming machine, builders should consider several key factors to ensure optimal functionality and compatibility with their manufacturing needs:

·Material Compatibility: The machine’s capability to work with different materials such as steel or aluminum is crucial for accommodating diverse project specifications.

·Profile Flexibility: Builders should assess the machine’s capacity to produce a wide range of purlin profiles, allowing for versatility in design implementation.

·Automation Features: Evaluating the level of automation offered by the machine is essential for maximizing production efficiency while minimizing manual labor requirements.

·Maintenance Requirements: Understanding the maintenance protocols and serviceability aspects of the machine is vital for long-term operational sustainability.

·Scalability Options: Considering future expansion needs and scalability options within the machine’s capabilities ensures adaptability to evolving project demands.

Impact on Construction Efficiency

The integration of an efficient purlin roll forming machine directly influences construction efficiency by:

·Streamlining Production Processes: By automating purlin manufacturing, these machines reduce production lead times and enhance overall construction workflow efficiency.

·Ensuring Consistency: The uniformity achieved through automated manufacturing contributes to structural integrity while minimizing installation challenges on-site.

·Cost Optimization: Efficient production translates to cost savings through reduced material wastage and enhanced resource utilization during construction activities.

Xinbo Machine Making Co. Ltd, established in China since 2014, is a manufacturer of roll forming machines. Xinbo’s purlin roll forming machines are used in the construction industry to produce high-quality purlins, which are used to support the roof and walls of buildings. These machines are designed to produce purlins in various sizes and shapes, depending on the requirements of the building project.

These machines are highly efficient and can produce a large number of purlins in a short amount of time. They are easy to operate and require minimal maintenance, making them a cost-effective solution for any construction project.

Xinbo also offers U and Z purlin roll forming machines and CZ purlin machines. The CZ purlin machine is a kind of interchangeable production line that can make C-shaped or Z-shaped purlins after punching, leveling, cold bending, forming, length fixing, and cutting of hot and cold rolled steel strips. Two types of conversion and specification adjustment can be realized through relevant adjustment, including manual adjustment and automatic adjustment.

Making the Right Choice: Factors to Consider

When it comes to selecting the most suitable purlin material for a construction project, builders must carefully assess various factors to ensure optimal performance and longevity of the roofing system. The decision-making process involves evaluating building requirements, cost considerations, as well as material availability and sustainability.

Assessing the Building Requirements

Load Bearing Needs

Understanding the load-bearing requirements of the structure is paramount in determining the appropriate purlin material. Factors such as roof design, anticipated snow loads, wind forces, and potential equipment or HVAC installations on the roof influence the choice of purlins. Steel purlins are known for their exceptional load-bearing capacity, making them suitable for structures with heavy roofing materials or significant environmental loads. On the other hand, wood purlins may suffice for lighter roofing applications where insulation properties are a priority.

Environmental Considerations

Environmental factors play a crucial role in material selection, especially in regions prone to high humidity, coastal exposure, or extreme temperature variations. Builders need to consider how each material responds to moisture, corrosion resistance, and long-term durability in challenging environmental conditions. Aluminum purlins offer rust resistance and are well-suited for coastal areas due to their ability to withstand salt-laden air. Conversely, steel purlins with proper galvanized coatings provide robust protection against corrosion in diverse climatic settings.

Cost vs. Longevity

Initial Investment

The initial cost outlay for purlin materials is a significant consideration in construction budgeting. While wood may present a lower upfront investment compared to steel or aluminum, builders must weigh this against long-term maintenance and replacement costs. Steel’s higher initial investment is often justified by its extended lifespan and minimal maintenance requirements over time. Aluminum’s lightweight nature may contribute to easier installation but could entail higher material costs depending on market fluctuations.

Maintenance and Replacement Costs

Long-term maintenance and replacement expenses should be factored into the decision-making process when selecting purlin materials. Wood purlins may require more frequent inspections and treatments to mitigate rot or pest infestations, adding ongoing maintenance costs over their lifespan. In contrast, steel and aluminum purlins offer greater longevity with minimal maintenance needs, potentially resulting in lower overall lifecycle expenses.

Availability and Sustainability

Material Availability

The accessibility of raw materials plays a pivotal role in ensuring timely project execution without supply chain disruptions. Builders should consider local availability of wood products or metal alloys required for manufacturing purlins when making material choices. Steel enjoys widespread availability due to its industrial production scale while aluminum availability may vary based on regional manufacturing capacities.

Environmental Impact

Sustainability considerations encompass evaluating the environmental impact of chosen materials throughout their lifecycle. Wood sourced from responsibly managed forests aligns with sustainable construction practices by promoting renewable resources; however, concerns regarding deforestation and carbon footprint exist within this context. Steel’s recyclability contributes to its eco-friendly profile despite energy-intensive production processes while aluminum’s recyclable nature supports environmentally conscious construction initiatives.

Conclusion: Summarizing the Purlin Material Dilemma

Upon thorough analysis of the various purlin materials and their critical role in the construction sector, it is clear that selecting the appropriate material necessitates a deliberate assessment of particular project demands and expectations for long-term durability. The key insights provided below are intended to assist builders in making well-informed choices concerning purlin materials:

Key Takeaways

Best Material for Specific Needs

Each purlin material offers distinct advantages tailored to specific construction needs. Wood purlins excel in providing natural insulation and a visually appealing aesthetic, making them suitable for certain architectural designs. Steel purlins, renowned for their durability and corrosion resistance, are ideal for structures requiring robust load-bearing capacity and longevity. Meanwhile, aluminum purlins present a lightweight yet rust-resistant option suitable for applications where weight considerations and coastal environmental factors come into play.

The Importance of the Right Purlin Machine

In modern construction practices, the utilization of advanced purlin roll forming machines plays a crucial role in ensuring efficient manufacturing processes. These machines offer precision, customization capabilities, and time efficiency, contributing to the seamless production of high-quality purlins tailored to diverse project specifications.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia