Optimizing Efficiency with Steel Roof Panel Three Layer Roof Machines

Introduction to Steel Roof Panel Efficiency

In the construction industry, the durability and performance of roofing materials are critical factors that significantly influence both the quality and longevity of structures. Steel roof panels have emerged as a preferred choice due to their resilience and efficiency. The implementation of advanced manufacturing technologies, particularly through three-layer roof machines, has optimized the production of these steel roof panels, enabling higher efficiency rates and improved product standards. As the demand for effective roofing solutions continues to rise, it becomes crucial to understand how three-layer roof machines can enhance the overall efficiency of steel roof panel manufacturing.

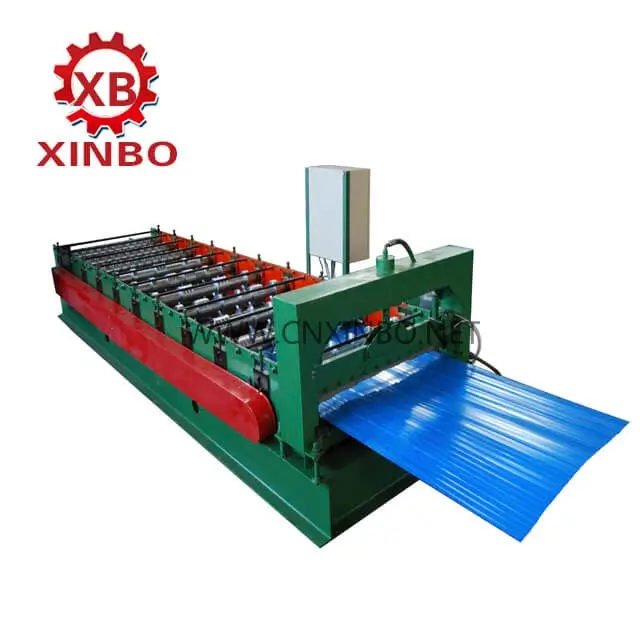

Overview of Three-Layer Roof Machines

Design and Construction

Three-layer roof machines are engineered with precision to produce steel roof panels that meet specific industry requirements. These machines integrate several components that work harmoniously to form durable roofing products. The design encompasses a series of rolls that shape the steel sheets into desired profiles, ensuring consistency in thickness and profile width. Moreover, the construction of these machines employs high-quality materials that not only contribute to the durability of the machines but also enhance the quality of the panels produced.

Key Functionalities

The core functionality of three-layer roof machines lies in their ability to produce multi-layered panels in a single pass. This efficiency is achieved through a coordinated operation where three separate layers are simultaneously processed. The first layer generally comprises a base steel layer, followed by insulation and a protective top layer, contributing to enhanced thermal efficiency and structural integrity. Moreover, the machines are designed to minimize material waste and production time, positioning them as essential tools in modern manufacturing.

Advantages of Using Steel Roof Panel Three-Layer Machines

Enhanced Production Speed

One of the most significant benefits of three-layer roof machines is their ability to enhance production speed. By processing several layers simultaneously, manufacturers can significantly reduce the turnaround time for roofing projects. This increased speed not only allows for meeting tight deadlines but also maximizes output without compromising on quality. The efficiency of these machines is critical in a competitive market, where timely delivery often determines project success.

Quality Consistency in Panels

Quality consistency is another key advantage offered by three-layer roof machines. These machines are equipped with advanced technologies that ensure uniformity in the panels produced. This includes maintaining consistent dimensions, weight distribution, and adherence to industry standards. With the ability to continuously monitor and adjust production parameters, these machines assure manufacturers of high-quality steel roof panels that meet customer expectations and regulatory compliance.

Cost-Efficiency

Investing in three-layer roof machines results in significant cost efficiencies for manufacturers. The reduced production time not only leads to lower labor costs but also maximizes resource utilization, which translates into savings on raw materials. In addition, the longevity and durability of steel roof panels reduce the likelihood of future repairs and replacements, offering long-term financial benefits to both manufacturers and consumers alike.

Features of Xinbo Machine Making Co. Ltd.

History and Experience

Xinbo Machine Making Co. Ltd. brings a wealth of experience in the manufacturing of three-layer roof machines, making it a notable player in the industry. With years of dedicated service, the company has established itself as a reputable manufacturer, known for its commitment to quality and innovation. The expertise accumulated over the years enables Xinbo to understand and anticipate the needs of the market, thereby offering customized solutions that meet diverse customer requirements.

Technological Innovation

Advanced Manufacturing Techniques

At the forefront of Xinbo’s success is its dedication to technological innovation. The company continually invests in advanced manufacturing techniques, ensuring that its machines are equipped with the latest technological advancements. This commitment not only enhances the efficiency of their machines but also translates into superior quality for the steel roof panels produced. By prioritizing innovation, Xinbo remains competitive in a rapidly evolving market.

Integration of Automation

The integration of automation in Xinbo’s three-layer roof machines epitomizes their commitment to efficiency and production excellence. By automating various processes, the company minimizes human error and maximizes precision in panel production. Automation also allows for better data collection and analysis, providing manufacturers with valuable insights to further optimize their operations.

Global Reach and Clientele

Xinbo Machine Making Co. Ltd. boasts an impressive global reach, serving a diverse clientele across various countries. This broad customer base not only highlights the quality of their machines but also emphasizes the trust placed in Xinbo by industry professionals. Their ability to cater to international markets showcases their flexibility and adaptability in meeting different regulatory and market standards throughout the world.

Technical Specifications of Three-Layer Roof Machines

Structural Characteristics

Material Specifications

The structural integrity of three-layer roof machines is paramount in ensuring reliable performance. Xinbo utilizes high-grade steel and other robust materials in the construction of their machines, significantly enhancing their durability and resilience. The materials used are selected based on their ability to withstand extreme operational conditions, ensuring that the machines remain functional and efficient over time.

Design Flexibility

Three-layer roof machines from Xinbo offer design flexibility to suit various production requirements. The machines can be customized based on the specific needs of clients, allowing for modifications that cater to different roofing specifications. This adaptability enables manufacturers to produce a wide range of steel roof panels, thereby expanding their product offerings in a competitive market.

Operational Mechanisms

Control Systems

The operational mechanisms of three-layer roof machines are equipped with sophisticated control systems that enable precise monitoring and adjustments throughout the production process. These systems allow operators to input desired settings and receive real-time feedback, ensuring that the production remains consistent and optimized. This level of control ensures that manufacturers can produce high-quality steel roof panels while minimizing wastage.

Energy Efficiency

Energy efficiency is a critical consideration in modern manufacturing processes. Xinbo’s three-layer roof machines are designed with energy-saving features that significantly reduce power consumption during operations. By optimizing energy use, manufacturers not only reduce their operational costs but also contribute to sustainability efforts within the industry. This focus on energy efficiency positions Xinbo as a responsible manufacturer committed to environmental stewardship.

Comparison with Traditional Roofing Machines

Time Efficiency

When comparing three-layer roof machines to traditional roofing machines, time efficiency emerges as a pivotal factor. Traditional methods often require multiple passes to produce layered materials, resulting in longer production timelines. In contrast, three-layer roof machines are specifically designed to create multi-layered steel roof panels in a single continuous flow, drastically reducing manufacturing time. This efficiency not only enhances overall productivity but also allows companies to meet tight project deadlines without sacrificing quality.

Labor Requirements

Labor requirements for three-layer roof machines also present a significant advantage over traditional roofing machines. Traditional machines often necessitate a larger workforce to monitor, manage, and operate various distinct functions during the production process. Conversely, the integration of automation in three-layer roof machines streamlines operations, allowing a smaller, more skilled team to oversee the manufacturing. This reduction in labor needs not only cuts down on personnel costs but also mitigates risks associated with human error in production.

Output Quality

The output quality of steel roof panel production also differentiates three-layer roof machines from their traditional counterparts. Traditional machines may struggle with maintaining uniformity in size and thickness due to their multi-step processes. However, three-layer roof machines are engineered to ensure consistent quality through advanced control systems that monitor production parameters in real time. This capability contributes to high standards in thickness, profile, and overall performance of the steel roof panels produced, meeting stringent industry regulations and customer expectations.

Application Scenarios for Steel Roof Panel Three-Layer Machines

Residential Construction Projects

In residential construction, the demand for durable and efficient roofing solutions continues to grow. Three-layer roof machines cater to this need by providing high-quality steel roof panels that enhance thermal insulation and weather resistance. Homebuilders benefit from the speed and consistency these machines offer, allowing for faster construction timelines without compromising on quality. Additionally, the aesthetic versatility of steel roof panels produced through these machines enables homeowners to choose from a range of designs that complement various architectural styles.

Industrial and Commercial Applications

The industrial and commercial sectors also greatly benefit from the use of three-layer roof machines. Industries often require robust roofing systems that can withstand heavy loads and harsh environmental conditions. By producing steel roof panels with enhanced structural integrity and durability, these machines meet the stringent requirements of warehouses, manufacturing facilities, and commercial buildings. Furthermore, the quick turnaround provided by three-layer machines is advantageous for large-scale construction projects, assisting companies in meeting both deadlines and budget constraints.

Future Trends in Roofing Technology

Advancements in Material Science

Looking ahead, advancements in material science are bound to influence the future of roofing technology significantly. As researchers explore new alloys and composite materials, three-layer roof machines will be able to produce even higher-performing steel roof panels. Innovations in energy-efficient coatings and treatments will enhance the longevity and functionality of panels, making them even more appealing to consumers. These advancements also promise to integrate sustainability into roofing applications, aligning with global efforts toward reduced environmental impact.

Emerging Market Needs

Emerging market needs will also shape the development of three-layer roof machines and steel roof panels. As urbanization continues to rise, the demand for efficient and cost-effective roofing solutions is expected to increase. Additionally, with more emphasis on sustainable construction practices, there will be a push for roofing materials that not only perform well but are also produced through eco-friendly processes. Three-layer roof machines, by their efficient production capabilities, are positioned to respond to these growing demands, adapting to the evolving requirements of the construction industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia