Roll forming machine expertise:Explore daily applications of Spandrells Machine

Understanding the Role of Roll Forming Machines in Modern Manufacturing

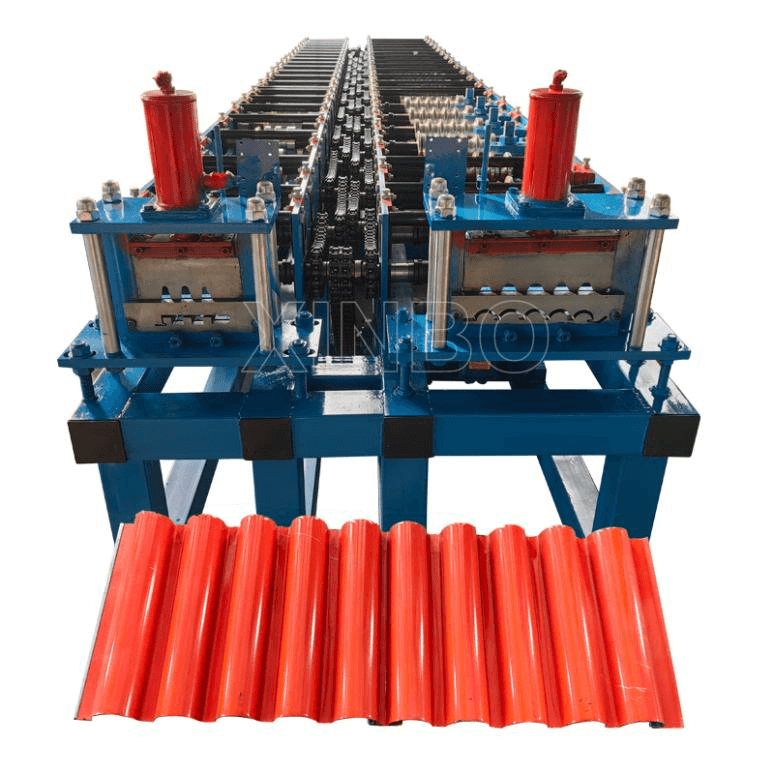

Overview of Roll Forming Machines

Roll forming machines play a role, in today’s manufacturing industry by allowing metal sheets to be bent continuously into shapes with the help of rollers in a precise and consistent manner. These machines are popular among manufacturers for their efficiency in reducing wastage while creating profiles seamlessly through an automated process. This seamless transformation is vital for producing a range of components, in industries.

Principles and Functionality

The key concept of roll forming machines lies in their capacity, for bending as they guide metal through a series of rollers to shape it gradually into the desired profile with precision and efficiency. The careful arrangement of rollers ensures that each bend is executed at the angle and depth during the process. This method enables the creation of profiles in lengths while achieving top-notch finishes and minimizing the requirement for additional finishing steps. Additionally, roll forming is versatile in handling materials such as metals and thicknesses, with ease.

Key Components of Roll Forming Machines

The essential parts of the roll forming machine are its elements that are carefully designed for top-notch efficiency and performance optimization; a decoiler, for unwinding the metal strip; rollers that mold the metal; and a cutoff mechanism to produce final lengths of the metal product smoothly and accurately. The machine’s base is crafted to hold the materials in position as they move through the roller system seamlessly. Controls and sensors play a role by overseeing and fine-tuning the operation in time to ensure accuracy and flexibility during production processes.

Advancements in Roll Forming Technology

In the realm of roll forming technology, these days are making strides in boosting production capabilities better, than before. If we talk about advancements such as computer numerical control (often referred to as CNC) it’s playing a role in increasing automation and precision levels in manufacturing processes. These systems are now capable of churning out profiles with the need for human intervention – thus lowering the chances of errors creeping in. Additionally, new developments in roller designs and materials have resulted in machinery that requires less frequent maintenance. This evolution is, about making sure that manufacturers can keep up with the demands of industries while still maintaining top-notch productivity levels.

Spandrells Machine: A Specialized Roll Forming Machine

Introduction to Spandrells Machine

The spandrells machine represents a specialized segment in roll forming technology, tailored specifically for creating architectural spandrels and similar components. This machinery boasts a unique design that optimizes the formation process, allowing for versatility in producing both standard and customized profiles. With a focus on architectural applications, the spandrells machine has positioned itself as an essential tool for manufacturers seeking to cater to the construction and design industries.

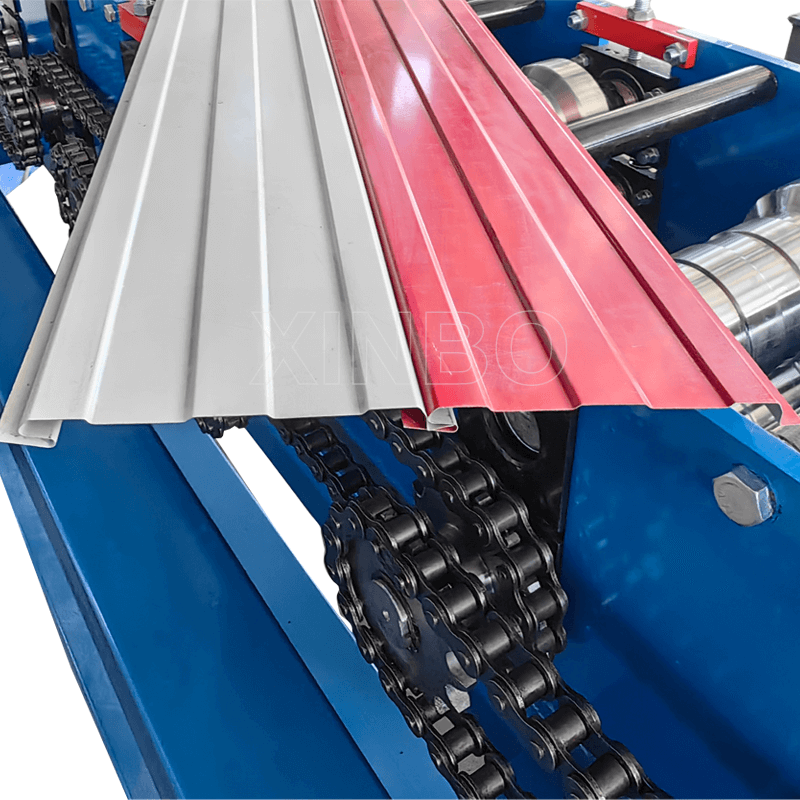

Distinct Features and Capabilities

One of the standout features of the spandrells machine is its ability to produce complex designs with exceptional accuracy. The machine offers versatility in terms of the types of metals it can process, making it suitable for a wide range of applications. Its advanced control systems provide the flexibility to adjust to varying specifications without extensive downtime, significantly enhancing production efficiency. Additionally, the machine’s robust construction ensures reliability, enabling it to handle long production runs without compromising quality.

Applications Specific to Spandrells Machine

The applications of the spandrells machine extend beyond simple roll forming. It excels in the creation of decorative spandrels used in building facades, allowing architects to push the boundaries of design. The precision offered by this machinery makes it ideal for producing intricate architectural elements that require both aesthetics and structural integrity. Furthermore, its compatibility with various coatings and finishes enhances the end product’s visual appeal, making it a preferred choice for contemporary construction projects.

Materials Processed by spandrells machine

Metal Types (Steel, Aluminum, etc.)

The spandrells machine is skilled, at working with metals such as steel and aluminum often utilized in building and design projects. The durable and strong characteristics of steel make it a popular option for parts while the lightweight quality and resistance to corrosion of aluminum add to its attractiveness, for purposes. The machine’s adaptable structure allows for the use of these materials empowering manufacturers to create a range of spandrels and architectural elements customized to meet project needs.

Composite Materials

The spandrells machine is not capable of working with metals but proficient in dealing with composite materials to cater to a wide range of projects effectively and efficiently. Composites bring their set of advantages, like enhanced insulation and versatile aesthetics into the mix. The machine is designed with precision to handle the properties of these materials ensuring that the end product maintains its quality and integrity without compromise. This flexibility empowers architects and designers to innovate by blending the strengths of both metal and composite materials in their design endeavors.

Examining Daily Applications of spandrells machine in Various Industries

Construction and Building Sector

In the construction fields landscape lies the crucial spandrell machine that significantly contributes to crafting components that boost both strength and visual allurement alike. A standout use of this technology lies in its ability to fabricate ceiling panels, for indoor spaces. The accuracy and tailored output of the spandrell machine empower architects to bring their design visions to life faithfully by guaranteeing that the final panels meet both practical demands.

Usage in Ceiling Panels

The spandrells machine produces ceiling panels that come in shapes and finishes to give architects the freedom to align them with a building’s design concept. These panels can have coatings, for looks and durability. Moreover the process of roll forming guarantees that each panel is consistent, in size which helps cut down on installation time and labor expenses at the construction site.

Advantages of Wall Cladding Systems

The spandrell machine is great, at producing wall cladding systems that provide both protection and a stylish look. Materials processed by this machine can be customized for dimensions and different surface finishes to meet the needs of architectural styles. This feature does not boost energy efficiency in buildings. Also strengthens their resistance to weather conditions. The blend of functionality and visual appeal makes the spandrell machine an important tool, for construction endeavors.

Custom Architectural Elements

Moreover, the machine’s capacity to create elements enables designers to incorporate distinctive characteristics into their projects. From profiles to structural parts, the spandrell machine offers the accuracy and excellence required for upscale buildings. This flexibility is crucial, in an industry where unique design elements can yield benefits.

Automotive Industry Applications

The automotive sector greatly profits from the functions of the spandrell machine in producing car body parts efficiently using roll forming technology to make lightweight components that enhance vehicle performance in general.

Production of Vehicle Body Parts

Roll forming machines, including the SPANDRELLS MACHINE, enable the efficient mass production of various body parts, such as reinforcements and structural elements. The precision of the roll forming process ensures that components meet stringent automotive standards, maintaining safety and performance. Additionally, the flexibility of the SPANDRELLS MACHINE allows for the production of components that cater to evolving automotive designs and technologies.

Interior Panels and Reinforcements

Additionally, the spandrells machine plays a role, in crafting panels and reinforcements that improve both the visual appeal and practical functionality of automobiles. These parts can seamlessly blend into the vehicle’s design while retaining their properties – an important factor in contemporary car engineering. The machine’s capability to fabricate custom shapes and sizes with precision is essential, for guaranteeing a fit of these components and enhancing the quality of the vehicle.

Electronics Enclosures and Cabinets Manufacturing

In the field of electronics industry, spandrell’s device is commonly used for creating enclosures and cabinets. These parts play a role, in safeguarding electronic devices while also offering a structured layout, for internal wiring and components.

Benefits of IT Infrastructure Design

The spandrell machine excels, in accuracy and effectiveness to streamline the production of enclosures tailored to the requirements of IT infrastructure design. By prioritizing both functionality and visual appeal manufacturers can create enclosures that harmonize with settings while ensuring sturdy defense, against environmental elements.

Fabrication of Protective Housings

Moreover, the spandrell machine has the ability to manufacture casings for a range of electronic devices. Its flexibility, in working with materials, such as metals and composites empowers companies to develop long-lasting solutions customized to meet the needs of the electronics sector. This feature aligns with the increasing preference, for customized technology solutions that necessitate enclosures and casings.

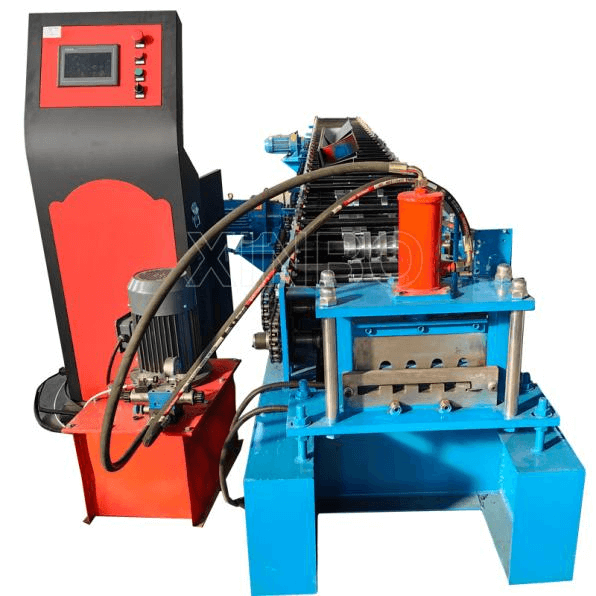

Enhancing Efficiency with XINBO’s Spandrells Machine Solutions

Unique Offerings from XINBO

The spandrells machine, by XINBO, was designed to improve production efficiency and stands out for the features that set it apart from roll forming machines—a must-have, for businesses placing importance on both quality and speed. An impressive feature of this machine is its capability to accommodate custom designs and configurations to meet industry needs and adapt to project sizes. XINBOs cutting-edge solutions combine design elements with engineering principles to help manufacturers enhance performance levels while minimizing operational disruptions.

Customizable Designs and Configurations

The adaptability of spandrells machine enables manufacturers to customize their manufacturing processes for crafting features tailored to the specifications of each project, in the construction sector where designs can differ significantly from one another by leveraging sophisticated design software for rapid adjustments of machine settings, for swift prototyping of spandrels and various parts alike and facilitating seamless workflow efficiency while granting architects and constructors the freedom to bring their imaginative concepts to life without compromising on structural soundness.

Integration with Modern Automation Technologies

Modern automation technologies are vital, in enhancing the functionality of the spandrells machine.XINBO integrates automation software with machine operations to achieve accuracy and consistency, in roll forming procedures. Automation systems can oversee production parameters in time to promptly rectify any discrepancies. These advancements boost efficiency. Cut down labor costs linked to supervision enabling skilled workers to concentrate on key aspects of production.

Case Examples of XINBO’s Innovations

Numerous real-life examples highlight the use of XINBOs spandrell machines, across sectors. For example; Recent undertakings in the field of construction have highlighted the machines ability to craft facade components that strike a balance between visual appeal and structural durability. Collaborations with automobile manufacturers have showcased the machine’s capacity to produce components that meet performance and regulatory requirements seamlessly. Through innovation and customization of machine functionalities, XINBO has solidified its position as a frontrunner in providing tailored roll forming solutions, for industrial demands.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia