Sharp Tool to Reshape the Productivity of Manufacturing Industry–Roll Forming Machine

As the global economy continues to evolve, the significance of enhancing production efficiency within the manufacturing industry – a mainstay of national economies – grows increasingly apparent. Advanced manufacturing equipment, like Roll Forming Machines, is spearheading this transformative initiative. Characterized by their proficiency, precision and energy-efficient attributes, these machines have proven instrumental in redefining and enhancing productivity within the manufacturing sector.

Working Principle of Roll Forming Machine

The Roll Forming Machine is an advanced piece of machinery engineered to implement a process that involves the continuous transformation of material through roll forming. The principal components of this equipment include an integral frame, application-specific rollers, and a driving system for operational processes, alongside extensive control systems and ancillary parts.

During operation, under the influence of the well-regulated driving mechanism, the designated rollers perform rotary movements. In its course, it persistently morphs the material positioned between these rotating elements. Over time and due to uninterrupted interaction with the roller apparatus; these materials undergo progressive deformation. This leads them progressively towards adopting their required formative configuration in due accordance with specific requirements.

The operational dynamics of the roll forming machine are founded on the concept of plastic deformation of materials. This process employs the strategic utility of rollers for continual rolling, facilitating material shaping and molding successfully. When contrasted with commonplace press molding techniques, roll forming offers elevated productivity levels, significantly reduced energy utilization and superior quality in product outcomes.

Advantage analysis of roll forming machine

High production efficiency: Roll forming machine adopts continuous rolling method, which can realize the rapid molding of materials and greatly improve the production efficiency. At the same time, the roll forming machine also has the characteristics of high degree of automation, can realize automatic production, further improve the production efficiency.

Energy saving and consumption reduction: roll forming machine in the molding process, the material is subject to less frictional resistance, so the energy consumption is relatively low. In addition, the roll forming machine can further reduce energy consumption through the design and optimization of the rollers to achieve the goal of energy saving and consumption reduction.

High product quality: Roll Forming Machine can realize uniform rolling of the material during the molding process, avoiding the problems of uneven material and rough surface that may occur in traditional press molding. Therefore, the quality of products produced by roll forming machine is higher and more in line with the market demand.

Wide range of application: Roll Forming Machine can be applied to the molding processing of a variety of materials, such as metals, plastics, rubber and so on. At the same time, roll forming machine can also be customized design and manufacture according to different molding needs, to meet a variety of complex molding requirements.

Application areas of roll forming machines

Roll Forming Machines are widely used in the manufacturing industry due to their unique advantages. The following are some of the major application areas:

Automotive industry: the automotive manufacturing process requires a large number of metal parts and plastic parts, roll forming machine can realize the precise molding of these parts, improve production efficiency and reduce production costs.

Home appliance industry: Many parts of home appliance products, such as shells, brackets, etc., can be produced by roll forming machines. The high efficiency and quality of roll forming machines have led to significant improvements in the productivity and quality of home appliances.

Construction industry: In the construction field, roll forming machines can be used to produce a variety of metal profiles and plastic pipes, providing the construction industry with efficient and environmentally friendly building materials.

Electronic industry: The manufacturing process of electronic products requires the use of a large number of precision parts. Roll forming machine can realize the precise molding of these parts, to meet the electronics industry’s demand for high-precision, high-quality parts.

Conclusion

Roll forming machine with its high efficiency, precision, energy saving features, is gradually becoming an indispensable and important equipment in the manufacturing industry. With the continuous progress of technology and the continuous development of the market, roll forming machine will play a greater role in improving production efficiency, reducing production costs, and improving product quality. At the same time, the development of roll forming machine will also promote the transformation and upgrading of the manufacturing industry and sustainable development. Therefore, we should increase the research and development and promotion of roll forming machine technology, for the development of the manufacturing industry to inject new momentum.

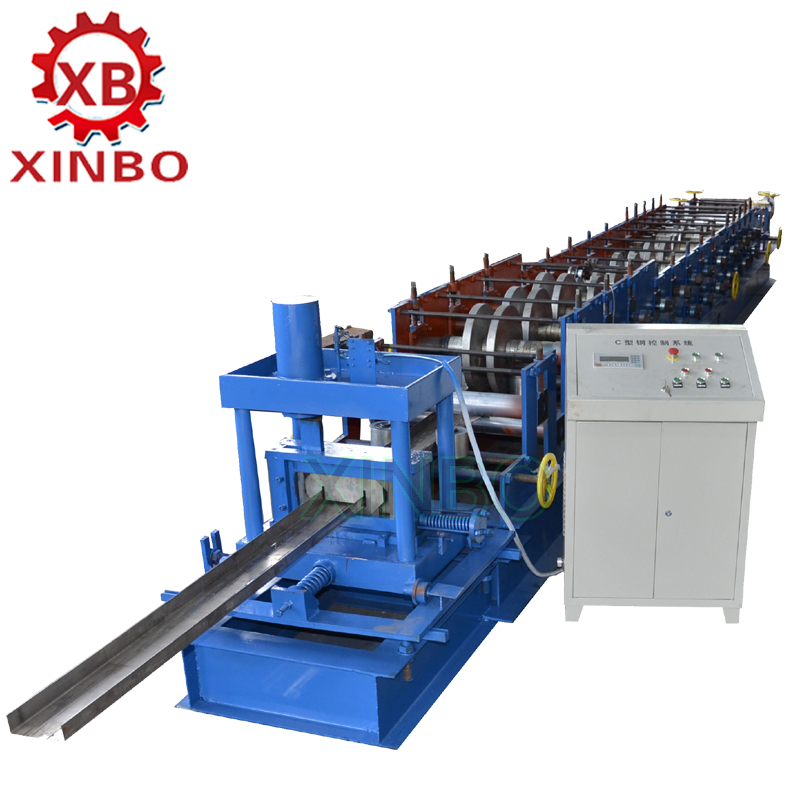

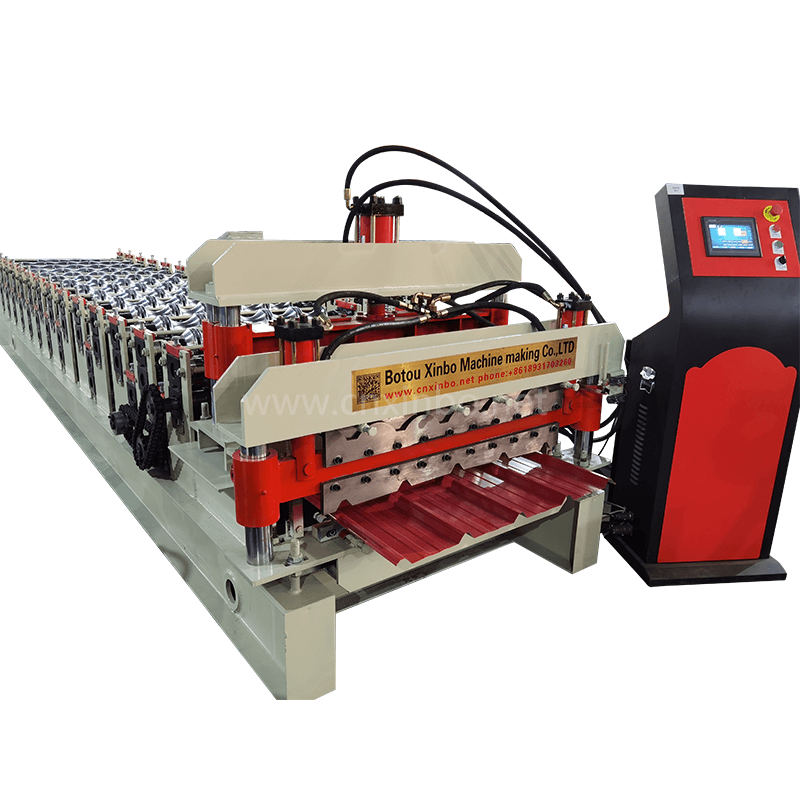

To sum up, the importance and value of roll forming machine as a tool to reshape the productivity of the manufacturing industry is self-evident. In the future development, roll forming machine will continue to play its unique advantages. XinBo is a manufacturer specializing in roll forming machine. Their products include U-channel roll forming machine, purlin roll forming machine, CZ type purlin automatic roll forming machine and UZ type purlin roll forming machine. All of these products have the advantages of high efficiency, easy operation and minimal maintenance requirement, which can help enterprises to improve production efficiency and reduce production cost, contributing to the prosperity and development of manufacturing industry!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia