How Scaffolding Panel Machines Enhance Structural Integrity?

What Role Do Scaffolding Panel Machines Play in Construction?

Scaffold panel machines play a role in the construction sector by serving as the foundation for crafting elements, such as scaffold panels efficiently and accurately to support structures securely and effectively.

The Importance of Scaffolding Panels in Structural Support

Scaffolding panels play a role in construction projects by offering support and entry points to different sections of a building being built or renovated. They are essential for ensuring the safety of workers and enabling the movement of materials around the site. The quality of these panels significantly affects the safety standards of the construction site underscoring the importance of using machinery for their production.

How Do Scaffolding Panel Machines Improve Efficiency?

Scaffolding panel machines improve productivity by automating production tasks and cutting down work while also reducing mistakes in the process. The aim is to manage production volumes smoothly while maintaining high quality. This speeds up project schedules and cuts down costs related to delays or fixing problems with faulty scaffolding parts.

Why Is Precision Important in Scaffolding Panel Production?

It is essential to maintain precision when manufacturing scaffolding panels to guarantee a fit within a structure and offer support while prioritizing safety measures.

The Impact of Precision on Structural Safety

When scaffolding panels are produced with high precision, they contribute significantly to structural safety. Precise manufacturing ensures that panels can withstand expected loads and environmental stresses without deformation or failure, thereby protecting workers and maintaining project integrity.

How Does Technology Enhance Precision?

Cutting-edge technology is crucial for improving accuracy in the manufacturing of scaffolding panels as sophisticated machines with automated control systems enable adherence to specifications on a basis, thereby minimizing human mistakes and guaranteeing uniformity across all panels manufactured.

How Do Scaffolding Panel Machines Contribute to Cost-effectiveness?

Scaffold panel machinery provides solutions by maximizing resources and minimizing waste in manufacturing processes. The automation integrated into these machines reduces labor expenses. Boosts productivity levels making them a practical option for construction ventures.

The Economic Benefits of Using Advanced Machinery

Investment in state-of-the-art scaffold panel equipment can bring about advantages such as minimizing material wastage through accurate cutting and shaping functions; decreasing maintenance expenses due to sturdy machine parts and enhancing productivity by expediting production processes.

What Are the Operational Savings?

The cost savings achieved by utilizing scaffolding panel machines are significant. These machines help decrease labor costs by reducing the need for labor while still ensuring productivity levels. Moreover, their energy-efficient operation leads to reduced expenses in the run, which makes them a desirable choice, for construction firms seeking to enhance their bottom-line profitability.

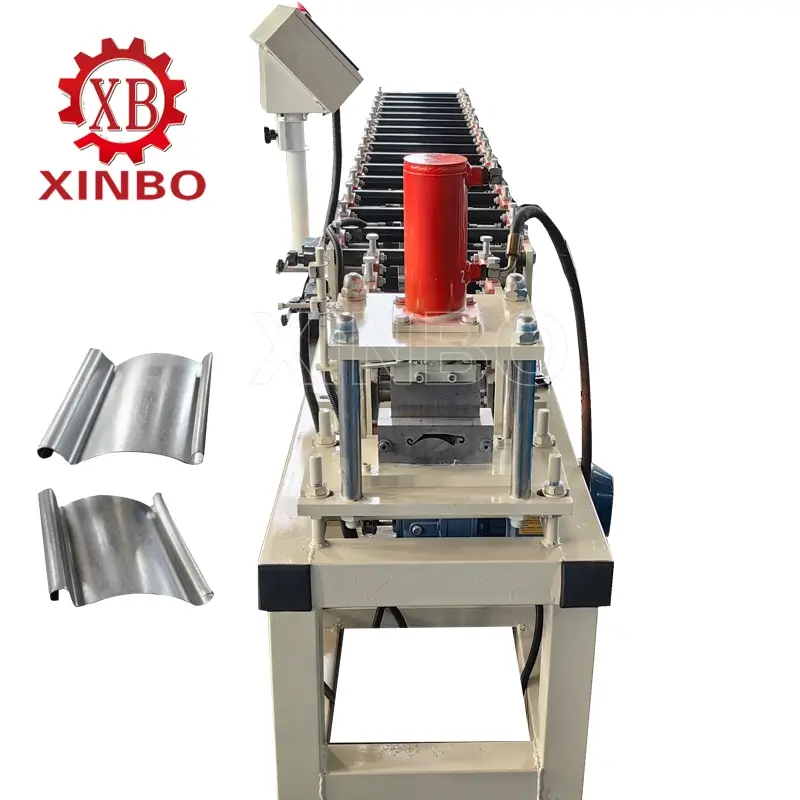

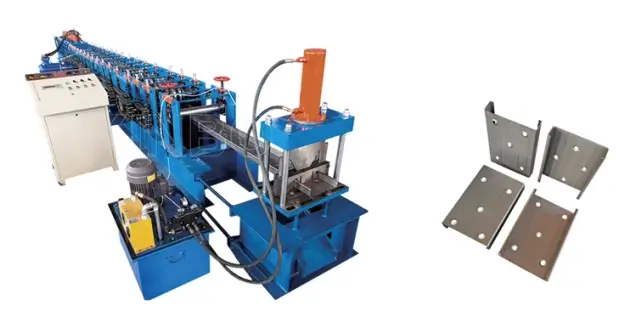

Looking for machinery options for construction projects? XINBO MACHINE MAKING CO., LTD is a choice known for its quality offerings like IBR roll forming machines and sandwich panel roll forming machines designed for needs and applications in the industry. Find a selection of products at XINBO MACHINE MAKING CO., LTD to elevate the effectiveness and accuracy of your construction work today.

Ultimately supporting panel devices are instruments that boost the solidity of structures by enhancing efficiency, exactness, and cost effectiveness. By utilizing cutting-edge technology and machinery from companies such as XINBO MACHINE MAKING CO., LTD you can guarantee prosperous construction endeavors.

How Can You Choose the Right Scaffolding Panel Machine?

Choosing the scaffolding panel equipment is vital to guaranteeing the effectiveness and safety of your building endeavors as it can greatly influence both the caliber of the scaffolding panels manufactured and the productivity of your activities.

Key Considerations for Selecting Machinery

When you’re selecting a scaffolding panel machine for your projects there are a few things to keep in mind. Firstly, consider the needs of your projects such as the type and quantity of panels required. Check if the machine can handle these requirements effectively. Look into the technology used in the equipment; modern features like control systems can improve accuracy. Minimize mistakes. Also factor in the durability and dependability of the machine as these aspects impact maintenance expenses and operational downtime, in the run.

When choosing a machine, it’s crucial to take into account the manufacturer’s reputation go for devices produced by reputable companies recognized for their top-notch products and excellent customer service this way you can rest assured that you’ll have the necessary support and spare parts available whenever required.

Why Is XINBO MACHINE MAKING CO. LTD a Leading Choice?

XINBO MACHINE MAKING CO., LTD has built a reputation as a provider of scaffold panel machinery thanks to its dedication to quality and groundbreaking ideas in the field of manufacturing equipment production, like decking floor and supermarket shelf panel machines to meet different industry requirements effectively by incorporating cutting edge technology for increased precision and productivity.

Furthermore, XINBO values customer satisfaction with their support services and the availability of spare parts. By opting for XINBO products, you are investing in dependable equipment that improves project results and reduces operational interruptions. Learn more about what they offer by visiting XINBO MACHINE MAKING CO., LTD.

How Does Investing in Quality Machinery Benefit Your Projects?

Acquiring top-notch equipment isn’t for short-term benefits. Also lays the groundwork for lasting prosperity in construction endeavors.

Long-term Advantages of High-quality Equipment

Notch scaffolding panel equipment provides a range of lasting benefits in the run by maintaining consistent production quality to minimize rework and material waste effectively resulting in substantial cost savings over time through reduced resources used for error correction and faulty panel replacements.

Sturdy equipment not only leads to reduced maintenance expenses and frequent disruptions but also ensures that projects can remain on track as planned. Moreover, modern machinery typically incorporates energy-saving features that help cut down expenses by minimizing energy usage.

Enhancing Project Outcomes with Reliable Technology

Effective technology is essential, in improving project results by guaranteeing that all elements meet criteria without any concessions. When utilizing equipment such as those provided by XINBO MACHINE MAKING CO., LTD. you can have faith that each scaffold panel made will add value to the stability.

This dependability leads to safety at construction sites as made panels offer greater support and stability thereby increasing productivity by allowing workers to concentrate on advancing tasks without having to troubleshoot equipment problems or handle faulty materials.

Integrating notch scaffolding panel machinery into your workflow doesn’t just improve the strength of structures. Also maximizes resource efficiency to achieve project success, within budget limits smoothly and effectively Partnering with trusted suppliers such as XINBO MACHINE MAKING CO., LTD ensures access to state-of-the-art solutions customized to fulfill your unique construction requirements.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia