How Does a Dual Running CU Channel Roll Forming Machine Work?

What is a Dual Running CU Channel Roll Forming Machine?

Definition and Purpose

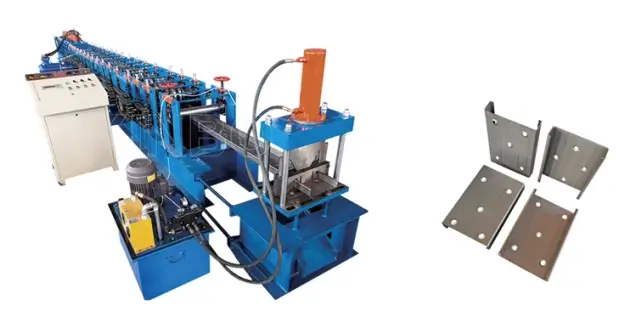

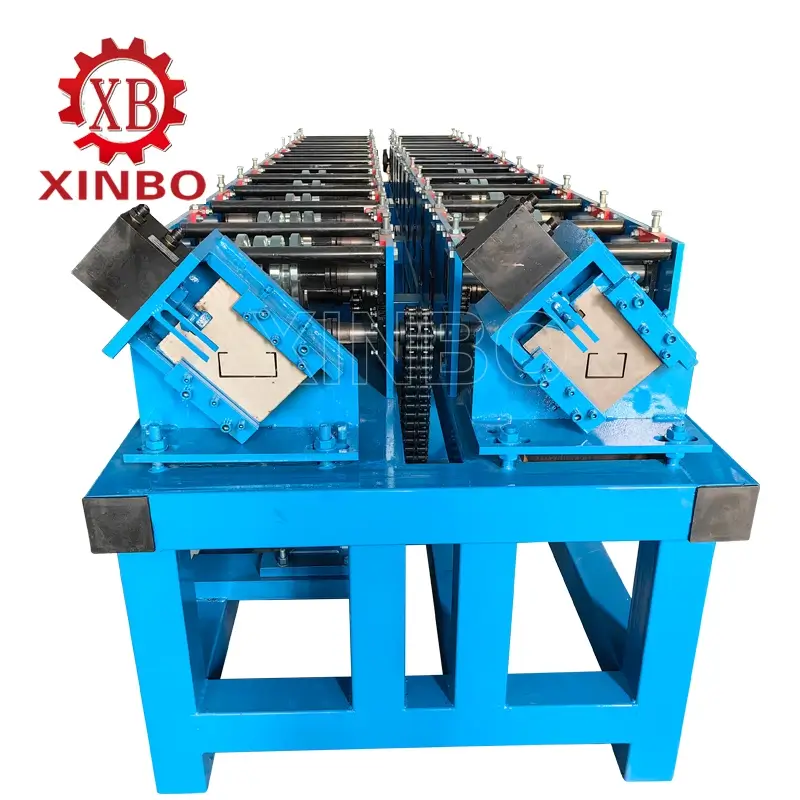

The Dual Rolling CU Channel Forming Machine is a cutting-edge device crafted to turn metal sheets into CU-shaped channels efficiently and effectively for applications in construction, as well as automotive and manufacturing sectors because of their durability and flexibility in use cases. It functions by guiding metal sheets through a set of rollers that mold the material into the shape gradually. Its ability to run operations permits the production of two-channel sizes or types simultaneously which boosts productivity levels significantly.

Components of the Machine

The Dual Running CU Channel Roll Forming Machine consists of parts.

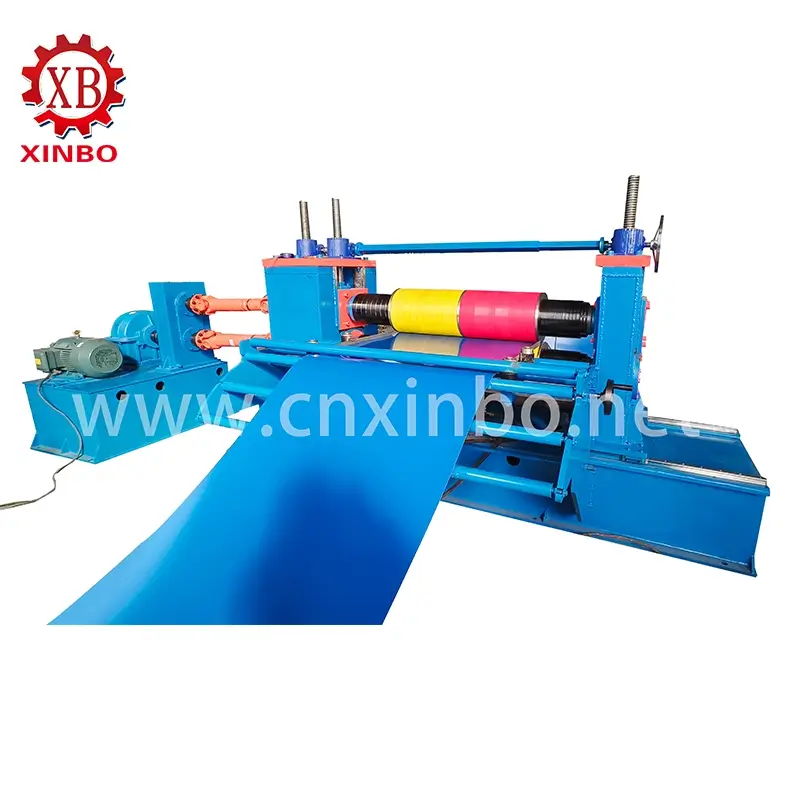

1.Manual Decoiler: This part holds and unwinds the metal coil, preparing it for processing.

2.Feeding Platform: It guides the metal sheet into the roll-forming section.

3.Main Roll Forming Machine: Equipped with multiple roller stations, it shapes the metal sheet into a CU channel.

4.Automatic Cutting System: This system precisely cuts the formed channels to specified lengths.

5.Hydraulic Station: Powers the cutting mechanism and other hydraulic functions within the machine.

6.Computer Control Box: Offers control over machine operations, ensuring precision and customization.

7.Finished Panel Receiving Table: Collects and organizes the completed channels for easy handling.

How Does the Dual Running Process Operate?

Step-by-Step Process

The process starts by placing a metal coil onto the decoiler before feeding the sheet into the machine using the feeding platform. As it moves through the roll-forming section. Passes through various roller stations consecutively bending and molding it into a CU channel shape.

Roll Forming Technique

The process of roll forming includes the bending of a strip of sheet metal using a sequence of rollers that each serve a unique purpose, in shaping the material. Having two sets of rollers running simultaneously through the running feature enables the production of two profiles concurrently while maintaining both speed and quality standards.

Cutting and Finishing Stages

After the channels are created and shaped according to the required lengths, at the automated cutting system; the hydraulic station is responsible, for ensuring an operation during this cutting phase. Thee finished channels are then moved to the designated panel collection table for handling or shipment.

What Are the Advantages of Using This Machine?

Efficiency and Productivity

The Double Operation CU Channel Rolling Machine greatly enhances efficiency by enabling the manufacture of two profiles at once. This decreases the time lost when switching between setups, for varied channel designs. I ts automated mechanisms guarantee velocity and precision resulting in reduced wastage and increased output capacity.

Quality and Consistency

With technology in play, this device ensures noticeable results with sizes and structural features across all output channels. Its precise computer-managed functions guarantee that every channel complies with industry norms without the need, for manual adjustments.

For details, about roll-forming machinery such as this model check out XINBO MACHINE MAKING CO., LTD. recognized for its cutting-edge approach, to crafting solutions customized for various industrial requirements.

Explore their Dual Running CU Channel Roll Former showcasing top-notch design and efficiency to meet the needs of manufacturing requirements.

Why Choose XINBO MACHINE MAKING CO. LTD for Your Roll Forming Needs?

Company Overview and Expertise

In the realm of roll-forming equipment expertise with XINBO MACHINE MAKING CO., LTD is a pioneering force in innovation and excellence in quality products for the industry sector they served diligently over the years giving rise to their reputation for producing high-performing machinery customized to suit a wide array of industrial needs showcased through their extensive range of cutting edge roll forming machines integrated with advanced technology solutions.

In everything XINBO does for its customers shows a focus on quality and a drive for customer happiness and ongoing progressions in their products and services they provide beyond machinery but comprehensive solutions that boost productivity and effectiveness, in manufacturing operations Their accomplished team of engineers collaborates closely with customers to grasp their unique requirements guarantee each machine is tailored for top-notch performance.

Discover the offerings of XINBO MACHINE MAKING CO., LTD to enhance your production capabilities with their cutting-edge solutions.

Product Offerings and Custom Solutions

At XINBO company they have a variety of roll forming machines, for purchase; one of their models is the Dual Running CU Channel Roll Forming Machine that showcases their dedication to advanced technology and precise craftsmanship, in manufacturing equipment of top-notch quality capable of crafting different profiles consistently.

XINBO not only offers products but also provides customized solutions designed to meet the specific needs of different industries in mind. If you’re looking for machinery that fits channel sizes or caters to applications XINBO’s team is capable of creating and fabricating equipment that aligns perfectly with your precise requirements.

What Should You Consider When Operating a Dual Running CU Channel Roll Forming Machine?

Safety Precautions

To operate a Dual Running CU Channel Roll Form Machine safely it is crucial to follow safety guidelines. Ensure that all operators receive training, in machine operation and are knowledgeable, about risks. Regularly checks safety barriers and emergency stop mechanisms to avoid accidents ts. All personnel engaged in the operation should wear protective equipment (PPE) including gloves and goggles.

Training and Skill Requirements

To ensure optimal performance levels and safety standards in the workplace operators should undergo training, in machine technicalities and safety protocols. Training sessions should encompass machine configuration, operation techniques, troubleshooting methods, and maintenance protocols. Having operators is essential, for sustaining productivity levels and upholding a work environment.

How Can You Maximize the Benefits of Your Machine?

Regular Maintenance Practices

Regular upkeep plays a role, in extending the longevity of your Dual Running CU Channel Roll Forming Machine. Establishing a routine for examining parts, like rollers, hydraulics systems,s, s, and control panels is crucial. Keep the moving components lubricated to minimize damage and promptly tackle any problems to avoid expensive downtimes.

Upgrading and Technology Integration

Keep up with the advancements by incorporating new functions into your current equipment setup. Enhancing software systems could boost accuracy, in control mechanisms. Introducing automation features may increase effectiveness. Collaborating with industry leaders guarantees access to state-of-the-art innovations that will help you stay competitive in your field.

To sum up the discussion, choosing to invest in a Dual Running CU Channel Roll Forming Machine from XINBO MACHINE MAKING CO., LTD not only enhances production capabilities but also guarantees top-notch results using cutting-edge engineering solutions. Emphasizing safety measures alongside training sessions and regular maintenance checks along with staying up to date with enhancements will help you maximize the advantages provided by this advanced equipment for your manufacturing requirements.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia