Roll Forming Machine vs. Traditional: A Detailed Comparison

In the realm of metal fabrication, selecting between a roll forming machine and conventional forming processes can greatly influence efficiency, cost, and product quality. By comprehending both methods, manufacturers and businesses can make well-informed choices that improve production capabilities. This article provides a comparative analysis of roll forming machines versus traditional forming techniques, exploring their operational mechanics and applications while emphasizing the key differences between them.

Understanding Roll Forming Machines

What is a Roll Forming Machine?

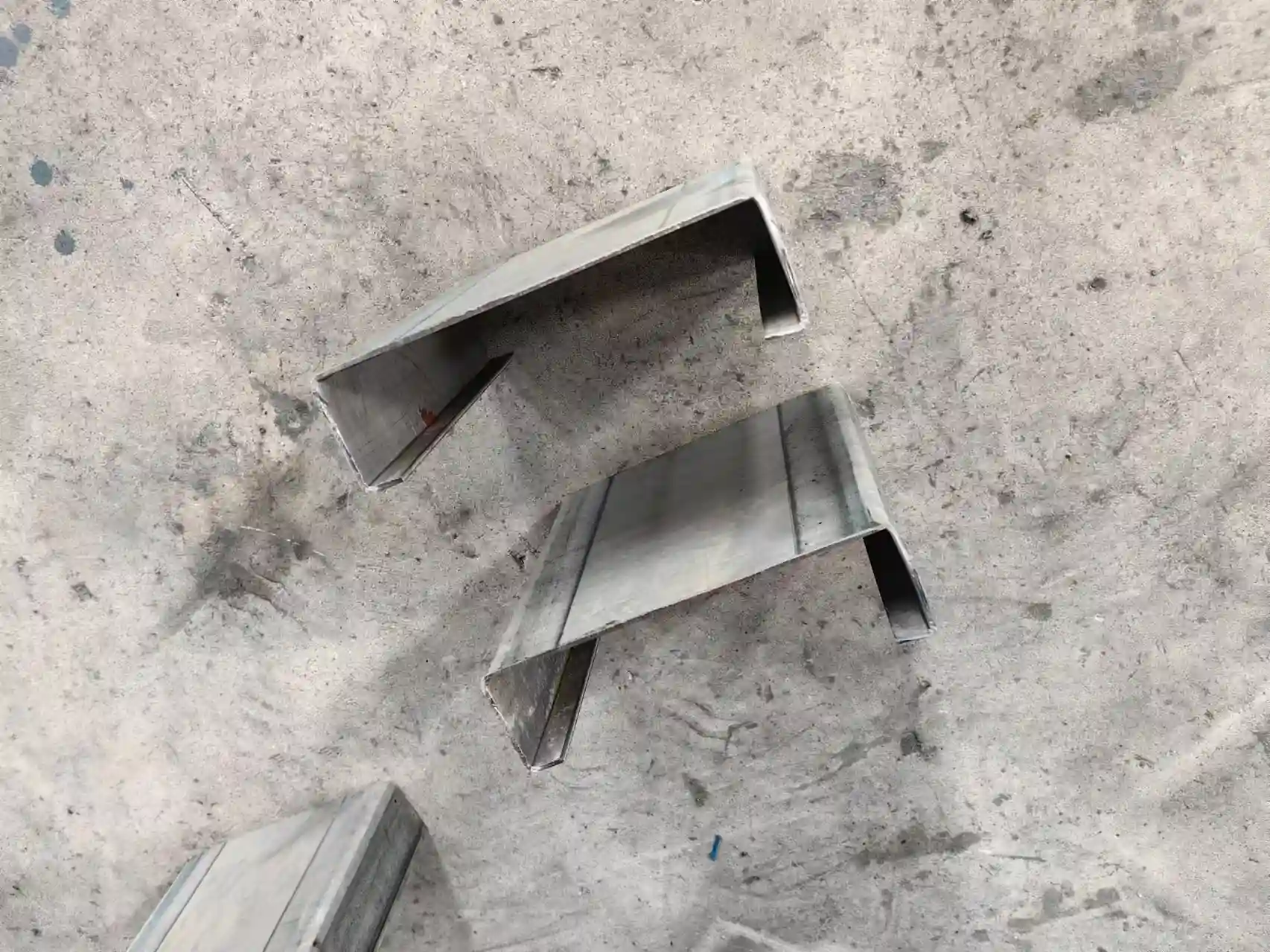

A roll forming machine is a type of equipment used in the manufacturing process that shapes metal sheets into desired profiles by passing them through a series of rollers. This machine is designed to gradually bend the material along its length, creating uniform and precise shapes. Typically made of durable materials, these machines are essential for industries that require consistent production of specific metal forms like channels, angles, and brackets.

How Roll Forming Machines Work

The operation of a roll forming machine involves a continuous and automated process where flat metal strips are fed into a series of rollers, each designed to make incremental bends. The metal is progressively shaped until it reaches its final form. This process is highly automated, allowing for high production rates with minimal manual intervention. Roll forming can also accommodate various materials, including steel, aluminum, and copper, making it an adaptable choice for many manufacturing requirements.

Common Applications of Roll Forming Machines

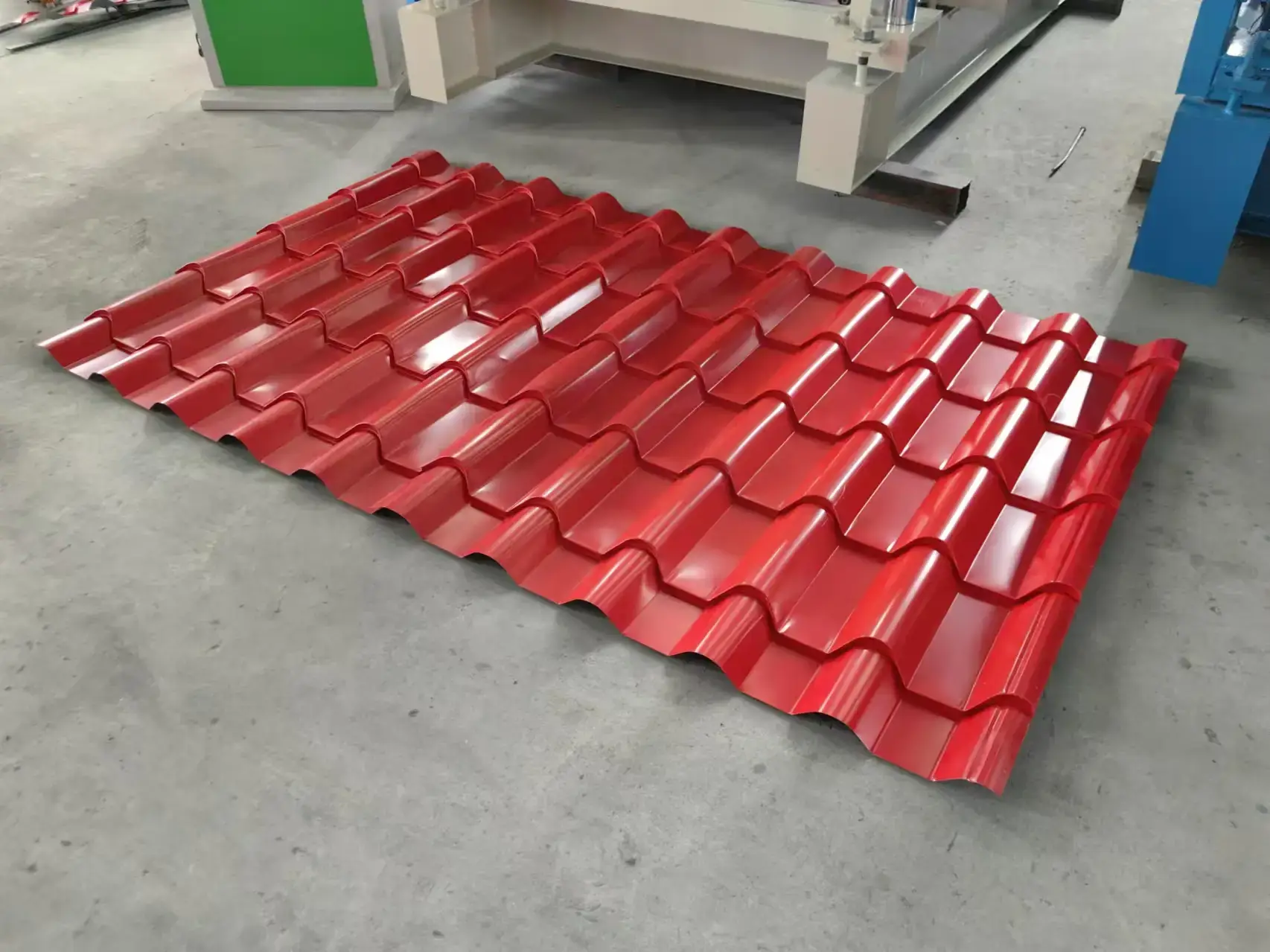

Roll forming machines are widely used across various industries, including construction, automotive, and appliances. They are essential for producing components such as roofing panels, door frames, and window wells. The ability to create long runs of consistent product profiles ensures that manufacturers can meet high-volume demands while maintaining quality and precision, making them indispensable in modern metal fabrication.

Exploring Traditional Forming Processes

Overview of Traditional Forming Methods

Conventional forming techniques include bending, stamping, and forging. These methods often depend on manual labor and specialized machinery tailored for particular tasks. Although these processes are capable of generating high-quality products, they typically require more labor and longer production timelines when compared to contemporary techniques like roll forming machines.

Typical Machinery in Traditional Forming

In traditional forming, equipment such as press brakes, mechanical and hydraulic presses, and manual benders are commonly used. Each machine operates differently, often requiring skilled operators to manage the machinery and ensure quality output. Traditional forming processes can lead to increased labor costs and setup times, which can complicate production schedules.

Common Uses of Traditional Forming Processes

Traditional forming techniques are prevalent in industries such as heavy machinery, agricultural equipment, and custom fabrication. These methods are often employed to manufacture unique parts or low-volume products that require custom shapes or intricate designs. While effective for specific applications, traditional forming may not match the efficiency of roll forming machines in high-volume scenarios.

Key Differences Between Roll Forming and Traditional Techniques

Process Efficiency

The efficiency between roll forming machines and traditional forming methods varies significantly. Most notably, roll forming achieves higher production speeds because the process is continuous, minimizing downtime. In contrast, traditional methods typically involve multiple setup changes for different parts, resulting in longer lead times.

Production Speed

Roll forming machines are capable of producing parts at a remarkable speed, often reaching production rates of hundreds of feet per minute. In contrast, traditional forming processes tend to be slower, especially when multiple tools or setups are required. This disparity significantly impacts production efficiency and the ability to meet demand.

Energy Consumption

Energy consumption is another critical factor. Roll forming machines are designed to be energy efficient, generally consuming less power per unit produced in comparison to traditional machinery, which may require more energy due to the various stops and starts throughout the manufacturing process.

Material Handling and Waste Reduction

In terms of material handling and waste reduction, roll forming machines excel. The continuous nature of roll forming minimizes scrap materials since the strips are processed in a linear fashion without the need for multiple cuttings seen in traditional methods. This not only makes roll forming more economical but also environmentally friendly.

Versatility and Customization Possibilities

Roll forming machines offer considerable versatility, as they can create a wide variety of shapes using the same setup once the tooling is in place. Traditional methods may need significant reconfiguration for different products, which can lead to increased costs and extended lead times.

Advantages of Roll Forming Machines

Cost-Effectiveness

One significant benefit of using a roll forming machine in a manufacturing environment is the cost savings realized through reduced labor and material expenses. The automated process of roll forming minimizes the need for overtime work and decreases setup times, leading to lower production costs per unit overall.

Precision and Consistency

Achieving Tight Tolerances

Roll forming machines provide high levels of precision and consistency in production. With automated control systems, these machines can achieve tight tolerances that are often challenging to maintain in traditional processes. This precision is particularly crucial for industries that require strict specifications in their products.

Minimizing Material Waste

Roll forming is recognized for minimizing material waste, as it makes efficient use of the raw materials being processed. The continuous feed method reduces scrap rates and the overall consumption of materials, making it a more sustainable option when compared to traditional methods.

Safety Considerations

The use of roll forming machines also contributes to improved safety in manufacturing environments. Many modern roll forming machines come equipped with advanced safety features that seamlessly integrate into their automated operations, reducing the risk of worker injury compared to traditional manual processes.

Challenges Associated with Roll Forming Machines

Initial Investment Costs

Investing in a roll forming machine can be a substantial commitment. The initial expenditure linked to acquiring a roll forming system is often higher than that of conventional forming equipment. This encompasses the cost of buying the machine itself, along with additional expenses for tooling needed for specific applications. Companies must consider this upfront financial outlay against the long-term benefits, such as improved operational efficiencies and lower labor costs, which may lead to a favorable return on investment over time.

Ongoing Maintenance Requirements

While roll forming machines offer numerous advantages, they also come with ongoing maintenance needs. Regular servicing and checks are essential to ensure optimal performance and to prevent unexpected downtimes that could disrupt production schedules. This can translate to additional costs for manufacturers who must allocate resources for routine maintenance or repairs. While maintenance requirements are generally more predictable compared to traditional machinery, businesses need to factor these into their operational plans to maintain the efficiency of the roll forming process.

Choosing the Right Method for Your Needs

Factors to Consider

When deciding between a roll forming machine and traditional forming methods, several critical factors come into play. Companies should start by assessing their budget constraints, understanding how much they can allocate towards either option. This financial evaluation often helps frame the efficiency and productivity expectations based on the available resources. Additionally, specific material requirements play a crucial role; not all materials are suitable for every type of forming process, so the chosen method must align with the material properties to avoid production complications.

Budget Constraints

Budget considerations are paramount for any manufacturing decision. For companies with limited financial resources, the upfront investment associated with a roll forming machine may seem daunting. In contrast, traditional forming methods can sometimes allow for lower initial costs but might result in higher long-term expenses due to increased labor and slower production speeds. Analyzing short-term and long-term financial impacts can aid businesses in making a decision that balances immediate capabilities against future growth potential.

Specific Material Requirements

Manufacturers select forming methods based on specific material requirements. Roll forming machines are versatile, handling a variety of materials including steel, aluminum, and different alloys, whereas traditional methods may face limitations depending on the machinery. Certain materials may necessitate custom setups in traditional processes, which can increase costs and extend lead times. It’s crucial for businesses to assess how well their preferred materials align with both forming methods to guarantee that the chosen solution consistently meets their production objectives.

Desired Production Volumes

Production volume expectations also greatly influence the decision between roll forming machines and traditional methods. For high-volume production, roll forming is typically the more favorable option, providing accelerated output and consistent quality. Conversely, if a manufacturer anticipates low-volume needs or sporadic production runs, traditional forming might suffice. Therefore, understanding production projections is crucial in selecting the most appropriate forming technique that aligns with strategic objectives.

Case Examples of Appropriate Applications

There are various scenarios where one forming method may serve as a better choice than the other. For example, a company specializing in production for the automotive sector producing large numbers of consistent components, such as chassis or brackets, would benefit greatly from a roll forming machine due to its efficiency and precision. On the other hand, a custom fabrication shop, known for producing low-volume, bespoke parts that require intricate designs, might find traditional forming techniques more suited to their operational needs. Each application presents unique requirements, highlighting the importance of a tailored approach when selecting forming methodologies.

An Introduction to Xinbo and Their Offerings

Overview of Xinbo’s Expertise in Manufacturing Solutions

Xinbo is a recognized leader in the manufacturing solutions industry, offering an extensive range of equipment and support for various metal fabrication needs. The company focuses on delivering high-quality roll forming machines that enhance productivity while simplifying the forming process for businesses of all sizes. With years of experience in the industry, Xinbo is equipped to provide personalized solutions that cater specifically to the diverse demands of their clients.

Company Background

Founded with a mission to propel metal processing technology forward, Xinbo has evolved into a distinguished entity within the manufacturing sector. Their dedication to quality and innovation is evident in their product designs, which incorporate the most recent advancements in engineering. Xinbo’s skilled team comprehends the complexities of various forming processes and provides insights that assist companies in making well-informed decisions about their equipment requirements.

Range of Products and Services Offered

Xinbo offers a comprehensive array of products, including advanced roll forming machines, customized tooling, and related support services. They cater to diverse industries, ensuring that every product aligns with specific customer requirements for quality and efficiency. Beyond manufacturing solutions, Xinbo also offers training and technical support to ensure effective machine utilization and longevity.

Why Choose Xinbo for Your Forming Needs?

Choosing Xinbo for your forming needs means benefiting from an unwavering commitment to quality, precision, and customer satisfaction. Their advancements in technology make them a preferred partner for those looking to invest in roll forming machines. With a thorough understanding of market demands and challenges faced by manufacturers, Xinbo ensures that every solution is tailored to not only meet but exceed client expectations.

Summary of Comparative Insights

In conclusion, both roll forming machines and traditional forming processes have their unique advantages and drawbacks that can significantly affect manufacturing operations. While roll forming boasts superior efficiency, cost-effectiveness, and precision, traditional methods can better serve custom or low-volume production needs. Manufacturers must also consider initial investment costs, ongoing maintenance requirements, and specific production goals when choosing the right process for their applications. Companies like Xinbo provide valuable insights and tailored solutions, ensuring that businesses can navigate their options effectively and choose the best forming method that meets their production needs.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia