Metal Roll Forming System: A Key Technology to Help Manufacturing Transformation and Upgrading

With the continuous development of the global economy, the manufacturing industry, as an important pillar of the national economy, is facing unprecedented pressure of transformation and upgrading. In this article, metal roll forming system, with its unique advantages and wide range of applications, is gradually becoming one of the key technologies to promote the transformation and upgrading of the manufacturing industry.

Basic principle and technical characteristics of metal roll forming system

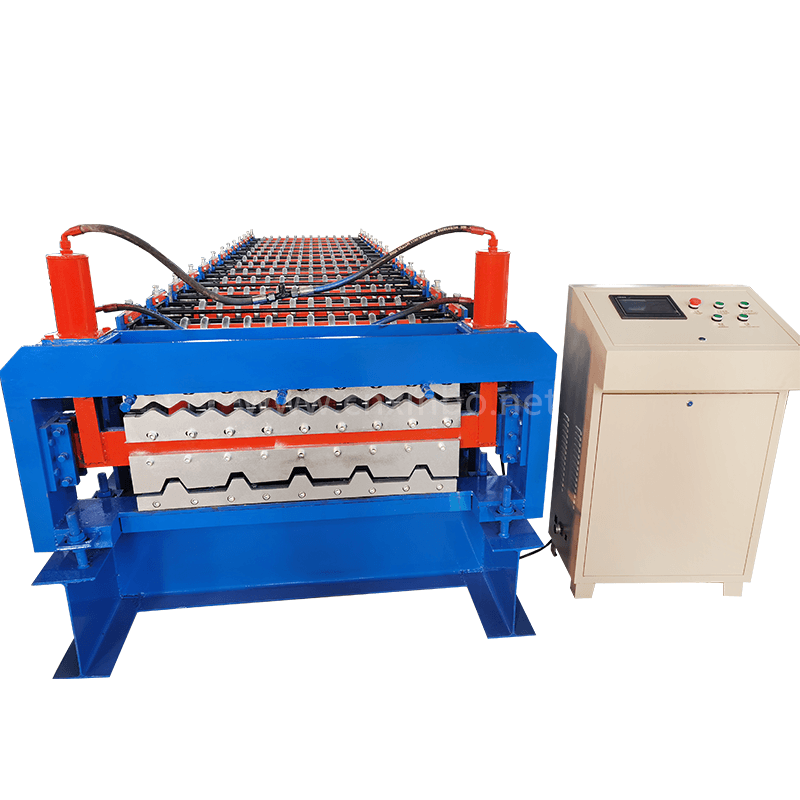

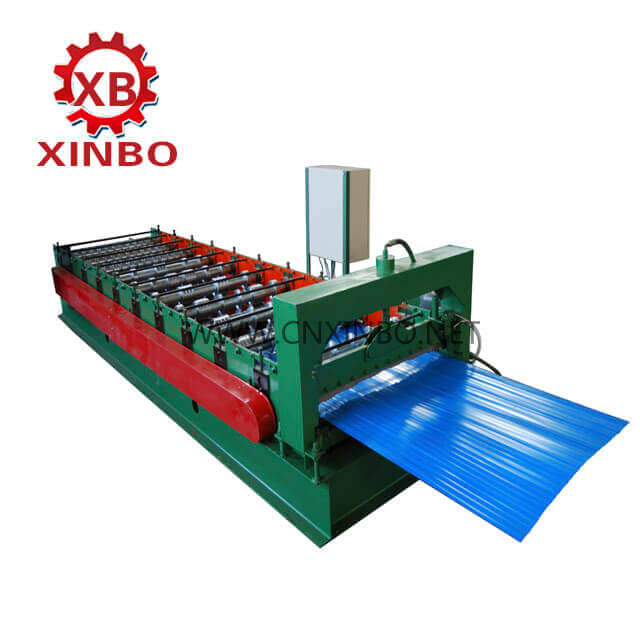

Metal roll forming system is a use of rolling pressure to make plastic deformation of metal materials, so as to obtain the required shape and size of the advanced processing technology. The basic principle is to apply high pressure and friction to the metal material through the rollers, so that its plastic flow and deformation occurs under the constraint of the mold. Compared with traditional cutting processing, metal roll forming system has significant technical characteristics.

First of all, the metal roll forming system can realize efficient and high-precision processing. Since the metal material is plastically deformed under the constraint of the mold during the rolling process, higher dimensional accuracy and surface quality can be obtained. In addition, the material flow in the roll forming process is continuous, avoiding the cutting force impact and thermal influence in traditional cutting processing, thus reducing processing deformation and residual stress.

Secondly, metal roll forming system has the advantages of high material utilization and low energy consumption. In the rolling process, the metal material only plastic deformation without cutting waste, so the material utilization rate is very high. At the same time, the roll forming process does not require a large amount of cutting fluid for cooling and lubrication, reducing energy consumption and environmental pollution.

Finally, the metal roll forming system also has good adaptability and flexibility. By replacing different molds and adjusting process parameters, it is possible to process metal parts of different materials, shapes and sizes. This flexibility and adaptability makes the metal roll forming system has a wide range of application prospects in the manufacturing industry.

Metal roll forming system in the manufacturing industry in the field of application

Metal roll forming system with its unique advantages and a wide range of applications in the manufacturing industry plays an important role. The following are some typical application areas:

Automobile manufacturing industry: automobile manufacturing industry is one of the main application areas of metal roll forming system. Automotive parts such as engine block, cylinder head, crankcase, etc. can be produced by roll forming technology. Roll forming technology can not only improve the accuracy and surface quality of the parts, but also reduce material consumption and production costs, which helps to achieve automotive lightweight and energy saving and emission reduction.

Aerospace: The aerospace industry has extremely high requirements for material performance and part precision. Metal roll forming technology can produce high-precision, high-strength aerospace parts, such as engine blades, turbine disks and so on. At the same time, roll forming technology can also reduce the residual stress of the parts, improve the fatigue life and safety of the parts.

Power equipment manufacturing industry: the power equipment manufacturing industry requires high precision and reliability of metal parts. Metal roll forming technology can produce high-quality power equipment parts, such as generator rotors, transformer cores and so on. Roll forming technology can not only improve the accuracy and reliability of parts, but also reduce production costs and shorten the production cycle.

Key role of metal roll forming system to help the transformation and upgrading of the manufacturing industry

Metal roll forming system as one of the key technologies to promote the transformation and upgrading of the manufacturing industry, with the following aspects of the key role:

Improve production efficiency: metal roll forming technology is characterized by high efficiency and high precision, which can significantly improve production efficiency and shorten the production cycle. This helps manufacturing enterprises to increase production, reduce costs and enhance market competitiveness.

Promote energy conservation and emissions reduction: Steel roll technology has the advantage of low input and energy consumption, which contributes to energy efficiency and reduced waste in the manufacturing process This energy saving and emission reduction , is inline with the current societal trend of green development, and helps to promote manufacturing to achieve sustainable development

Enhancing product quality: Metal roll fabrication technology can achieve dimensional accuracy and high surface quality, reducing processing deformation and residual stress. This helps to improve product efficiency, extend product life, and increase customer satisfaction.

Conclusion

As an advanced metalworking process, metal roll foaming machine plays an important role in the transformation and improvement of the manufacturing process. In the future, due to advances and innovations in technology, as well as changes and developments in the market, the steel leather industry will face new opportunities and challenges. Only through continuous innovation, improving product quality and efficiency, reducing production costs, and strengthening employee training and standards, can we drive steel roll fabrication system adoption encourage greater engagement and growth in the industry and actively support product reform and infrastructure upgrades.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia