purlin roll forming machine

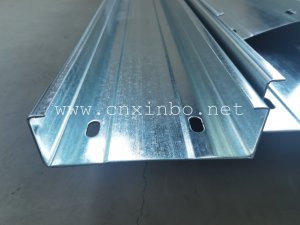

A purlin roll forming machine is a specialized piece of equipment used in the construction industry to manufacture purlins. Purlins are horizontal structural members that support the roof and walls of a building. They are typically made of steel and are essential for providing strength and stability to the structure.

The purlin roll forming machine is designed to produce purlins with consistent dimensions and high precision. It is a fully automated machine that can efficiently produce large quantities of purlins in a short amount of time. The machine works by feeding a coil of steel into the machine, which is then passed through a series of rollers and dies. These rollers and dies shape the steel into the desired profile and cut it to the required length.

One of the key advantages of using a purlin roll forming machine is its versatility. The machine can be easily adjusted to produce different types and sizes of purlins, depending on the specific requirements of the project. This flexibility allows for greater customization and ensures that the purlins produced are perfectly suited for the intended application.

In addition to versatility, the purlin roll forming machine offers several other benefits. Firstly, it eliminates the need for manual labor, reducing the risk of human error and increasing productivity. Secondly, the machine produces purlins with consistent quality, ensuring that every piece is of the same high standard. This is particularly important in construction, where structural integrity is paramount. Lastly, the machine is highly efficient, minimizing waste and maximizing material usage.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia