Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→Roll forming machines are indispensable in the modern manufacturing landscape. These machines use a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through consecutive sets of rolls at room temperature to produce a desired shape. This technology is particularly beneficial for creating complex cross-sections with high precision and consistency. The entire process is automated, allowing manufacturers to produce components in large volumes with minimal human intervention, thus ensuring high efficiency and reducing production errors.

XINBO is a company that offers custom services with a focus on efficient design, competitive pricing, short delivery times, and stringent quality inspection. Customers can rely on XINBO to provide them with high-quality products that meet their specific requirements.

The evolution of roll forming technology dates back to the early 20th century. Initially, roll forming machines were rather rudimentary, focusing on basic metal shaping. However, over the decades, technological advancements have revolutionized these machines. With innovations in computer-aided design (CAD) and computer numerical control (CNC) systems, modern roll forming machines are now capable of intricate designs and precise measurements. This historical progression has enabled the technology to become a staple in various industrial sectors, constantly evolving to meet the rigorous demands of modern manufacturing.

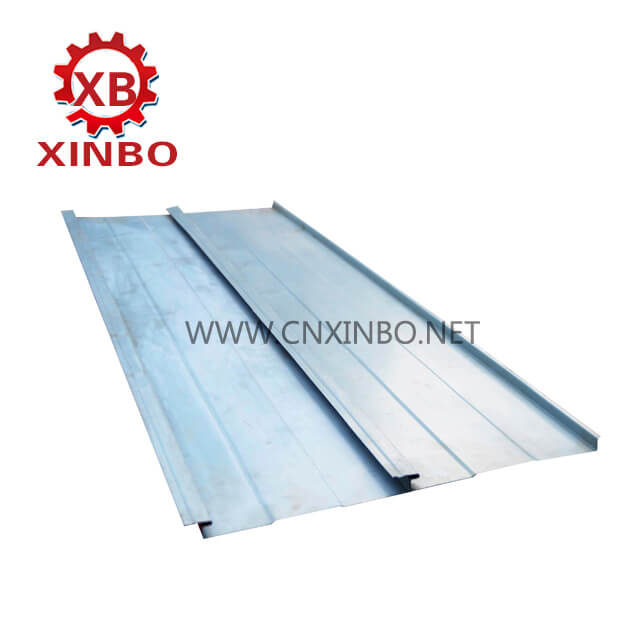

Roll forming machines are utilized in an array of industries due to their versatility and efficiency. The automotive industry extensively uses them to manufacture vehicle components such as frames, bumpers, and panels. The construction sector benefits from roll forming machines for creating steel structures, roofing, and guttering systems. Additionally, the aerospace industry relies on roll forming for producing lightweight, durable parts. Other sectors like agriculture, transportation, and household appliance manufacturing also employ roll forming machines to streamline production and enhance product quality.

One of the significant environmental benefits of roll forming machines is the efficient use of raw materials. The precision of the roll forming process ensures that the exact amount of metal needed for a specific part is used, significantly reducing excess material. This meticulous approach minimizes the production of off-cuts and remnants that typically contribute to waste in other manufacturing methods. The efficiency in raw material usage is not only environmentally friendly but also cost-effective, allowing manufacturers to optimize their resources.

Scrap metal is a common byproduct in manufacturing, but roll forming machines effectively address this issue. The continuous nature of the roll forming process means that there are fewer interruptions, which reduces the likelihood of errors and the generation of defective products. This results in a remarkable decrease in scrap production compared to traditional stamping or machining processes. The reduction in scrap not only conserves raw materials but also lessens the burden on recycling systems, further contributing to environmental sustainability.

Energy conservation is another key area where roll forming machines have a positive environmental impact. Traditional manufacturing methods like stamping or machining often require significant energy input, particularly when heating processes are involved. In contrast, roll forming operates at room temperature and utilizes a continuous process that minimizes energy consumption. This energy-efficient approach not only reduces the operational costs for manufacturers but also lessens their carbon footprint, aligning with global efforts to combat climate change.

In recent years, advancements in electric-powered roll forming machinery have taken energy efficiency even further. Modern roll forming machines are increasingly being designed with electric drives that are more efficient and environmentally friendly compared to older, hydraulic-powered systems. These electric machines offer improved control and consistency, leading to higher quality products while consuming less power. As the industry continues to innovate, the shift towards more sustainable, electric-powered machinery highlights the ongoing commitment to reducing the environmental impact of manufacturing activities.

Roll forming machines can significantly contribute to sustainable development by leveraging recyclable and eco-friendly materials. The technology allows the use of high-strength, lightweight materials like aluminum and advanced high-strength steels (AHSS), which are often recyclable and have a lower environmental impact. By employing these sustainable materials, manufacturers can reduce the use of non-renewable resources and mitigate the overall environmental footprint of their products. In addition, the compatibility of roll forming machines with such materials ensures the continuous push towards more environmentally conscious manufacturing practices.

Innovations in green manufacturing techniques are further enhancing the sustainability of roll forming applications. Advanced technologies now enable the use of less energy-intensive processes and environmentally benign lubricants and coatings. Moreover, integrated waste management systems and closed-loop recycling methods are being adopted to ensure that by-products are efficiently reused or recycled. These green manufacturing techniques not only contribute to sustainable development but also align roll forming processes with stringent environmental regulations, promoting industry-wide adoption of eco-friendly practices.

Roll forming machines play a pivotal role in supporting green building initiatives by providing customized, energy-efficient components for eco-friendly construction projects. The high precision of roll-formed parts ensures that building materials are manufactured with minimal waste, contributing to the overall sustainability of construction projects. Furthermore, the ability to produce lightweight, high-strength building elements such as steel beams, panels, and roofing systems helps improve the energy efficiency and structural integrity of green buildings.

Using roll-formed products in construction also enhances the sustainability and lifespan of buildings. The superior durability and strength of roll-formed components mean that structures require less frequent repairs and replacements, thus conserving materials and reducing waste over time. Additionally, roll-formed products can be engineered to include recyclable content, supporting the circular economy in the construction industry. By integrating roll-forming technology in construction, developers can create more resilient and sustainable buildings that promote long-term environmental stewardship.

While roll forming machines offer numerous environmental benefits, they also present certain challenges that need to be addressed to maximize their sustainability potential. One such challenge is the control and reduction of emissions generated during the manufacturing process. Innovative filtration and ventilation systems are being developed to capture and minimize harmful particulates and volatile organic compounds (VOCs). By implementing stringent emissions control initiatives, manufacturers can significantly reduce the environmental impact of roll forming processes, aligning their operations with global sustainability goals.

Effectively managing industrial by-products and waste is another crucial aspect of enhancing the sustainability of roll forming machines. Developing efficient waste management systems that prioritize the recycling and repurposing of by-products can considerably reduce the amount of waste sent to landfills. Companies are also investing in research to find innovative uses for industrial by-products, such as repurposing metal scrap for other manufacturing processes. These efforts are pivotal in promoting a zero-waste approach within the roll forming industry.

The future of roll forming is poised to witness significant advancements aimed at further enhancing sustainability. Emerging trends such as the integration of artificial intelligence (AI) and machine learning (ML) in process optimization are expected to lead to more efficient and environmentally friendly production methods. AI and ML can predict equipment malfunctions, optimize material usage, and minimize energy consumption, thereby promoting more sustainable manufacturing practices. Additionally, advancements in automation and robotics will likely improve precision and reduce waste, further contributing to environmental conservation.

Ongoing research and development (R&D) efforts are also crucial in driving the sustainability of roll forming technologies. Researchers are exploring eco-friendly solutions, such as bio-based lubricants and advanced coatings that reduce the environmental impact of the roll forming process. R&D initiatives are also focusing on developing new materials and improving existing ones to make them more recyclable and sustainable. These continuous innovations are essential for pushing the boundaries of what roll forming machines can achieve in terms of environmental protection and sustainable development.

ies and Policymakers

ies and PolicymakersFor industries leveraging roll forming machines, implementing sustainable practices is no longer a choice but a necessity. Companies can start by conducting comprehensive environmental audits to identify areas where improvements can be made. Adopting best practices such as energy-efficient machinery, waste reduction techniques, and the use of recyclable materials can significantly reduce their environmental footprint. Moreover, investing in employee training programs focused on sustainability can ensure that the workforce is well-prepared to support eco-friendly manufacturing initiatives.

Policymakers play a critical role in fostering an environment where sustainable manufacturing practices can thrive. They can incentivize companies to adopt green technologies and invest in roll forming machines that prioritize environmental sustainability. Additionally, implementing stricter regulations on emissions, waste management, and resource usage can push industries towards more responsible manufacturing practices. By collaborating with industries, policymakers can create frameworks that support sustainable development while ensuring that economic growth is not compromised.

The positive impact of roll forming machines on eco-sustainability highlights the crucial role of innovative manufacturing technologies in addressing environmental challenges. As industries and policymakers continue to prioritize sustainability, the integration of advanced roll forming machines will undoubtedly pave the way for a greener and more sustainable future. Through continuous efforts in research, development, and the implementation of eco-friendly practices, roll forming machines can contribute significantly to the global push towards environmental protection and sustainable development.

XINBO special designing as customer need, also allows the machines loaded in to a standard 40ft HQ container. The savings on logistic is essential for international clients. Our factory has ourself professional Engineers and designers, who can design the detail drawings as customers’need in short time. And keep the exactly same. We has ourself workshop and CNC machining machines and workers, this will save many cost and keep the process in same time with each steps. Designing and CNC. Each machine will be inspected in 3 times before shipping to customers.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→