Optimizing Roll Forming Machine Operation for Molding Precision and Efficiency

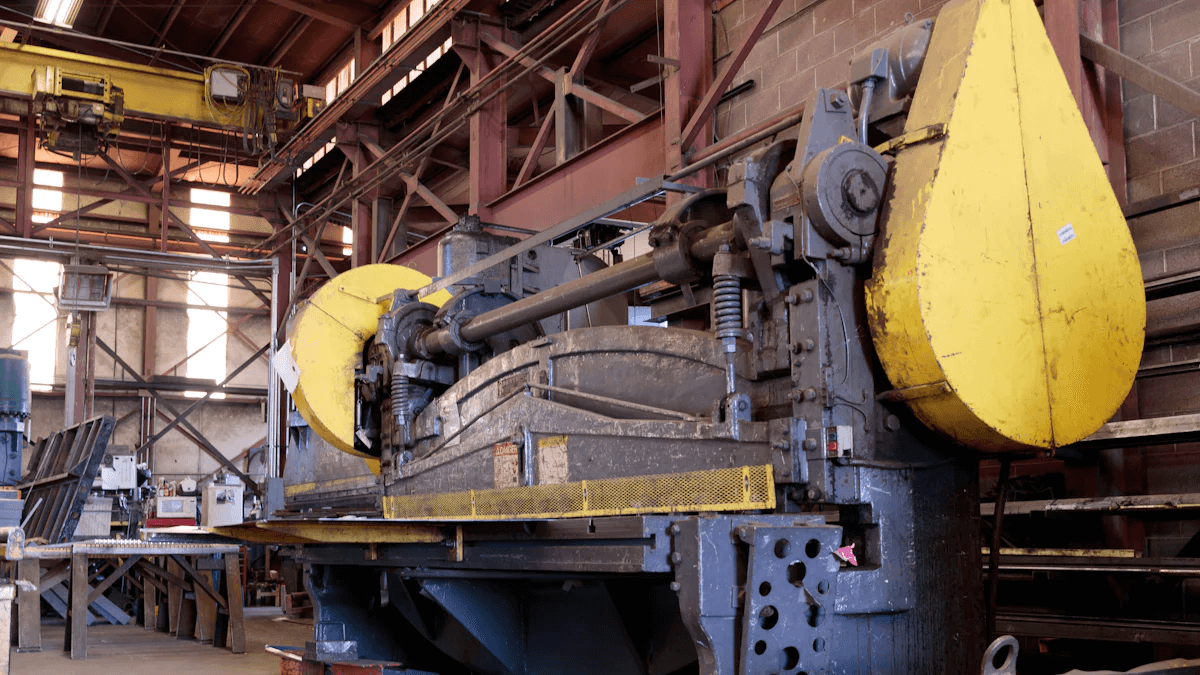

Understanding Roll Forming Machines

Roll forming machines are a crucial part of modern manufacturing, revolutionizing the way sheet metal is transformed into precise and complex shapes. The operation of these machines involves a series of components and functionalities that contribute to their efficiency and accuracy.

The Basics of Roll Forming Machine Operation

Roll forming machines consist of several key components that work together to shape metal coils into desired profiles and geometries. These components include rollers, guides, entry and exit stands, and cut-off systems. The rollers play a fundamental role in shaping the metal, while the guides ensure proper alignment throughout the process. Additionally, the entry and exit stands facilitate the smooth movement of the material, while the cut-off systems enable precise cutting of the formed metal into desired lengths.

The role of roll forming in modern manufacturing cannot be overstated. As demand for customized metal components continues to rise across various industries, roll forming machines have become indispensable for efficiently producing these components. The automotive industry, in particular, has been a major driver of the increased demand for roll forming machines due to its need for lightweight yet durable products.

The Evolution of Roll Forming Technology

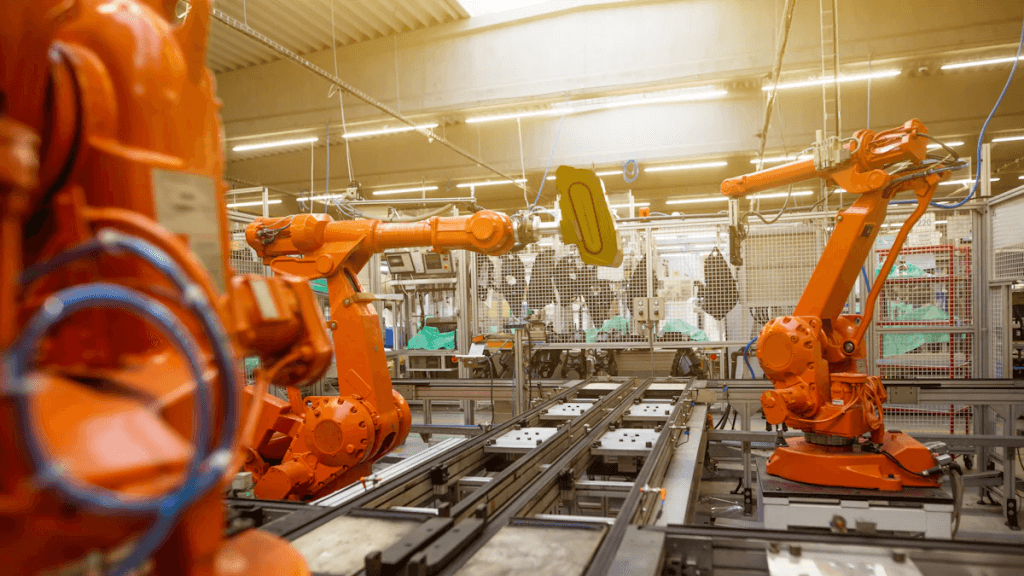

From manual operations to highly automated systems, roll forming technology has undergone significant advancements over the years. Technological progresses such as automated servo-electric roll forming machines have streamlined the metal forming process while maintaining high levels of precision and security. These advancements have also led to an increase in market size due to factors such as automation, material advancements, and the rising need for lightweight and durable products in various industries.

Recent innovations in roll forming machines have further propelled their significance in modern manufacturing. Advanced robotic roll forming machines utilize control units and sensor technology for quality control and tool changeovers, enhancing overall operational efficiency.

Enhancing Precision in Roll Forming Operations

Roll forming machines are essential for producing complex metal parts with high accuracy. Achieving precision in roll forming operations involves several key factors and technological advancements that contribute to the overall quality and consistency of the formed products.

Key Factors Affecting Precision

Material Quality and Preparation

The quality of the material used in roll forming significantly impacts the precision of the final product. Consistent material properties throughout the process are crucial for maintaining uniformity and achieving high accuracy. Careful control of material properties, including thickness and composition, is essential to minimize variations and ensure precise shaping.

Machine Alignment and Calibration

Proper alignment of forming rolls is critical for achieving precision in roll forming operations. Misalignment can lead to irregularities in the formed profiles, affecting their dimensional accuracy. Additionally, regular calibration of roll forming machines is necessary to maintain optimal performance and ensure consistent product quality.

Technological Advancements for Improved Precision

Computer-Controlled Systems

The integration of computer-controlled systems has revolutionized precision in roll forming operations. These advanced systems allow for precise control over various parameters such as roller pressure, speed, and material feed, resulting in highly accurate shaping of metal profiles. By leveraging computer-controlled technology, manufacturers can achieve tight tolerances and produce intricate profiles with exceptional precision.

Real-Time Monitoring and Adjustments

Real-time monitoring systems play a crucial role in ensuring precision during roll forming processes. These systems enable operators to monitor key metrics such as material thickness, profile dimensions, and machine performance while making real-time adjustments as needed. By continuously monitoring the process parameters and making immediate adjustments, manufacturers can maintain consistent product quality and minimize deviations from desired specifications.

Roll forming machines market size was valued at USD 472.6 million in 2022 and is expected to expand at a CAGR of 4.4% during the forecast period, reaching USD 756.7 million by 2032. The main findings of reports indicate a growing demand for high-precision roll forming machines due to their ability to produce complex metal parts with high accuracy.

In general, scholars have used a combination of the finite element method and experimental methods to analyze the impact of various factors on profile roll forming. Some advantages of roll forming machines include high production efficiency, precise and consistent shaping, minimal material waste, and the ability to create complex profiles.

Boosting Efficiency with Roll Forming Machines

Roll forming machines play a pivotal role in enhancing efficiency across various manufacturing processes. By streamlining the roll forming process and leveraging high-strength materials, manufacturers can achieve significant improvements in productivity and product quality.

Streamlining the Roll Forming Process

Optimizing Material Handling

Efficient material handling is essential for maximizing the throughput of roll forming machines. Implementing automated material handling equipment at the entry and exit points of the roll forming line can significantly increase production efficiency. Wholesale European standard high-quality scaffold systems and fittings for construction projects are available, offering robust solutions for material handling in roll forming operations. By integrating these advanced material handling systems, manufacturers can streamline the flow of raw materials, minimize manual intervention, and reduce overall processing time.

Reducing Downtime through Preventative Maintenance

Proactive maintenance strategies are crucial for minimizing downtime and ensuring continuous operation of roll forming machines. Investment and financial services firms have announced the acquisition of roll forming equipment makers, emphasizing the significance of preventative maintenance in optimizing machine performance. Manufacturers can implement routine maintenance schedules encompassing daily, weekly, and monthly tasks to identify potential issues early on and prevent unexpected breakdowns. This approach not only reduces unplanned downtime but also extends the lifespan of critical machine components, contributing to long-term operational efficiency.

Leveraging High-Strength Materials

Benefits of High-Strength Materials

The utilization of high-strength materials offers several advantages in roll forming operations. Superior Roll Forming Case Study highlights how high-strength materials contribute to enhanced product durability and structural integrity. These materials enable manufacturers to produce lightweight yet robust components that meet stringent performance requirements across diverse industries. Additionally, leveraging high-strength materials leads to reduced material consumption while maintaining exceptional mechanical properties, resulting in cost savings and sustainable manufacturing practices.

Challenges and Solutions

While working with high-strength materials presents numerous benefits, it also introduces unique challenges during the roll forming process. Roller Die’s roll forming system case study emphasizes the importance of precise calibration and tooling adjustments when processing high-strength materials to ensure dimensional accuracy and profile consistency. To address these challenges, manufacturers can invest in advanced tooling technologies designed specifically for high-strength alloys, enabling precise shaping while mitigating material waste.

Roll formers continue to evolve as they adapt to handle high-strength materials efficiently while maintaining precision throughout the process.

Best Practices for Roll Forming Machine Maintenance

Roll forming machines are intricate pieces of equipment that require regular maintenance to ensure optimal performance, prevent costly repairs, and prolong their operational lifespan. By adhering to a comprehensive maintenance checklist and promptly addressing common issues, manufacturers can maximize the efficiency and reliability of their roll forming operations.

Routine Maintenance Checklist

Daily, Weekly, and Monthly Tasks

Routine maintenance tasks for roll forming machines encompass a range of activities aimed at preserving the machine’s functionality and structural integrity. Lubricating moving parts, inspecting and replacing worn tooling, and checking for alignment issues are essential daily tasks that contribute to the smooth operation of roll forming machines. Weekly tasks may involve conducting thorough cleanliness checks to ensure effective operation free from impurities. Monthly maintenance activities often include more in-depth inspections of critical components such as rollers, guides, and cutting systems to identify any signs of wear or misalignment.

Importance of Regular Inspections

Regular inspections are critical for identifying potential issues early on and preventing unexpected breakdowns that can disrupt production schedules. Completing routine maintenance not only ensures consistent product quality but also contributes to safer performance, saving money from potential repairs while improving end product quality.

Troubleshooting Common Issues

Identifying and Addressing Problems Early

Early identification of common issues such as irregularities in formed profiles, unusual noises during operation, or fluctuations in material feed is crucial for maintaining the precision and efficiency of roll forming machines. Manufacturers should empower operators with the knowledge to recognize these signs and take immediate corrective actions when necessary.

When to Seek Professional Help

While routine maintenance tasks can address many common issues, there are instances where professional assistance is required. Manufacturer’s service teams provide specific guidance for machines critical to breakdown-avoidance. Seeking professional help for complex troubleshooting or major component replacements ensures that roll forming machines continue to operate at peak performance levels.

Roll formers continue to evolve as they adapt to handle high-strength materials efficiently while maintaining precision throughout the process.

Xinbo Machine Making Co. Ltd, established in China since 2014, is a renowned manufacturer of roll forming machines. These machines are designed with innovative technology to meet the needs of customers globally, particularly in Europe, the UK, and Canada.

Xinbo offers a variety of roll forming machines, each designed to shape metal sheets into specific forms. The U channel rolling forming machine, for instance, is equipped with advanced technology that enables it to roll metal sheets into U-shaped channels of different sizes and thicknesses. It is highly adjustable, allowing for easy customization according to specific requirements.

Conclusion

The Future of Roll Forming Machines

As companies continue to invest in advanced technology to enhance their production processes, the market for roll forming machines is witnessing significant growth. The demand for customized, lightweight components is a driving force behind the adoption of high-precision roll forming machines, leading to a steady increase in market size. This positive outlook reflects the increasing need for precision-engineered products in various industries such as automotive, aerospace, and construction.

Ongoing Developments and Potential

The present outlook of the High Precision Roll Forming Machine market is positive, with advancements in technology playing a pivotal role in shaping its future. Technological progresses have paved the way for the development of highly automated systems that offer unparalleled precision and efficiency. Manufacturers are embracing innovative solutions that enable them to meet the evolving demands of modern manufacturing while maintaining exceptional levels of accuracy. These ongoing developments underscore the potential for further advancements in roll forming technology, positioning it as a key enabler of efficient and precise metal shaping processes.

Embracing Innovation for Continued Success

Embracing innovation will be crucial for the continued success of roll forming machines in meeting the dynamic needs of diverse industries. As technological advancements continue to drive progress in roll forming technology, manufacturers must remain at the forefront of innovation to capitalize on emerging opportunities. By leveraging cutting-edge solutions such as computer-controlled systems and real-time monitoring technologies, manufacturers can ensure that their roll forming operations remain at the forefront of precision and efficiency.

In conclusion, the future holds immense potential for roll forming machines as they continue to evolve alongside technological advancements. Embracing innovation will be essential for manufacturers seeking continued success in delivering high-precision metal components across various industrial sectors.

Roll formers are poised to play an increasingly vital role in modern manufacturing processes by offering unmatched precision and efficiency through ongoing technological developments.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia