Revolutionizing Manufacturing: Roll Forming Machines Explained

Roll forming machines are at the forefront of modern manufacturing, shaping sheet metal with precision and efficiency. Their significance lies in Reinventing Manufacturing Productivity, offering a streamlined process for creating various components. The continuous advancements in technology, such as Additive tooling materials and Hart steel rollers, have revolutionized the industry. As these machines evolve, they play a pivotal role in enhancing production flexibility and reducing costs across different sectors.

The Basics of Roll Forming Machines

Roll forming machines, a cornerstone in modern manufacturing, are innovative tools that shape metal sheets with precision and efficiency. These machines, equipped with cutting-edge technology like Additive tooling materials and robust steel rollers, have transformed the industry.

What Are Roll Forming Machines?

Definition and Function

Roll forming machines are pivotal in bending long strips of metal sheets into various shapes. They play a crucial role in producing consistent profiles for different components. These machines come in diverse sizes, spindle counts, and material thicknesses to cater to specific manufacturing needs.

Key Components

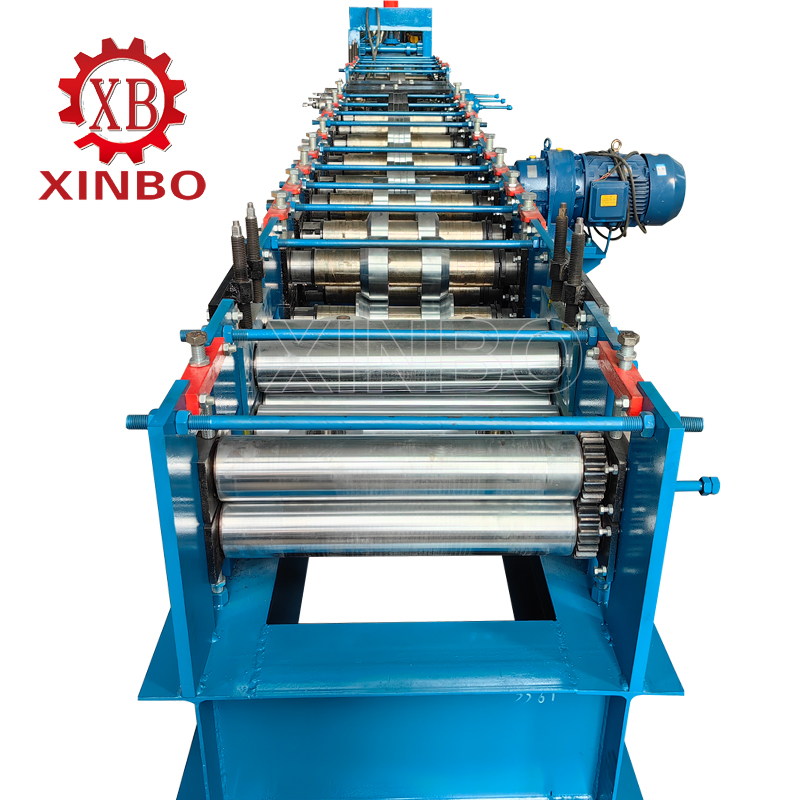

The key components of roll forming machines include hardened steel rollers, a feeding system, and a cutting mechanism. Each component works harmoniously to ensure the seamless transformation of flat metal sheets into engineered shapes.

The Roll Forming Process

Step-by-Step Explanation

The roll forming process involves feeding a continuous sheet of metal through sets of rolls that gradually shape the material into the desired profile. This method allows for precise control over the forming process, ensuring uniformity and accuracy in the final product.

Types of Roll Forming

Roll forming comes in various types such as single-duty machines, standardized models, side-by-side configurations, and double roll formers. Each type offers unique capabilities suited for different applications across industries.

By integrating automation and advanced tooling materials like D2 steel, roll forming machines have become indispensable assets in modern manufacturing processes. Their ability to produce consistent profiles with high precision has revolutionized production methods globally.

Technological Advancements in Roll Forming

Innovations in roll forming technology, particularly the integration of advanced tooling materials and automation, have propelled the industry forward. These advancements are not only enhancing efficiency but also revolutionizing the way manufacturers approach metal shaping processes.

Innovations in Tooling

Advanced Tooling Materials

The introduction of Additive and Digital Advanced tooling materials has significantly improved the precision and durability of roll forming machines. Manufacturers now have access to cutting-edge materials that ensure consistent product quality and longevity. By utilizing these advanced materials, companies can meet the demands of modern manufacturing with enhanced reliability.

Custom Tooling Solutions

Custom tooling solutions are becoming increasingly popular in the roll forming industry. Companies are leveraging Digital Advanced Production Technologies to create tailored tooling solutions that cater to specific production needs. This customization allows for greater flexibility in design and production, ultimately leading to more efficient manufacturing processes.

Automation and AI Integration

Role of Robotics

Automation plays a crucial role in optimizing roll forming operations. The integration of robotics into roll forming machines has streamlined production processes, reducing manual labor and increasing overall efficiency. Robots can perform repetitive tasks with high precision, ensuring consistent output while minimizing errors.

AI in Quality Control

Artificial Intelligence (AI) is transforming quality control in roll forming. By implementing AI algorithms, manufacturers can analyze data in real-time to detect defects or deviations from specifications. This proactive approach to quality control enhances product quality and reduces waste, ultimately leading to cost savings for companies.

Continuous advancements in roll forming technology, such as automated servo-electric roll forming machines, are driving market growth. Technical improvements are expected to propel the industry further by adapting to handle a wider range of materials like advanced high-strength steels and lightweight composites. Roll forming remains a reliable approach to metal shaping ideal for modern applications due to its proven track record and versatility.

Benefits and Applications of Roll Forming

Advantages Over Other Methods

Efficiency and Speed

Roll forming offers unparalleled efficiency and speed in shaping metal sheets. The continuous process ensures a swift transformation from flat sheets to engineered profiles, significantly reducing production time.

The streamlined nature of roll forming machines allows for high-speed operations, making them ideal for mass production without compromising quality.

Cost-Effectiveness

One of the key advantages of roll forming is its cost-effectiveness compared to other metal shaping methods. The continuous process minimizes material waste, leading to cost savings in production.

Additionally, the durability of roll form tooling materials like D2 steel ensures longevity and reduces maintenance costs over time.

Applications in Various Industries

Automotive Industry

Roll forming plays a vital role in the automotive industry by producing components with precise tolerances and complex geometries. From structural parts to trim components, roll-formed products are integral to vehicle manufacturing.

The ability of roll forming machines to work with various metals, including advanced high-strength steels, makes them versatile solutions for automotive applications.

Construction and Infrastructure

In the construction sector, roll forming is widely used for manufacturing building components such as roofing panels, wall studs, and framing systems. The accuracy and repeatability of roll-formed profiles ensure consistency in construction projects.

By utilizing customized tooling solutions, construction companies can achieve specific design requirements while maintaining cost-efficiency in large-scale projects.

Roll Forming Manufacturing Goals

Shorter Lead Times

A primary goal of roll forming manufacturing is to achieve shorter lead times from design to production. The continuous process eliminates the need for multiple setups or secondary operations, streamlining the overall timeline.

By centralizing roll forming processes and tooling storage, manufacturers can further reduce lead times by optimizing workflow efficiency.

Enhanced Production Flexibility

Roll forming offers enhanced production flexibility by accommodating various material thicknesses and profile designs within a single machine setup. This versatility allows manufacturers to adapt quickly to changing market demands.

With advancements in automation technologies and centralized roll forming tooling management systems, manufacturers can enhance their flexibility further while maintaining high precision in production.

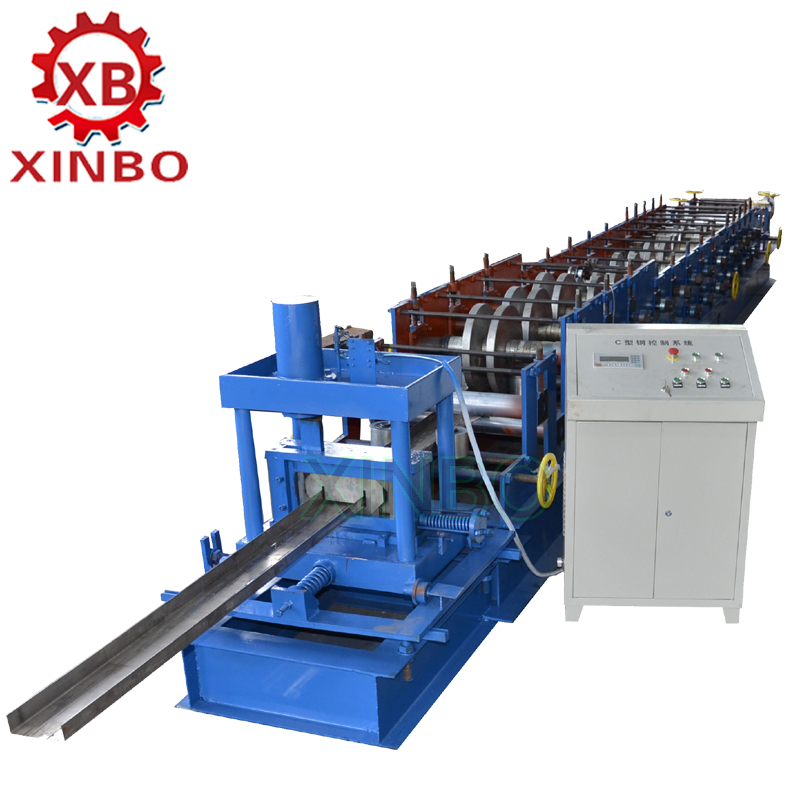

XINBO is a manufacturer that specializes in roll forming machines. These machines are designed to revolutionize the manufacturing process by seamlessly shaping metal sheets into various desired shapes and sizes. XINBO’s roll forming machines are equipped with advanced technology and features that ensure precise and uniform results.

One of the key advantages of XINBO’s roll forming machines is their ability to handle different types of roll forming, such as U-shaped channels, purlins, decking floor panels, and more. These machines are highly adjustable, allowing for easy customization according to specific requirements. They are designed to produce high-quality products that meet the standards of Europe, UK, and Canada.

XINBO’s roll forming machines are known for their efficiency and cost-effectiveness. They are easy to operate and require minimal maintenance, making them a reliable solution for any manufacturing project. Additionally, XINBO’s machines are designed to be loaded into standard containers, saving on logistic costs for international clients.

With a team of professional designers, engineers, and workers, XINBO ensures the quality and innovation of their roll forming machines. Each machine undergoes thorough inspection before shipping to customers, guaranteeing their performance and reliability.

In summary, XINBO’s roll forming machines are at the forefront of revolutionizing the manufacturing industry. Their advanced technology, customization options, and cost-effectiveness make them an ideal choice for businesses looking to enhance their production processes.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia