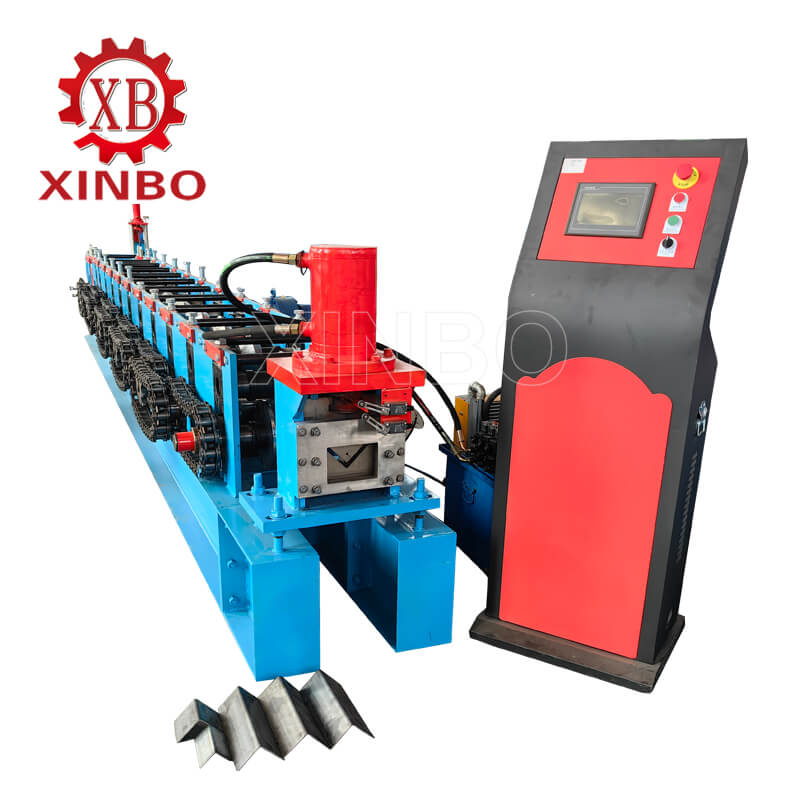

How to Compare Wall Angle Machines: A Guide for First-Time Buyers

In the construction and interior design field, where precision and efficiency are key, wall angle roll-forming machines are a necessary investment. These machines manufacture high-quality wall angles used to give support and add beauty to the ceilings and walls.

With so many options available, selecting the right machine for first-time buyers can be quite overwhelming. This guide simplifies the decision-making process by outlining the key factors to consider and introducing Xinbo‘s Wall Angle Roll Forming Machines, a trusted leader in the industry.

What are Wall Angle Machines?

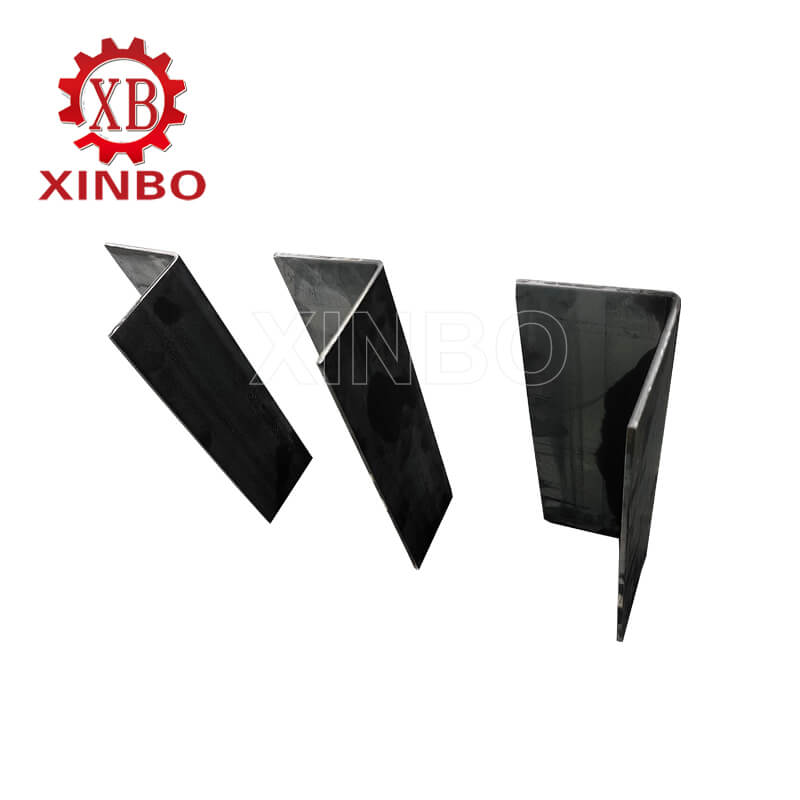

Wall angle roll-forming machines are specialist equipment that will change flat steel sheets, such as galvanized steel, into precise wall angles. These wall angles are then used in constructing ceiling frameworks and wall linings, which are part of residential, commercial, and industrial projects.

Benefits of Wall Angle Machines

Precision: Automatically produced wall angles have consistent dimensions, thus ensuring quality.

Efficiency:A modern machine can reduce a lot of production time for faster completion of projects.

Customization: Advanced features allow the making of customized profiles to meet particular project needs.

Reliability: Sturdy machines are capable of undertaking heavy work and are constructed to last long.

Investment in a good-quality wall angle roll-forming machine means higher efficiency, reduced labor cost, and improvement in project results.

Wall Angle Machines: Buying Factors

Buyers have to make a very informed decision considering different aspects of design, functionality, and compatibility of the machine.

1. Material Compatibility

The materials a machine can process determine its versatility and suitability for different applications.

Xinbo Advantage: Xinbo’s machines are optimized for GI coils with customizable input and formed width. They support materials with a processing thickness of up to 4.0mm, ensuring they can handle demanding construction tasks.

2. Production Speed

For large-scale operations, production speed is a critical factor. A machine with high-speed capabilities ensures timely project completion.

Xinbo Advantage: The standard speed of 0–15m/min provides an excellent balance of precision and efficiency. The production speed is also customizable according to the requirement.

3. Durability and Frame Design

The frame and build quality of the machine directly affect its longevity and performance under heavy use.

XINBO Advantage: The 400mm H Beam Welded Frame gives the machine increased strength and stability. Rollers are made of 45# steel, heat treated and hard-chromed to resist wear.

- Shearing and Measuring Precision

It requires correct cutting and measurement of lengths to get wall angles correctly to specification.

Xinbo Advantage: Hydraulic profile cutting offers clean, accurate cuts. An encoder-based length measuring system ensures consistent accuracy with each and every output.

- Ease of Operation

Friendly machinery reduces errors and saves time by reducing the need for operator training.

Xinbo Advantage: Xinbo machines combine PLC-controlled systems with button operation with a touch screen interface; easy to learn, easy to operate.

- Power and Voltage Requirements

Machines must align with your facility’s power setup. Buyers should check the power output and voltage compatibility.

Xinbo Advantage: These machines have a power setup of 5.5+4KW and customizable voltage options, ensuring compatibility with various electrical systems worldwide.

- Customization Options

For businesses with unique project needs, customization is a key feature to consider.

Xinbo Advantage: Xinbo provides ODM & OEM services, which enable clients to have their machines tailored to specific profiles, dimensions, and production speeds.

- Quality Assurance

A good manufacturer will have stringent quality checks in place to ensure that the machine’s performance is consistent and downtime is minimized.

Xinbo Advantage: Xinbo performs a strict three-step quality inspection on all machines-after assembly, during testing, and pre-shipment-to ensure reliability.

Why Choose Xinbo’s Wall Angle Roll Forming Machines?

Established in 2014, Xinbo has built a reputation as a trusted manufacturer of roll-forming machines. Here’s what sets Xinbo apart:

1. Tailored Solutions

Xinbo’s experienced engineers and designers work closely with clients to create detailed blueprints and deliver machines that meet specific requirements.

2. Competitive Pricing

By managing the entire production process in-house—from CNC machining to assembly—Xinbo keeps costs low while maintaining high quality.

3. Quick Turnaround

Xinbo’s integrated design and manufacturing processes allow for short lead times, helping businesses stay on schedule.

4. Uncompromising Quality

Xinbo conducts multiple quality checks, providing customers with documented testing results for every machine.

5. Compliance with Global Standards

All Xinbo machines adhere to international IEC standards, ensuring reliability and safety for users worldwide.

Material Compatibility: GI coils with customizable input and formed width.

Processing Thickness: Up to 0mm.

Frame Design: Durable 400mm H Beam Welded Frame.

Production Speed: Standard speed of 0–15m/min(customizable).

Control System: Intuitive PLC-controlled interfacewith touch screen.

Cutting Mechanism: Precise hydraulic profile cutting.

Customizability: Options for speed, width, and power output.

This makes the machines from Xinbo highly suitable for projects of commercial, residential, and industrial sectors.

Applications of Wall Angle Machines

Wall angle roll-forming machines are versatile tools used in several fields of endeavor, as illustrated:

1. Commercial Construction

- Salient in office buildings, shopping malls, and conference centers to make strong ceiling frameworks.

2. Residential Projects

- Strengthens modern home designs by shaping wall angles with high precision to fit wall lining and decoration needs.

3. Industrial Use

- Brings stability to warehouses and factories, holding firm heavy construction demands.

Tips for First-Time Buyers

If you’re new to the world of wall angle roll-forming machines, these tips will help you make an informed purchase:

1.Understand Your Project Requirements

Identify your material type, production volume, and customization needs before shopping.

2.Compare Features

Focus on material compatibility, production speed, cutting precision, and ease of operation.

3.Ask About Customization

Ensure the machine can be tailored to your unique specifications.

4.Evaluate Quality Assurance

Choose manufacturers like Xinbo, which prioritize comprehensive quality checks.

5.Consider Long-Term Value

Look for machines featuring hard-wearing parts, low maintenance, and good resale value.

Conclusion

A wall angle roll-forming machine can bring a sea change for the first-time buyers of any business. Pay extra attention to the compatibility of materials, robustness, the precision of cutting, and operation efficiency, and you will definitely get value for money.

With advanced features, strong customization options, and a focus on quality, Xinbo can be the partner in the industry for wall angle machines that are both reliable and efficient. Their machines will raise your production bar by ensuring precision and consistency down to every detail.

Is it time to take construction projects to the next level? Have a look at wall angle roll-forming machines from Xinbo and experience it for yourself.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia