How Proper Setup of a Roll Forming Machine Enhances Metal Form Production

Understanding Roll Forming Machines

Basics of Roll Forming

Roll forming is a continuous bending operation in which a long strip of sheet metal, typically coiled steel, is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend until the desired cross-section profile is obtained. This process is highly efficient for producing metal components with uniform cross-sections and is widely used in various industries, including automotive, construction, and aerospace.

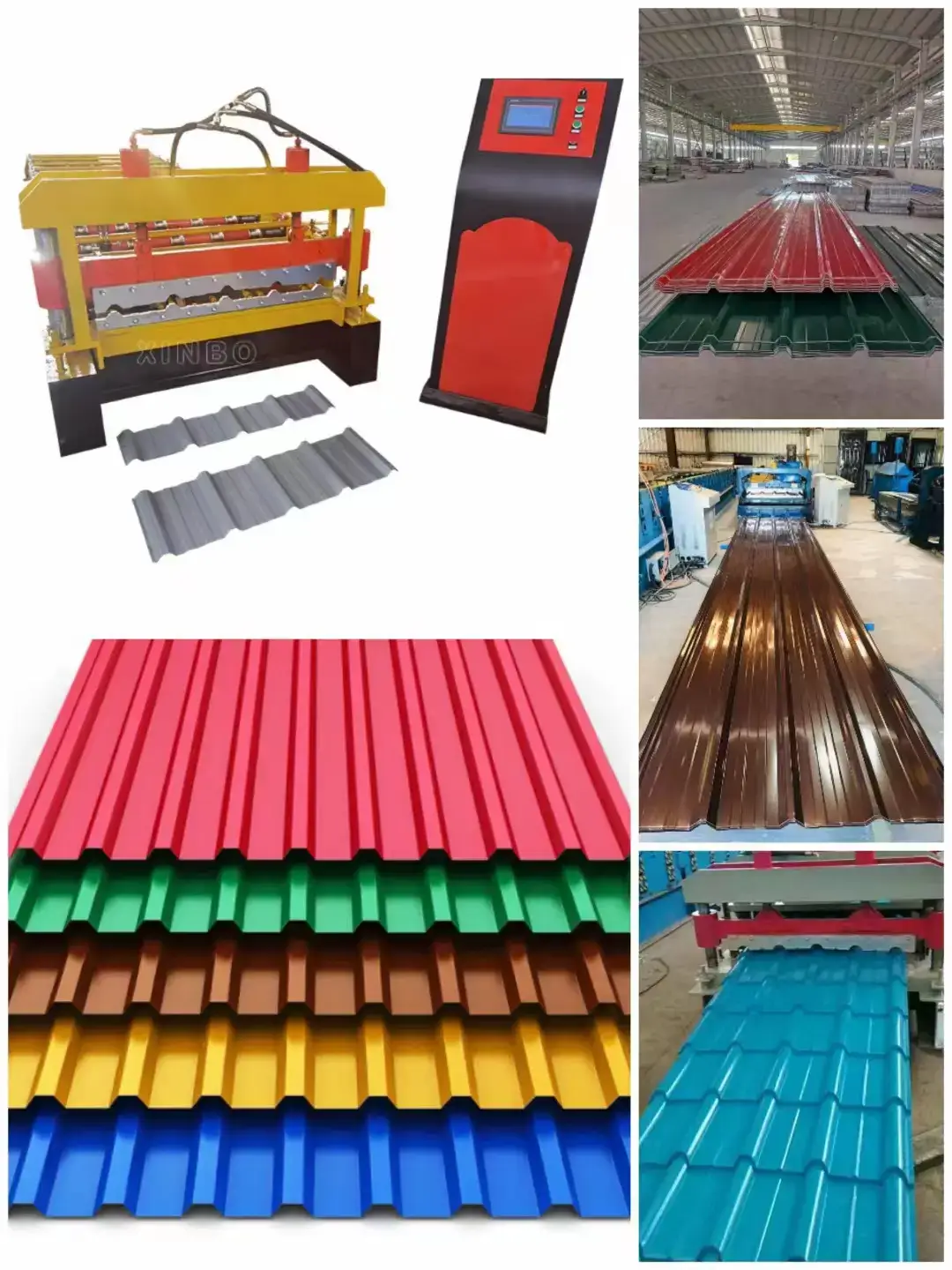

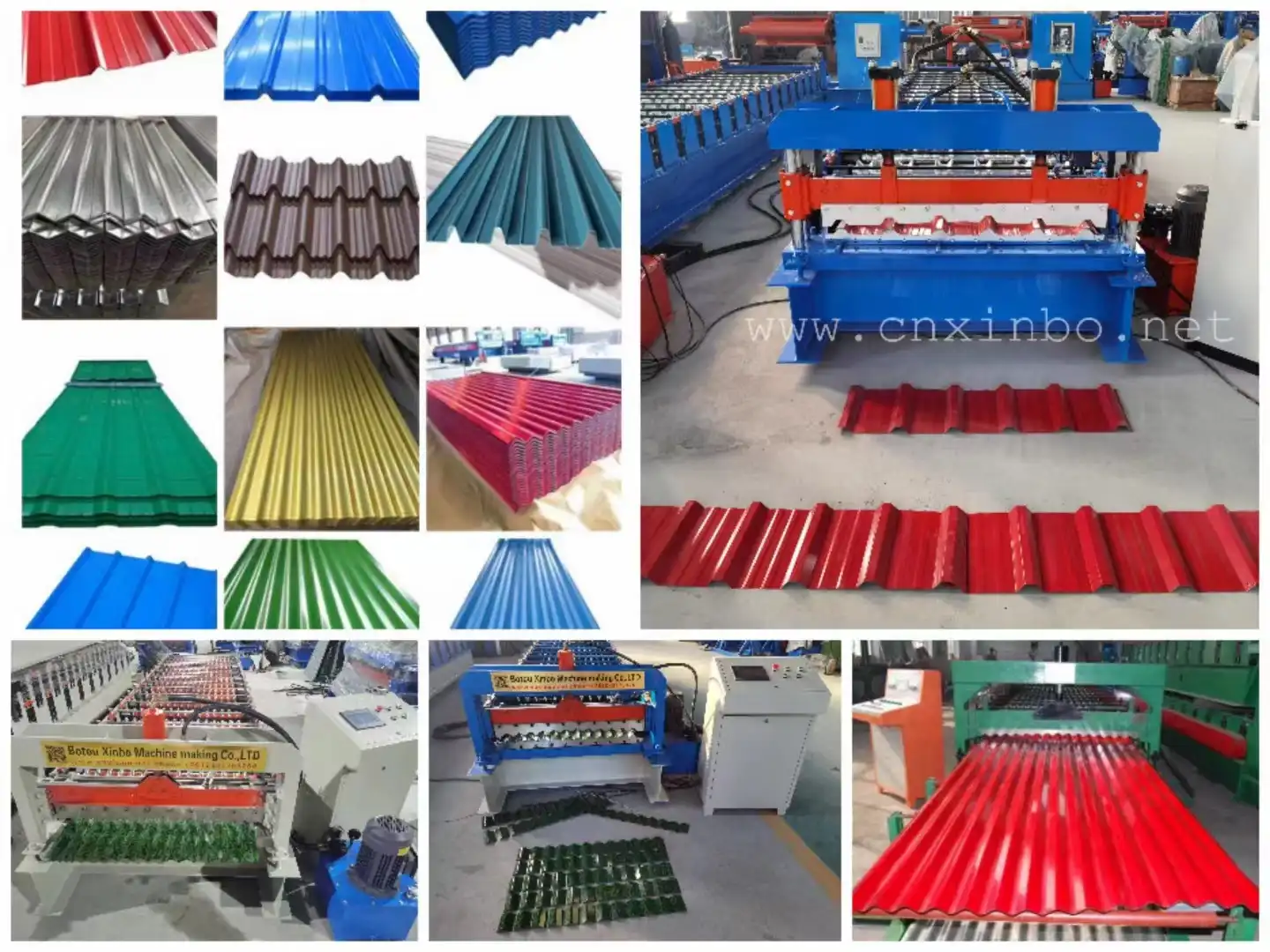

XINBO special designing as customer need, also allows the machines loaded in to a standard 40ft HQ container. The savings on logistic is essential for international clients. Our factory has ourself professional Engineers and designers, who can design the detail drawings as customers’need in short time. And keep the exactly same. We has ourself workshop and CNC machining machines and workers, this will save many cost and keep the process in same time with each steps. Designing and CNC. Each machine will be inspected in 3 times before shipping to customers.

Key Components of Roll Forming Machines

A roll forming machine comprises several essential components. These include the entry section, where the metal strip is loaded, and guide rolls to steer the material correctly. The stands, equipped with specific rolls, progressively bend the material to the desired shape. The drive system ensures consistent rolling speed, and the cut-off press or saw at the end of the machine trims the final product to the required length. Additionally, control systems monitor and adjust the process parameters to ensure precision and quality.

Applications of Roll Forming Machines in Metal Forming

Roll forming machines have a wide range of applications, primarily in industries that require high-volume production of metal profiles. In the automotive industry, they are used for making structural parts such as frames and supports. The construction industry benefits from roll-formed products like roofing panels, gutters, and steel studs. In the aerospace sector, roll forming helps achieve lightweight and high-strength components. The versatility and continuous nature of roll forming make it a preferred choice for manufacturing consistent, high-quality metal forms.

Preparing the Work Environment for Setting Up

Ensuring Safety and Compliance

Safety is paramount when setting up a roll forming machine. Ensure all safety protocols and compliance measures are in place. This includes wearing personal protective equipment (PPE) such as gloves, helmets, and safety glasses. The area around the machine should be free of obstructions and marked with safety signage. Regularly check that emergency stop buttons are functional and easily accessible. Compliance with local regulations and standards, such as OSHA guidelines, is essential to prevent accidents and ensure a safe working environment.

Necessary Tools and Equipment

Setting up a roll forming machine requires a specific set of tools and equipment. Basic tools like wrenches, screwdrivers, and alignment indicators are essential for assembly and adjustments. Precision measuring instruments such as micrometers, calipers, and dial gauges are necessary to ensure accurate settings. Additionally, having a stock of spare parts, including rollers and bearings, can be crucial for quick replacements during setup and maintenance. A well-equipped toolbox helps in minimizing downtime and ensuring the machine operates efficiently.

Material Selection and Preparation

The quality of the finished metal product heavily depends on the initial material selection and preparation. Choose materials that are compatible with the roll forming process, typically high-strength steels and aluminum alloys. Ensure the metal coils are clean, free of rust, and properly lubricated to facilitate smooth passage through the rolls. Inspect the coils for any defects or irregularities that may affect the forming process. Proper material preparation is key to achieving uniform and high-quality outputs.

Steps to Set Up a Roll Forming Machine

Machine Calibration and Alignment

Proper calibration and alignment are crucial steps in setting up a roll forming machine. Incorrect settings can lead to defective products and machine wear.

Aligning the Rolls

Begin by ensuring that each set of rolls is perfectly aligned. Misalignment can cause irregularities in the finished product and unnecessary wear on the machine components. Use precision instruments like alignment indicators and laser tools to verify that the rolls are correctly positioned. This step involves adjusting the lateral and vertical positions of the rolls to match the desired profile specifications. Consistent alignment checks should be performed throughout the setup process to maintain accuracy.

Adjusting Roll Pressure and Position

Proper roll pressure is essential to achieve the desired metal form without damaging the material. Adjust the pressure settings based on the thickness and type of metal being used. Too much pressure can cause cracks or deformation, while too little pressure may result in incomplete forming. Fine-tuning the roll position, both horizontally and vertically, ensures uniformity in the final product. Utilize dial gauges and pressure sensors to monitor and adjust these settings precisely.

Loading the Material into the Machine

Loading the material into the roll forming machine is a critical step that demands precision and care. The method of feeding metal into the machine can vary depending on the type of metal and its thickness. For thin materials, hand feeding can be adequate, but heavy and thicker metals usually require mechanical feeding systems. Adjust the guide rolls to ensure the material is properly aligned before entering the rollers. Double-check that the metal strip is free of kinks and uniformly straight to avoid any bending or jamming issues.

Feeding Techniques for Different Metal Types

Different metals demand specific feeding techniques to optimize the roll forming process. For example, aluminum, which is more flexible, may need a gradual feed-in to prevent bending. Harder metals like steel might require pre-heating or lubrication to facilitate smooth feeding and rolling. Ensure that the feeding speed is consistent and matches the machine’s rolling speed to prevent material distortion. Understanding the material properties and troubleshooting during the feeding process helps in achieving high-quality metal forms and prolonging the machine’s life.

Performing Test Runs

Once the material is loaded, executing test runs is essential for verifying that all settings are accurate and the machine operates efficiently. During test runs, observe the material flow through each stage of the rollers. This phase allows operators to detect any misalignments, irregular pressures, or defective areas that might appear in the final product. Make necessary adjustments in real-time, including fine-tuning of the roll positions and pressures, to ensure the machine produces the desired quality and specifications. Continuous test runs and adjustments contribute to achieving a smooth and efficient roll forming process.

Troubleshooting Common Issues During Setup

Addressing Misalignment Problems

Misalignment issues are common during the roll forming machine setup and can lead to defective products. To address these, constantly monitor the alignment of the rolls during the setup phase. Use alignment indicators and laser alignment tools to identify any deviations and adjust the roll positions accordingly. Reassessing and realigning periodically during machine runs ensures that the product profile remains consistent and meets the desired specifications. Proper training for operators on identifying and correcting misalignment issues can significantly enhance machine performance and product quality.

Solutions for Material Feeding Issues

Material feeding problems can disrupt the entire roll forming process. Issues like material jamming, inconsistent feeding speeds, or kinks in the metal strip can be mitigated by ensuring the material is properly prepared and using suitable feeding techniques. Regularly clean and lubricate the feeding mechanisms and guide rolls to facilitate smooth metal passage. Employ systems to monitor and control the feeding speed, ensuring it aligns with the rolling speed of the machine. Implementing these solutions helps in reducing downtime and maintaining steady production quality.

Identifying and Fixing Surface Defects

Surface defects in the final product can arise from various factors, including incorrect roll pressure or material impurities. Regular inspection for scratches, dents, or other surface anomalies during the setup phase is crucial. If defects are detected, adjust the roll pressure and alignment, and ensure the material is clean and free from debris before feeding it into the machine. Employ quality control systems such as surface defect detectors to continuously monitor and identify defects, enabling quick corrections and ensuring high-quality outputs.

Maintenance Tips for Optimal Performance

Regular Inspection Procedures

Routine inspections are vital for the optimal performance of a roll forming machine. Schedule regular checks of all machine components, including rollers, bearings, and drive systems. Inspect for any signs of wear, corrosion, or damage, and replace worn parts immediately. Use diagnostic tools to assess the condition of internal components and perform preventive maintenance. Keeping a detailed log of inspection results and maintenance activities helps in tracking machine health and ensuring consistent performance.

Lubrication and Cleaning Practices

Proper lubrication and cleaning are essential for minimizing wear and tear on the roll forming machine. Apply the recommended lubricants to moving parts like rollers and bearings to reduce friction and prevent overheating. Clean the machine regularly to remove metal shavings, dust, and other contaminants that can affect performance. Use appropriate cleaning agents and tools to maintain the machine in optimal condition. A well-lubricated and clean machine operates more smoothly, increasing efficiency and lifespan.

Enhancing Efficiency with Proper Settings

Optimizing Output Speed and Quality

Achieving the right balance between output speed and product quality is crucial for enhancing efficiency in roll forming. Adjusting the roll forming machine settings to optimize the speed without compromising on the quality requires meticulous calibration. Employ automated systems to monitor and adjust speed settings in real-time based on material properties and production requirements. Continuously reviewing performance data and making necessary adjustments helps in maintaining high production efficiency and superior product quality.

Techniques for Reducing Waste During Production

Minimizing waste during roll forming not only increases production efficiency but also reduces material costs. Implement precise material cutting and measuring techniques to ensure accurate dimensions and reduce excess. Regularly calibrate the cutting systems and employ waste management strategies to recycle scrap metal. Training operators on efficient material handling and scrap reduction techniques helps in achieving a more sustainable production process and optimizing resource utilization.

In summary, XINBO is a company that offers custom services with a focus on efficient design, competitive pricing, short delivery times, and stringent quality inspection. Customers can rely on XINBO to provide them with high-quality products that meet their specific requirements.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia