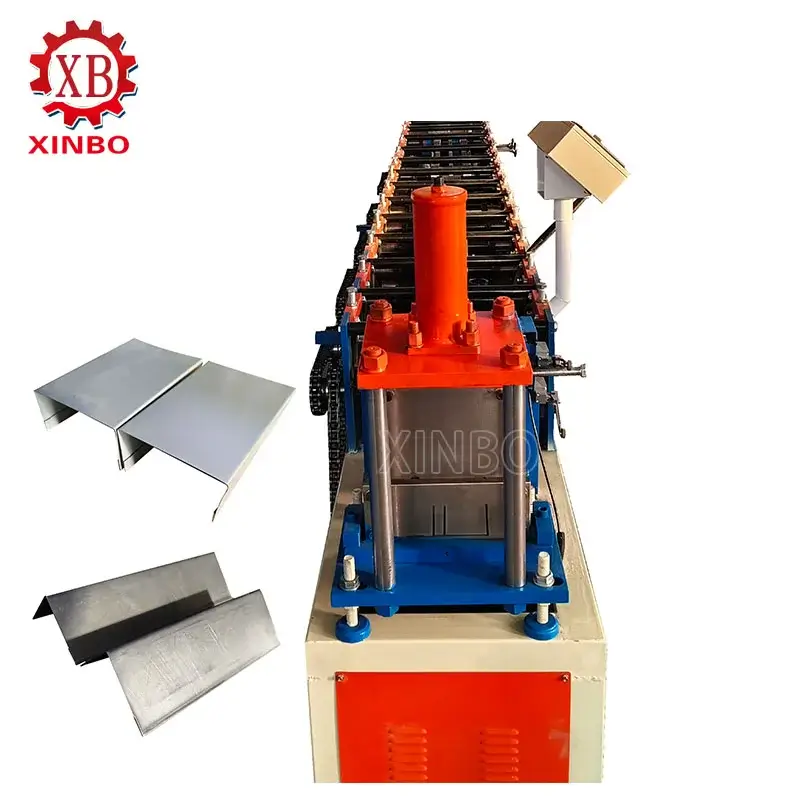

Perfect U L Channel Roll Forming Machine for Every Need: Your Ultimate Guide

In the fast-moving manufacturing world, the right machinery makes a big difference in the production rate, product quality, and cost. Among such essential equipment to work with metal forming, the U L Channel Roll Forming Machine is one of the perfect examples, showing versatility in different working aspects. Whether you are dealing with construction, automotive, or even steel, this machine will change the way you do business. This blog will explore the key benefits, features, and specifications of this machine, and why Xinbo‘s U L Channel Roll Forming Machine is the best for bulk buying for business.

Why Choose a U L Channel Roll Forming Machine?

The continuous bending process in roll forming involves the passing of metal strips through a series of rollers, which progressively bend the strip into desired profiles. In the case of U and L channels, these machines are capable of operating a wide range of materials, from PPGI to GI, and thus fabricate channels to exact specifications. The Versatile U L Channel Roll Forming Machine is ideal for any wholesale company that aims to fulfill the demand for high-volume production.

The Versatility of U and L Channel Production

A U L Channel Roll Forming Machine is special in its kind, as it can perform the production of two types of shapes: U and L channels. These forms have a wide application in framing to structural components in construction, automobiles, and industry in general. The machine is designed to handle a variety of channel sizes, making it an important asset for businesses with different product requirements. Here are reasons why these machines are significant to ensure high-quality production:

Personalization:The adjusted rollers allow easy alteration of channel dimensions according to various project needs.

Precision:This machine produces uniform shapes of channels with very high accuracy, minimizing defects in the final products.

Speed:High speed during production allows manufacturers to complete big orders in relatively little time, reducing lead times while increasing productivity.

Key Features of a U L Channel Roll Forming Machine

The type of roll forming machine that one decides to invest in should have the features that would help enhance the production process. Here are the distinguishing features of the Versatile U L Channel Roll Forming Machine:

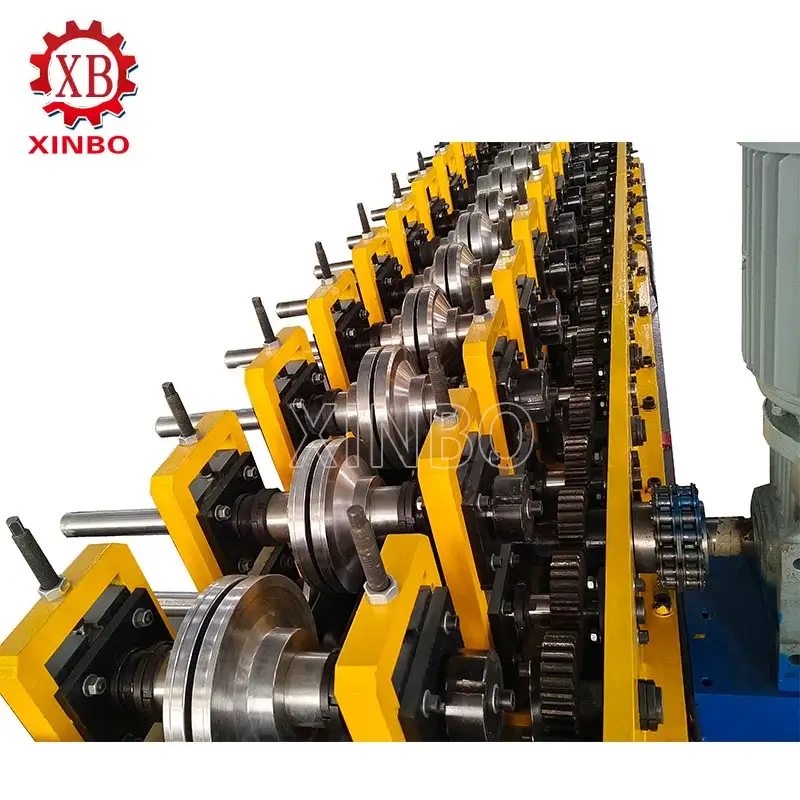

1. Adjustable Rollers for Multiple Dimensions

The adjustable rollers are an important part of the U L Channel Roll Forming Machine, which enables the making of channels in different sizes and thicknesses. From a narrow ‘U’ channel for light-duty purposes to a broader one for more robust applications, this machine can easily adapt to your needs.

2. High-Speed Production for Increased Efficiency

This machine is designed with efficiency in mind and offers high-speed operation that allows for production speeds of up to 15 meters per minute. Faster production means more output in less time, which is crucial in meeting tight deadlines without compromising on quality.

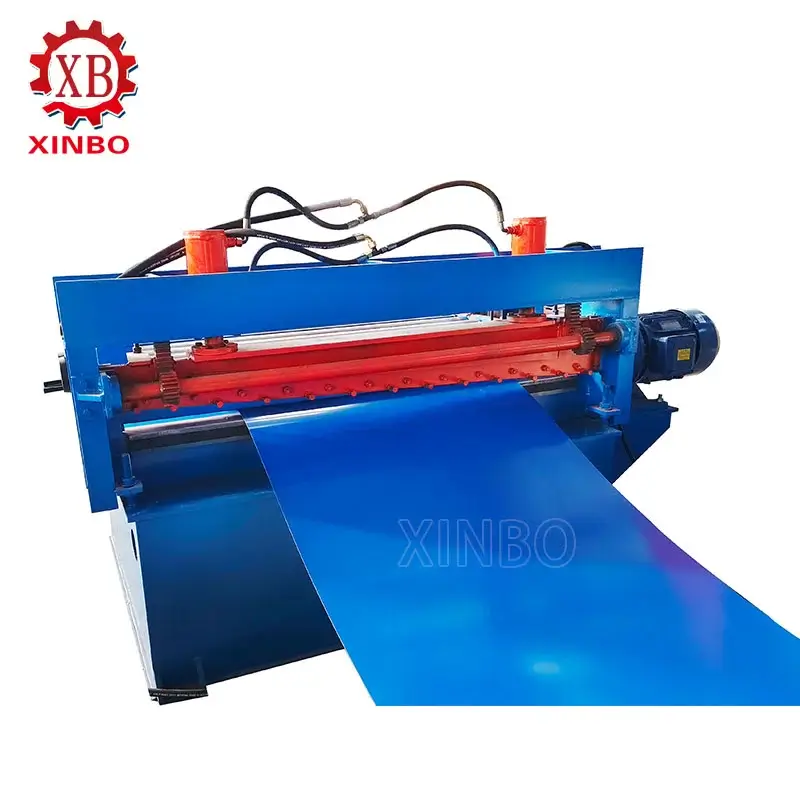

3. Hydraulic Profile Cutting for Clean Edges

The hydraulic profile cutting system helps to smoothen out and clean the cut at the end of every production cycle, thus reducing additional works in finishing. This attribute enhances both the aesthetic and functional quality of the channel.

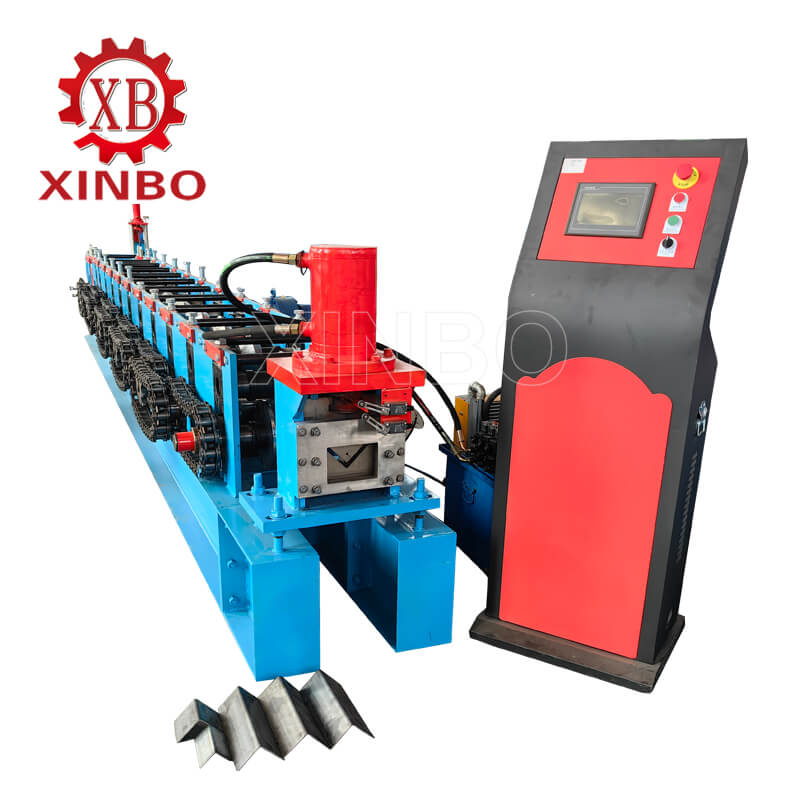

4. PLC Control System for Easy Operation

The PLC system is integrated with the button and touch-screen interface, hence making operation quite simple and user-friendly. Even less-experienced operators can quickly learn how to run the machine in such a way that it saves time for training and reduces any chances of operational errors.

5. Customized Specifications

The U L Channel Roll Forming Machine can be highly customized. From material thickness to the width and length of the processing, you can tailor this machine for your exact production requirements. Whether producing U channels with a thickness of 0.6mm or in any other custom size, this machine can manufacture them all.

The Perfect Machine for Businesses

The benefits of the Versatile U L Channel Roll Forming Machine for any wholesaler business are very attractive, whether in construction, automotive, or steel. To begin with, the machine offers an opportunity to make multiple types of channels, dimension adjustment is easy and quick, and high-speed production keeps the wholesalers competitive in the market. Let’s look at how this machine can improve your bottom line.

Cost-Effective Production

Wholesale businesses rely on cost efficiency. The ability to process different channel shapes and sizes with only one machine will minimize various investments in different equipment. Capable of producing large quantities in a very short period of time with low operational costs, the U L Channel Roll Forming Machine will save you money with increased production capability.

Increased Profitability

Increased production rates and a reduction of labor costs naturally increase profitability. With this kind of high-performance machinery, you can certainly meet bulk orders effectively, thereby enhancing your output without sacrificing quality.

Consistency and Quality Control

With its precise control and customizable settings, the U L Channel Roll Forming Machine ensures consistent product quality. Each channel produced will not deviate from specifications and thereby reduce waste or reworks.

Specifications of the Versatile U L Channel Roll Forming Machine

Here is an overview of the technical specifications that make this machine robust and versatile to the needs of the wholesale supplier:

Processing Material:PPGI/GI coils

Input Width:Customized

Formed Width:According to drawing/need

Processing Thickness:Standard 0.6mm (customized)

Frame Style:Square pipe welded

Material of Rollers:45# steel with heat treatment and hard chroming

Diameter of Shaft:40mm

Production Speed:Standard: 0–15m/min (customized)

Roller Driven:Decelerating Motor + China Transmission

Cutting Model:Hydraulic Profile Cutting

Length Measurement:Encoder

Control Style:PLC

Operation Model:Button + Touch Screen

Total Power:4+4KW (customized)

Voltage:380V, 50Hz, 3-phase (or buyer’s request)

Why Choose Xinbo for Your U L Channel Roll Forming Machine?

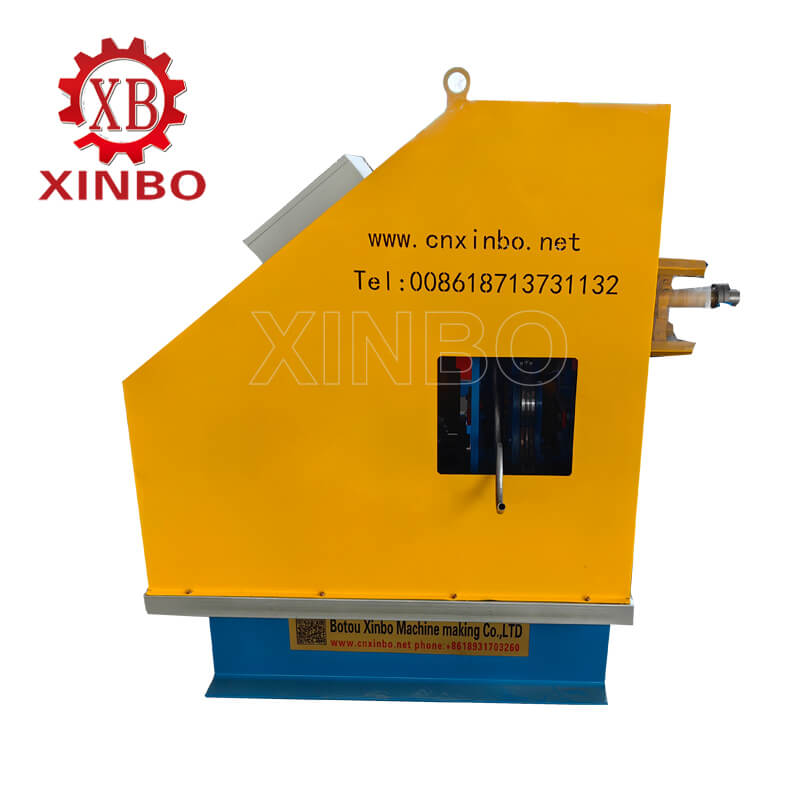

While searching for a supplier of U L Channel Roll Forming Machines, it is important to find a manufacturer that can provide quality machines, good prices, and great customer service. Xinbo is one of the most well-known companies in the roll forming industry due to its high-quality machines manufactured according to international standards.

Xinbo’s Expertise and Custom Solutions

Xinbo was founded in 2014, but the team has over a decade of experience in the manufacturing of metal shaping and roll-forming machines. The company’s approach to business is centered around providing customized solutions to fit each client’s needs. Whether your channels require a different size or have special material requirements, the engineers at Xinbo can design the perfect solution for your needs.

Quality and Reliability

All Xinbo machinery, including the U L Channel Roll Forming Machine, undergo three rigorous quality inspections before shipment. This ensures that the machine is of high standards and will serve you well within your facility.

Fast Delivery Times

With in-house design and machining, Xinbo ensures timely delivery of your machines so that you can stay right on schedule with your production.

Excellent Customer Support

Xinbo provides full after-sales support, including assisting in installation, training operators, and maintenance services. The professional customer service team at Xinbo guides you through every step in the production process.

Get in Touch with Xinbo

Looking for the Versatile U L Channel Roll Forming Machine to upgrade your production line? Look no more than Xinbo! With competitive prices, super quality, and customizing as per requirement, Xinbo can definitely be your reliable supplier for roll forming machines.

To get in touch with Xinbo for inquiries or requesting a quotation, please use the following:

Email:serena@cnxinbo.net

Phone:+86 18713731132

WhatsApp:+86 18713731132

Conclusion

It is wise to invest in a U L Channel Roll Forming Machine from wholesale suppliers when the investment has to be versatile, of high quality, and cost-effective. With a machine from Xinbo, you can expect fast production speeds, great customizability, and very durable machinery. Increase your business’s production today and stay competitive with Xinbo’s Versatile U L Channel Roll Forming Machine. Contact Xinbo today for more information!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia