Roll Forming Machines in the Construction Industry

With the advancement of science and technology, the technical equipment of the construction industry is constantly updating. Scroll machines have been widely used in the construction industry as an advanced manufacturing tool.

Basic Principle of Roll Forming Machine

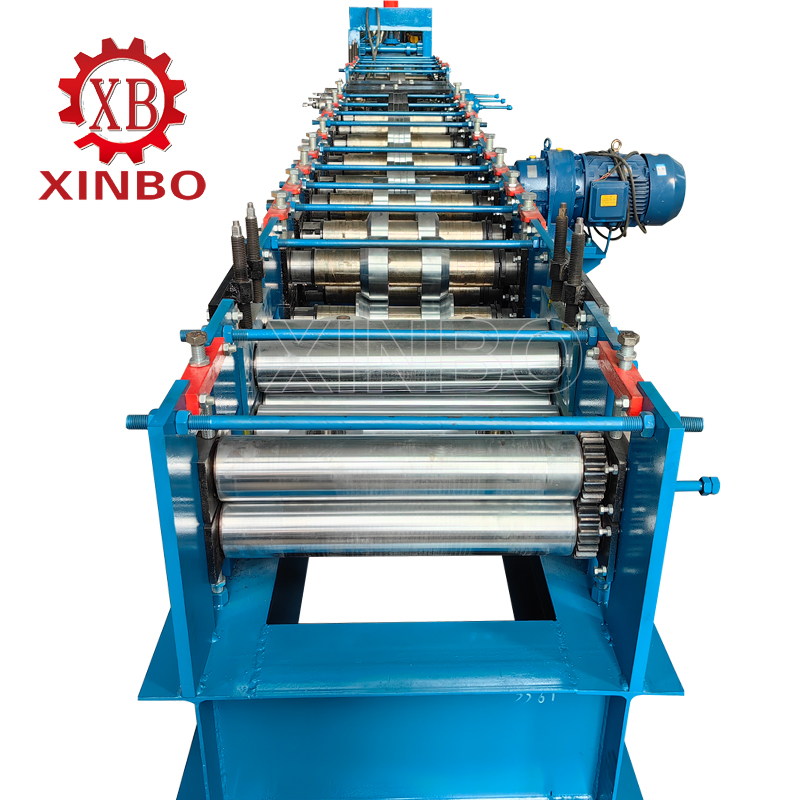

A roll machine is a type of equipment that uses sheet metal to change its shape by continuous rolling to achieve the required rolling shape The basic working principle is to continuously roll the metal sheet through an array of rollers progressively closer to the final cross-sectional shape This method of operation can ensure uniformity and quality of materials, and significantly improve productivity. The working process of the roll-forming machine mainly includes the steps of loading, pre-pressing, main pressing, molding and cutting etc. The whole process is highly automated and easy to use.

Main features of roll forming machine

High efficiency: Roll Forming Machine adopts continuous production mode, which has high production efficiency and can meet the demand of mass production. Its continuous production method can greatly reduce the production cycle and improve production efficiency.

High precision: Roll forming machine has high molding precision, stable product size, smooth surface and reliable quality. Its high precision molding is mainly due to its accurate roller design and precise control system.

Energy saving and environmental protection: the production process of roll forming machine has high material utilization rate, which can effectively reduce waste and save resources, in line with the concept of green environmental protection. Its production process does not require heating, low energy consumption.

Strong flexibility: The roll forming machine can produce products of various shapes and sizes as needed to meet various construction needs. Different shapes of products can be produced by simply changing the rollers.

Application areas of roll forming machine in construction industry

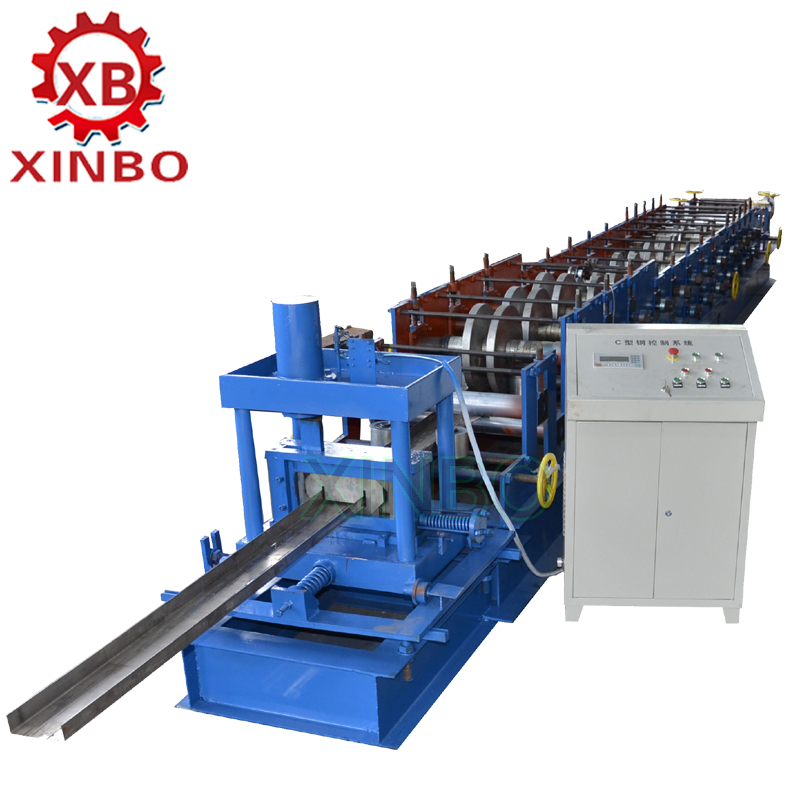

Construction plate production: Roll forming machine is widely used in the production of various construction plates, such as color steel tile, C-beam, Z-beam, floor slabs and so on. These plates have a wide range of applications in the construction industry, such as for building roofs, walls, floor slabs and so on.

Production of building components: Roll forming machines can also be used to produce various building components, such as door and window frames, railings, guardrails and so on. These components also have a wide range of applications in the construction industry, such as for building doors and windows, staircases, balconies and so on.

Building decorative materials production: Roll forming machine can also produce a variety of building decorative materials, such as ceiling panels, wall panels and so on. These decorative materials also have a wide range of applications in the construction industry, such as for the interior and exterior decoration of buildings.

Xinbo’s floor decking roll forming machines also have a wide range of applications in the construction industry. This machine can produce various types of floor decking panels including corrugated panels, trapezoidal panels and other customized shapes. The high efficiency of this machine makes it possible to produce high-quality decking sheets in a short period of time, meeting the needs of the construction industry. In addition, because this machine can be customized to meet specific customer needs, it is very flexible in its application in the construction industry.

Xinbo’s door frame roll forming machines and pipe roll forming machines are also widely used in the construction industry. Door frame roll forming machines can produce door frames of various sizes and shapes to meet different construction needs. Pipe roll forming machines, on the other hand, can produce various types of pipes, including round pipes, square pipes, rectangular pipes, and so on. These pipes are widely used in the construction industry, including water supply, drainage, heating and ventilation.

Xinbo’s rail roll forming machines are used to produce rails, typically for elevators and escalators. This machine can manufacture rails in various sizes and shapes to meet different needs. The use of this equipment not only improves productivity, but also ensures the quality and consistency of the rails.

Roll Forming Machine Trends in the Construction Industry

As the construction industry demands more and more product quality and productivity, roll forming machines will be more widely used. The future roll forming machine will be more intelligent, can realize automatic production, improve production efficiency and reduce production costs. At the same time, the environmental performance of the roll forming machine will also be further enhanced to achieve green production, to meet the social requirements of environmental protection.

Intelligent: The future roll forming machine will be more intelligent and can realize automated production. Through the introduction of artificial intelligence and big data technology, intelligent control of the production process can be realized, improving production efficiency and reducing production costs.

Green production: The environmental performance of roll forming machines will also be further improved. By optimizing the production process, it can further improve the material utilization rate, reduce waste and realize green production.

Diversification: As the construction industry demands more and more diversified product shapes and sizes, roll forming machines will also be able to produce more diversified products to meet various construction needs.

Conclusion

Roll forming machines have been widely used in the construction industry because of their efficiency, accuracy, environmental protection and flexibility. With the development of science and technology, the application of the roll forming machine will expand and its place in the construction industry will become more important so we have to acknowledge the important role of roll forming machine in the construction industry fully acknowledge and highly encourage its use in the construction industry. At the same time, we also need to check the development trend of roll machinery in order to effectively utilize this advanced manufacturing technology to encourage the growth of manufacturing industries.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia