Mastering Double Layer Machine Operations for Optimal Output

Understanding the Basics of Double Layer Machines

Historical Evolution of Double Layer Machines

Double layer machines have transformed the manufacturing landscape since their inception. Initially, these machines emerged to enhance the efficiency of roll forming operations, catering to the demand for complex profiles while minimizing material waste. Over time, advancements in engineering and technology have led to the evolution of double layer machines, incorporating innovative features that allow for increased versatility in production capabilities. The historical progression reflects an ongoing pursuit of efficiency and output optimization.

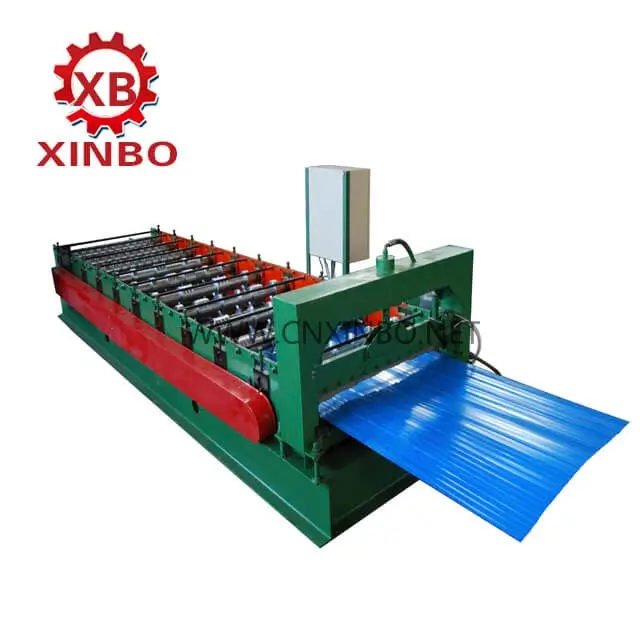

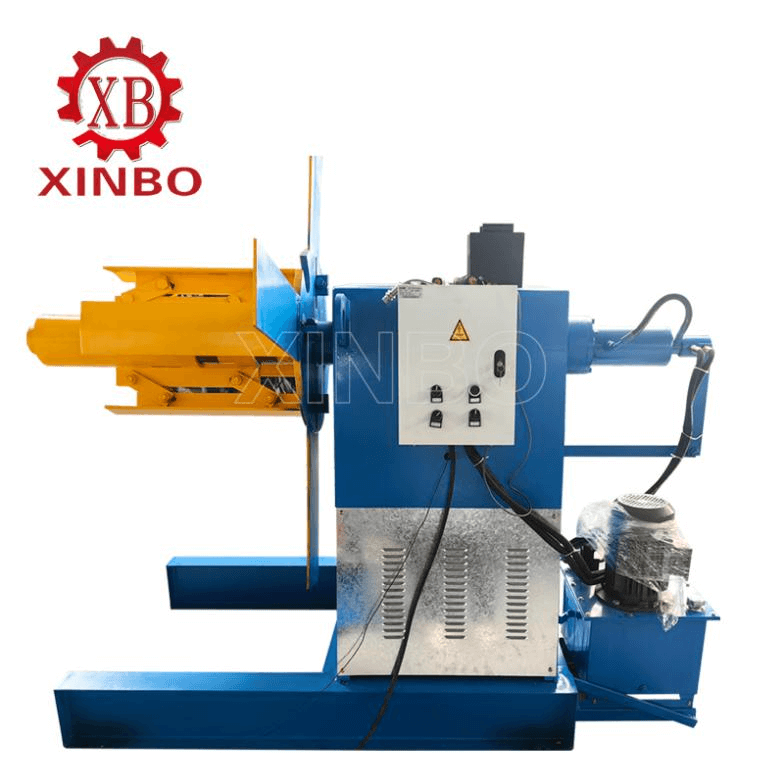

Key Features and Components

Double-layer machines have the capability of creating two profiles at the same time to make the manufacturing process more efficient and streamlined. The roll-forming frame hydraulic systems and control panels are vital parts in ensuring smooth operations. Additionally, double-layer machines come equipped with feeding mechanisms that help in handling materials. All these components work together to enhance the machine’s performance in producing top-notch products.

Differentiating Between Single and Double–Layer Roll Forming Machines

When it comes to rolling forming machines, double layers of operation capabilities differ significantly from each other. Single-layer machines are limited to producing one profile at a time whereas double-layer machines offer the advantage of producing two profiles. This added versatility not only helps in saving time but also cuts down on material expenses. Manufacturers need to evaluate their production requirements when selecting a machine since the flexibility of layer machines offers a notable edge for various applications.

Operational Techniques for Maximizing Efficiency

Setting Up the Double Layer Roll Forming Machine

Setting up a double layer roll forming machine requires careful attention to detail. Calibration and initial setup steps are essential to ensure optimal performance, including adjustments to roll spacing and tension. A robust setup guarantees that the profiles produced meet the desired specifications. Implementing safety measures and protocols is equally important, including proper operator training and adherence to safety regulations, reducing the risk of accidents and ensuring a safe working environment.

Maintenance Best Practices

Regular inspections and maintenance are crucial for the long-term functioning of dual-layer machines to ensure they operate smoothly without disruptions over time. Conducting checks helps in the detection of any possible problems before they become serious issues and impact the efficiency of the machines negatively. Some typical maintenance activities involve applying lubrication to components monitoring fluid levels and examining electrical parts for any signs of wear or damage. Knowing about maintenance issues. Their solutions can prevent costly downtimes and improve the overall reliability of the machines in the long run.

Enhancing Productivity Through Advanced Strategies

Optimizing Material Flow in Double-Layer Machines

Efficiently managing the movement of materials in dual-layer machines is essential for boosting productivity to its potential. Smooth processes and effective material handling systems guarantee that raw materials are smoothly fed into the machine without any interruptions. Incorporating a feeding system reduces downtime from interventions and supports a consistent production rhythm. By giving attention to material logistics management manufacturers can greatly improve their production capabilities.

Integration with Automation Technologies

Integrating automation technologies into the operation of double layer machines offers substantial advantages. Automation enhances precision and consistency, reducing human error and increasing overall output quality. Adopting AI and IoT solutions allows for real-time monitoring of machine performance, enabling operators to make data-driven decisions that can improve operational efficiency. The benefits of automation integration extend beyond production, impacting inventory management and supply chain efficiencies as well.

Troubleshooting Common Issues in Double Layer Machine Operations

Identifying Frequent Problems

It’s crucial to spot issues in operating double-layer machines to keep productivity on track. Some usual problems involve rolls not lining up correctly irregular material feeding and glitches in the system. By checking and evaluating the equipment, operators can catch these issues making it easier to address them promptly. Knowing the hurdles that may arise helps teams come up with solutions for fixing any problems that come their way.

Comprehensive Problem-Solving Techniques

Utilizing methods to solve problems is crucial when dealing with challenges that occur in the operation of dual-layer machines. Utilizing tools like programs and performance monitoring systems can help pinpoint the underlying reasons behind issues. Immediate solutions may include tweaking machine configurations or swapping out worn-out parts while more lasting resolutions could involve upgrading machine technology or providing training for operators. Taking a stance towards issue resolution can improve the reliability and performance of machines.

Case Studies: Real-World Applications of XINBO Double Layer Roll Forming Machines

Overview of XINBO’s Product Range

At XINBO we provide a selection of dual layer roll forming machines to cater to manufacturing requirements. That includes specifications and technical information showcasing the machines’ abilities like roll configurations and suitability for different materials with customizable options. Noteworthy attributes such as user interfaces and advanced control systems make XINBO machines a strong contender in the market. The clever design encourages operation while supporting a variety of profiles.

Success Stories from Industrial Clients

Numerous businesses, in the sector have seamlessly incorporated XINBO’s dual layer machinery into their processes with results to show for it. These real-life examples highlight the impact these machines have had on streamlining production schedules and minimizing waste while elevating the quality of goods in different industries. These success stories emphasize the applications of XINBO products. Underline the transformative effects that customized solutions can have on operational efficiency.

Future Trends in Double-Layer Machine Technology

Emerging Technologies Shaping the Future

The evolution of layer machine technology is shaped by technologies that are constantly emerging in the field of materials science and automation as well as advancements in digital modeling methods. That enable machines to perform with improved features and capabilities Smart manufacturing procedures integrating AI machine learning and 3D printing technologies are expected to bring about significant changes in production processes. Keeping up with these developments is essential for manufacturers who want to stay ahead in the competitive market.

Predictions and Innovations in Roll Forming Machines

Continuing innovations in roll forming machines suggest a dynamic future driven by technological advancements. Predictions include enhanced energy efficiency, greater precision in profile production, and increased integration with Industry 4.0 principles. As manufacturers embrace these innovations, the operational landscape for double layer machines will evolve, presenting opportunities for improved productivity and sustainability.

Conclusion: Mastery in Double Layer Machine Operations with XINBO Solutions

The mastery of double layer machine operations, particularly through XINBO solutions, represents a significant opportunity for manufacturers aiming for optimal output. By understanding the fundamentals, employing efficient operational techniques, and leveraging advanced technologies, organizations can maximize their double layer machines’ performance and productivity. Ultimately, continuous improvement and adaptation to emerging trends will empower manufacturers to excel in their industries.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia