Maximizing Efficiency with Metals Used in Sheet Metal Forming Machines

Factors to Consider When Choosing a Metal

Strength and Flexibility Requirements

Strength and flexibility are pivotal factors when selecting a metal for sheet metal forming. Different applications require specific mechanical properties to ensure optimal performance. For example, automotive and construction industries often demand high tensile strength to withstand substantial loads and stresses. Steel, with its robust strength, is typically favored in these segments. Conversely, applications such as aerospace and electronics might prioritize flexibility and weight reduction, making aluminum a suitable choice due to its lightweight and moderate strength. Balancing strength and flexibility ensures the end product meets performance standards without unnecessary bulk or rigidity.

Corrosion Resistance Needs

Corrosion resistance is another critical consideration, especially for products exposed to harsh environments. Metals like aluminum and copper are naturally more resistant to corrosion compared to steel, which can rust without protective coatings. This property is essential in industries such as marine, chemical processing, and outdoor construction, where exposure to moisture and chemicals is frequent. Selecting a metal with inherent corrosion resistance can reduce maintenance costs and enhance the longevity of the product. For instance, stainless steel, an alloy containing chromium, offers excellent corrosion resistance while maintaining the strength of traditional steel.

Thermal Conductivity

Thermal conductivity plays a vital role in applications involving heat transfer. Metals like copper and aluminum excel in thermal conductivity, making them ideal for heat exchangers, radiators, and electronic cooling systems. In these applications, efficient heat dissipation is crucial to maintaining system performance and preventing overheating. Conversely, poor thermal conductors like some steels may not be suitable for such environments. It’s essential to match the metal’s thermal properties with the operational requirements of the product to ensure optimal functionality and safety.

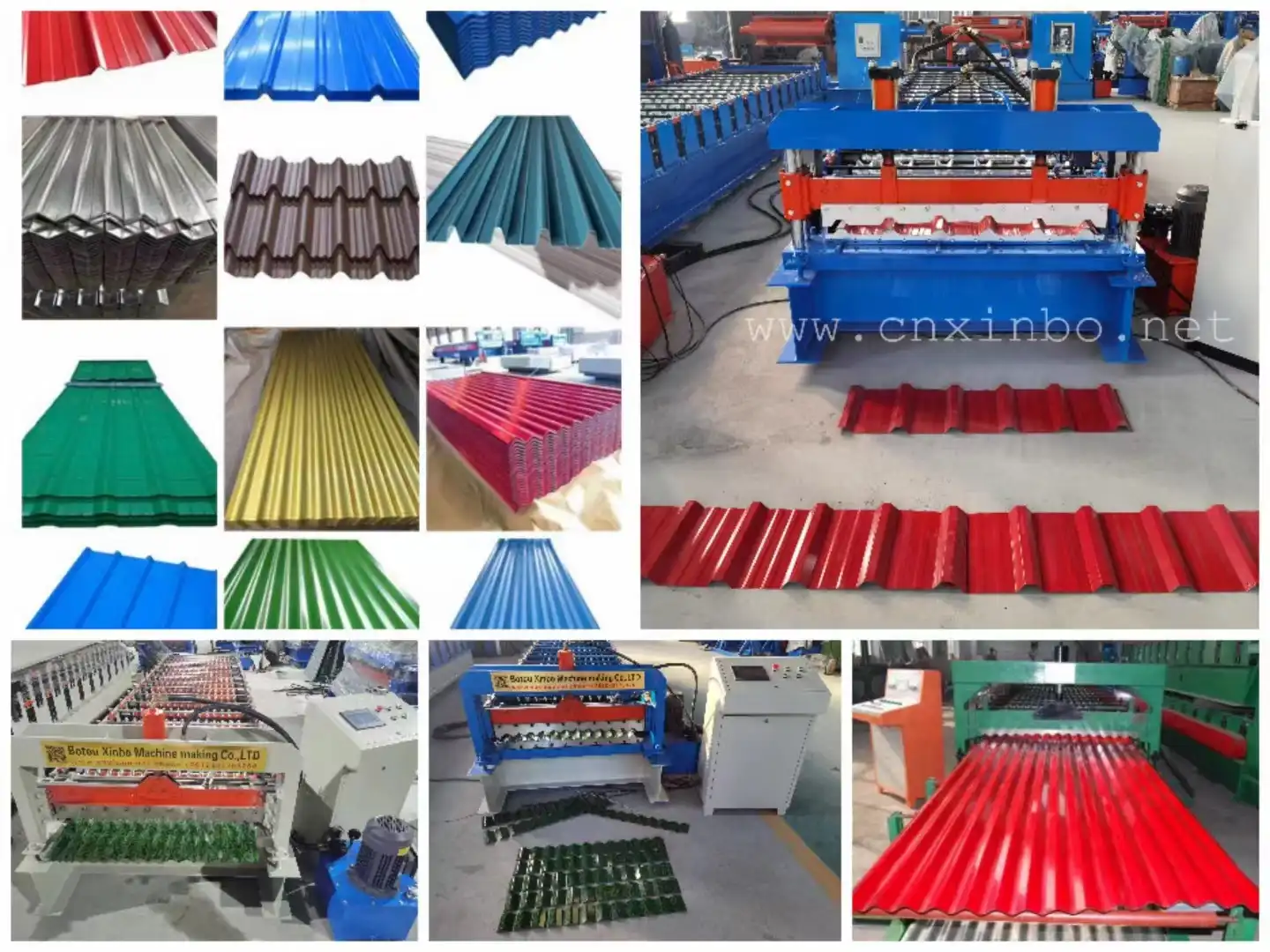

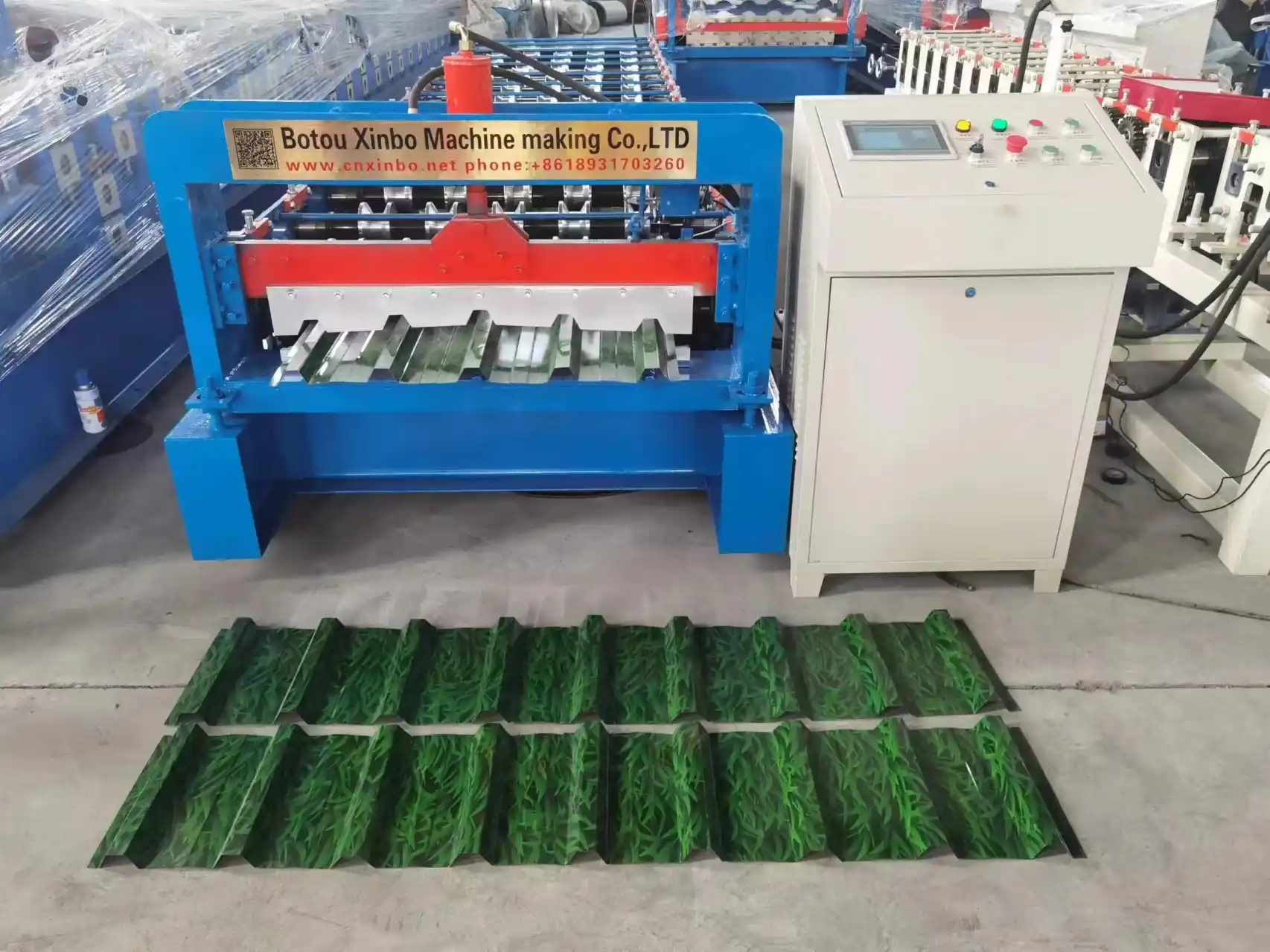

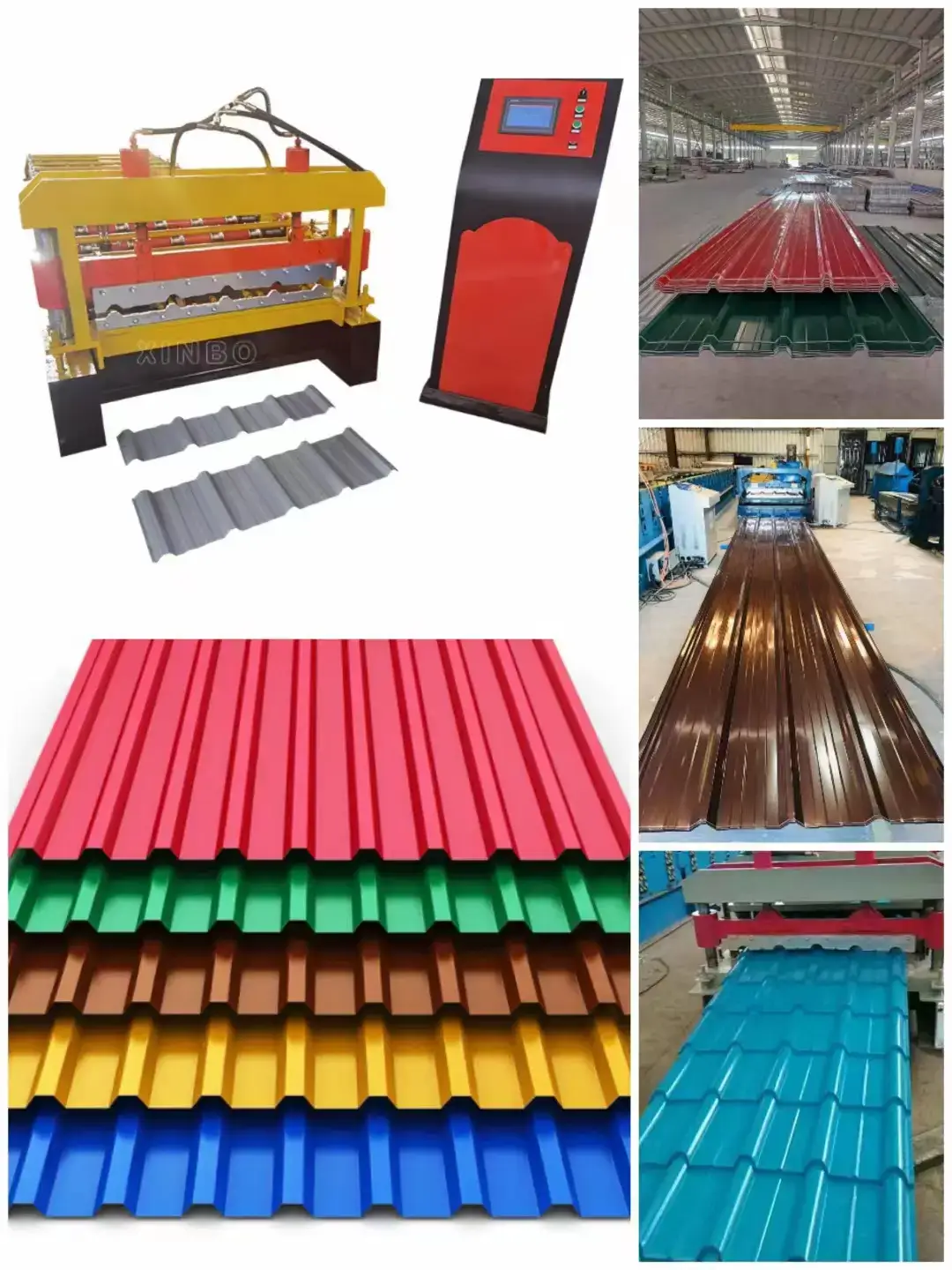

XINBO machine is a manufacturer which established in China since 2014. Quality assurance is provided by a team of our machine professional desiginer and producters and workers. New and innovative technology,such as roll forming machine, for the Europe, UK and Canada, as customer’s request and class. And we also have standard class for normal consumption.

Role of Sheet Metal Forming Machines

Types of Sheet Metal Forming Machines

Press Brakes

Press brakes are pivotal in the bending process of sheet metal forming. These machines utilize a set of dies to bend the metal sheets into desired angles and shapes. Available in mechanical, hydraulic, and CNC variants, press brakes offer precision and versatility, accommodating various material thicknesses and sizes. Their ability to produce complex bends with high accuracy makes them indispensable in fabricating parts like brackets, enclosures, and panels for numerous industries.

Roll Forming Machines

Roll forming machines are ideal for continuous bending operations, producing long metal sections with consistent profiles. These machines pass metal sheets through a series of rollers, gradually shaping the material. Roll forming is particularly efficient for high-volume production of parts like building materials, automotive frames, and metal furniture. The process is known for its minimal material waste and ability to maintain tight tolerances, enhancing both economic and manufacturing efficiency.

Stamping Presses

Stamping presses are used for operations such as punching, blanking, embossing, and coining, forming metal sheets into predetermined shapes. This method is highly efficient for mass production of components with consistent quality. Stamping presses can range from simple manual machines to highly automated systems, depending on the production scale requirements. Industries such as automotive, electronics, and household appliances heavily rely on stamping presses for their precision and speed in turning out large quantities of parts.

Compatibility with Different Metals

Sheet metal forming machines must be compatible with a wide range of metals to cater to diverse industrial needs. Each type of machine has its specialties, and understanding the compatibility can optimize the manufacturing process. For instance, press brakes are excellent for both steel and aluminum due to their flexibility, while roll forming machines perform best with metals that require continuous shaping, like steel and aluminum. Stamping presses, given their versatility, can handle various metals, including steel, aluminum, and copper, allowing for wide-ranging applications.

XINBO special designing as customer need, also allows the machines loaded in to a standard 40ft HQ container. The savings on logistic is essential for international clients. Our factory has ourself professional Engineers and designers, who can design the detail drawings as customers’need in short time. And keep the exactly same. We has ourself workshop and CNC machining machines and workers, this will save many cost and keep the process in same time with each steps. Designing and CNC. Each machine will be inspected in 3 times before shipping to customers.

Advances in Technology and Material Science

Innovations in Sheet Metal Forming Machines

Technological advancements have significantly enhanced sheet metal forming machines’ efficiency and precision. Modern CNC (Computer Numerical Control) systems have automated many aspects of the forming process, enabling highly accurate and repeatable operations. Innovations like servo-electric press brakes offer energy efficiency and precise control, while advancements in roll forming technology allow for the production of increasingly complex profiles. These innovations not only boost productivity but also reduce material waste and operational costs, leading to more sustainable manufacturing processes.

New Alloys and Their Impact on Formability

Material science continues to produce new alloys tailored to specific industrial needs. High-strength, low-alloy (HSLA) steels provide improved strength-to-weight ratios, which are critical in automotive applications aiming for better fuel efficiency. Advanced aluminum alloys offer enhanced corrosion resistance and mechanical properties suitable for aerospace components. These new alloys expand the range of possibilities in sheet metal forming, allowing for the development of lighter, stronger, and more durable products. Adapting to these materials can lead to significant improvements in product performance and manufacturing efficiency.

Practical Tips for Metal Selection

Consulting with Experts

Engaging with material scientists and industry experts can provide valuable insights into selecting the optimum metal for a given application. These professionals can evaluate specific requirements such as strength, flexibility, corrosion resistance, and cost, ensuring an informed decision. Expert consultation can help identify the most suitable metals and alloys, anticipate potential challenges, and recommend best practices for handling and forming the chosen material, ultimately leading to a more successful manufacturing outcome.

Running Prototypes Before Full Production

Before committing to full-scale production, running prototypes can validate the chosen metal’s suitability. Prototyping allows for the testing of material properties, assessing manufacturing processes, and identifying any unforeseen issues. This step is crucial in understanding how the metal performs under real-world conditions and making necessary adjustments. By catching potential problems early, manufacturers can save time and resources, ensuring the final product meets quality and performance standards.

Real-World Applications: Industries Utilizing Various Metals

Automotive Industry

The automotive industry extensively uses metals such as steel, aluminum, and increasingly, new alloys to meet the stringent demands of performance, safety, and efficiency. Steel remains a staple for chassis and structural components due to its high strength and durability. However, the shift towards lightweight vehicles for better fuel economy has increased the use of aluminum in body panels, engines, and wheels. Advanced high-strength steels (AHSS) are also gaining traction, offering superior strength with reduced weight, enhancing crashworthiness without compromising on efficiency.

Aerospace Sector

In the aerospace sector, the emphasis is on lightweight, high-strength materials to improve fuel efficiency and performance. Aluminum and its alloys are widely used for fuselage, wings, and other aircraft components due to their excellent strength-to-weight ratio and corrosion resistance. Titanium and advanced composites are also prominent, particularly in high-stress areas requiring exceptional durability and performance. The industry’s stringent standards necessitate meticulous material selection to ensure safety, reliability, and efficiency in aircraft manufacturing.

Consumer Electronics

Consumer electronics rely on metals like aluminum and copper for their conductivity, weight, and aesthetic qualities. Aluminum is often used in the construction of smartphone bodies, laptops, and other portable devices due to its lightweight and sleek appearance. Copper’s superior electrical conductivity makes it essential for internal wiring and components in electronic devices. The focus in this industry is on materials that provide optimal performance while allowing for innovative and stylish designs, catering to consumer demand for both functionality and aesthetics.

Closing Thoughts

Selecting the appropriate metal for sheet metal forming is a multifaceted decision that impacts every aspect of the manufacturing process, from efficiency and cost to the durability and performance of the end product. Understanding the properties and applications of common metals like steel, aluminum, and copper, as well as considering factors such as strength requirements, corrosion resistance, and thermal conductivity, can guide manufacturers in making informed choices. Advances in technology and material science continue to expand the possibilities, offering new avenues for innovation and efficiency in sheet metal forming. By consulting with experts and employing prototyping, manufacturers can ensure their metal selection aligns with their specific needs, leading to successful and sustainable production outcomes.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia