How Roll Forming Machines Shape Our Lives: From Automobiles to Home Appliances – Everywhere

The roll forming machine is an indispensable piece of equipment in industrial production, and it has a profound impact on our daily lives, which is mainly caused by its unique working principle and wide range of applications. It is everywhere, from automobiles to home appliances and from construction to aerospace, effecting every aspect of modern life.

Basic Principles and Features of Roll Forming Machines

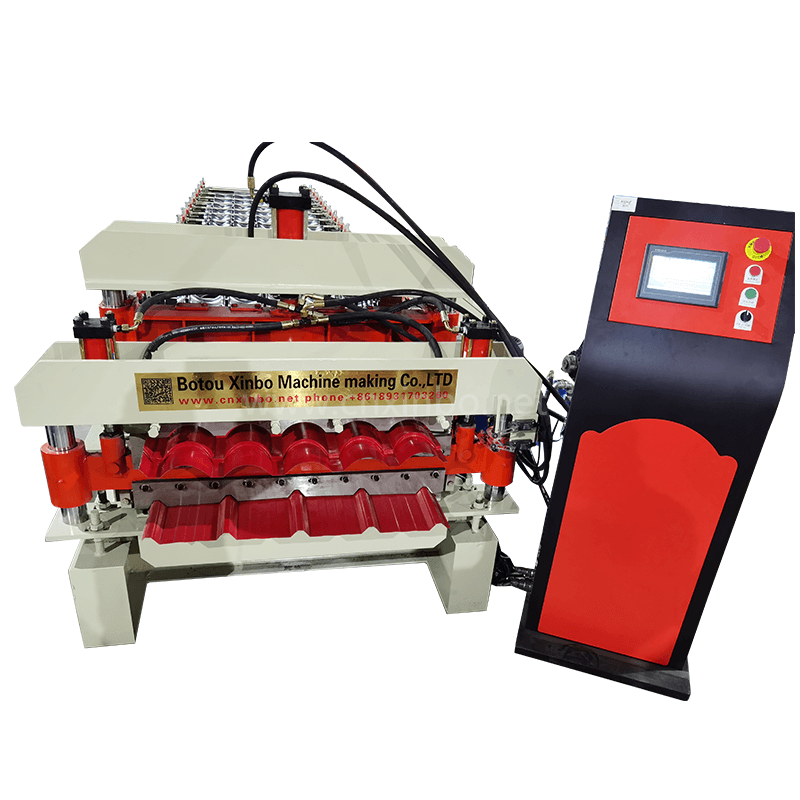

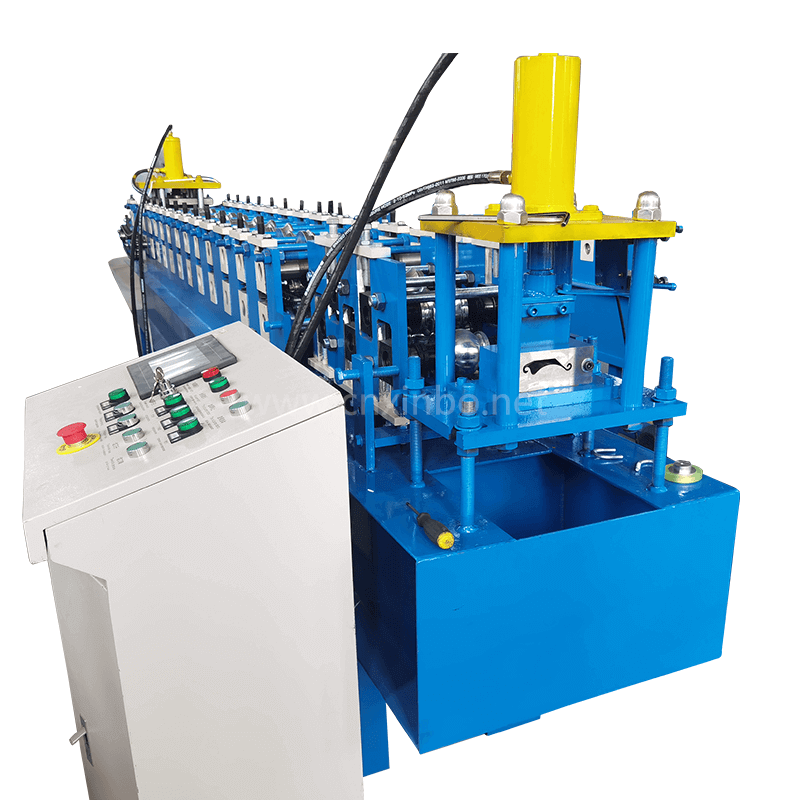

Roll Forming Machines are based on the principle of plastic deformation, in which continuous pressure is applied to the material by rollers, causing the material to flow plastically so as to achieve the desired shape and size. This type of molding is characterized by high precision, high efficiency, and high adaptability, and is capable of handling a wide variety of materials, including metals and plastics, and of processing complex and diverse shapes and structures.

Application of Roll Forming Machine in Automobile Manufacturing

As the main transportation force in modern society, the role of roll forming machine in the manufacturing process of automobile cannot be ignored.

Body manufacturing: Roll forming machines play an important role in body manufacturing. Through precise roll forming process, high-strength and lightweight body frames and parts, such as cross beams, longitudinal beams, door frames and so on, can be manufactured. These components not only improve the safety and comfort of the vehicle, but also help to reduce fuel consumption and emissions.

Engine and transmission system: Roll forming machines are also widely used in the manufacture of engines and transmission systems. Critical components such as crankcases, cylinder blocks, gearboxes, etc. can be accurately manufactured through the roll forming process. These components need to withstand extreme conditions such as high temperatures, high pressures and high speeds, and the high precision and stability of roll forming machines ensures their quality and performance.

Roll Forming Machines in Home Appliances Manufacturing

Home appliances are closely linked to our lives, and roll forming machines play an important role in the manufacture of home appliances.

Shells and Structural Parts: The shells and structural parts of home appliances need to be strong and aesthetically pleasing. Roll forming machines can accurately produce shells and structural parts of various shapes, such as door panels for refrigerators, drums for washing machines, and outdoor units for air conditioners. These parts require not only accurate shapes, but also smooth and beautiful surfaces, and roll forming machines can meet these requirements.

Pipes and connectors: Many home appliances have complex systems of pipes and connectors inside, such as condensers, evaporators and refrigerants for air conditioners. Roll forming machines are able to produce pipes and connectors of various shapes and sizes, ensuring their tightness and stability. These pipes and connectors need to withstand certain pressures and temperatures, and the high precision and reliability of roll forming machines ensure their quality and performance.

Roll Forming Machines in Other Fields

Apart from the automotive and home appliance industry, roll machinery plays an important role in other industries.

Construction: Scroll machines are also used extensively in the construction industry especially for fabrication of steel structural components and pipeline systems Metal structural components, such as steel frames, in bridges, office buildings, stadiums, and etc. in construction Steel machinery is used to manufacture , steel columns, steel plates, etc. Additionally, roll forming machines can form pipes and connections for heating, ventilation and air conditioning systems, providing comfort and safety in the building

Aerospace: In the aerospace industry, roll forming machines are used to produce precise, high-strength components, such as airframes, engine components, fuel systems, etc. Applications for which this is important large for aircraft, spacecraft and rockets which must depend on surface flight conditions and stress design. The designed parts are able to meet these requirements, providing significant support to the aerospace industry.

Medical Devices: Roll mills also play an important role in the manufacture of medical devices, which require high precision and safety Roll mills are capable of producing surgical instruments, dental devices, medical bed frames and pharmaceuticals other necessary devices. Medical devices manufactured by roll machinery are accurate, stable and comply with hygiene standards, contributing significantly to health care.

Pipes and connections: Many home appliances have sophisticated arrangements of pipes and connections, such as condensers for air conditioning, evaporators, refrigerators and roll forming machines can make pipe connections in various shapes and sizes to ensure durability and stability These pipe connectors must withstand certain pressures and temperatures, the high accuracy and reliability of the roll forming machinery ensure quality and efficiency.

Conclusion

Because of its unique working principle and wide range of applications, Roll Forming Machine has profoundly affected our daily lives, including automobiles, home appliances, construction and aerospace. It can be said that it is everywhere, making our living environment more convenient, comfortable and safe. With the progress of science and technology and the development of manufacturing industry, there is no doubt that roll forming machine can continue to play its important role and bring more innovations and surprises to our life.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia