How Do Automatic C U Steel Channel Machines Boost Productivity and Cut Costs?

Manufacturers are constantly in need of ways to increase productivity, lower costs, and maintain the accuracy of production processes within the fast-moving metal fabrication industry. Among the most important technological advances within the steel industry is the Automatic C U Steel Channel Machine. These machines are designed to optimize production workflows and offer cost-effective solutions for fabricators. In this article, we will explore how automatic C U steel channel machines work, their key benefits, and why they are crucial in boosting productivity and cutting costs in the manufacturing sector.

What Are Automatic C U Steel Channel Machines?

Introduction to C U Steel Channels

C U steel channels are in wide use in the construction and manufacturing industries for framing, support structures, and other critical applications. These steel profiles, usually in the shape of a “C” or “U,” are used for their strength, durability, and versatility. The accuracy of the manufacturing of these steel channels is very important to guarantee structural integrity and meet the standards of the industry.

The Role of Automatic C U Steel Channel Machines

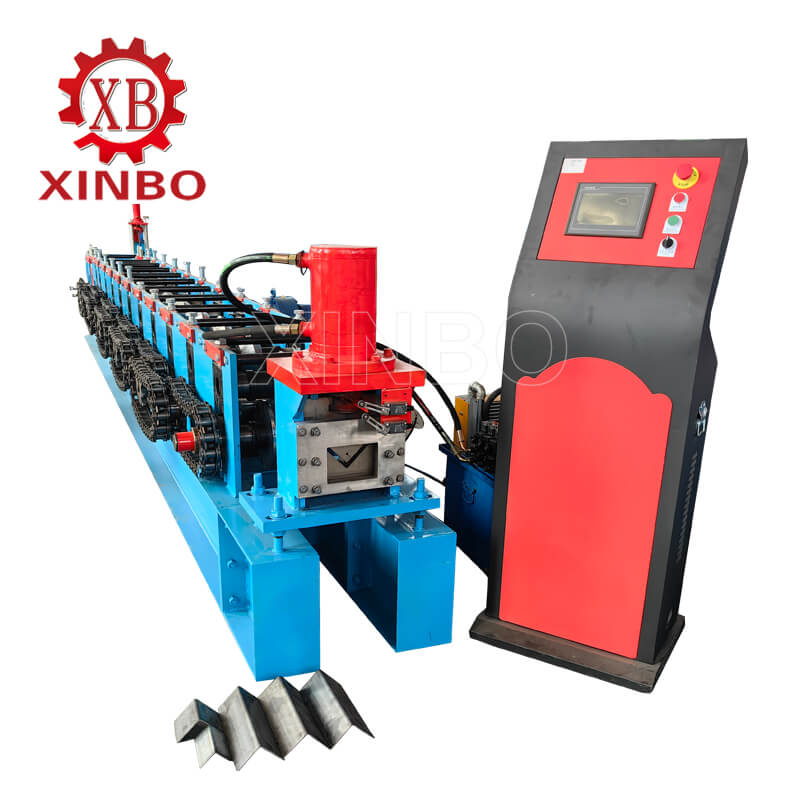

An Automatic C U Steel Channel Machine is a sophisticated machine that can provide these profiles with high accuracy and efficiency. Unlike traditional machines that necessitate manual changes of sizes and adjustments, automatic machines would allow for quick-size adjustments with no stoppages in the production process. It is such an automatic changing of sizes that is quintessential in achieving efficiency gains in modern times.

How Do Automatic C U Steel Channel Machines Work?

Fully Automatic Size Adjustment

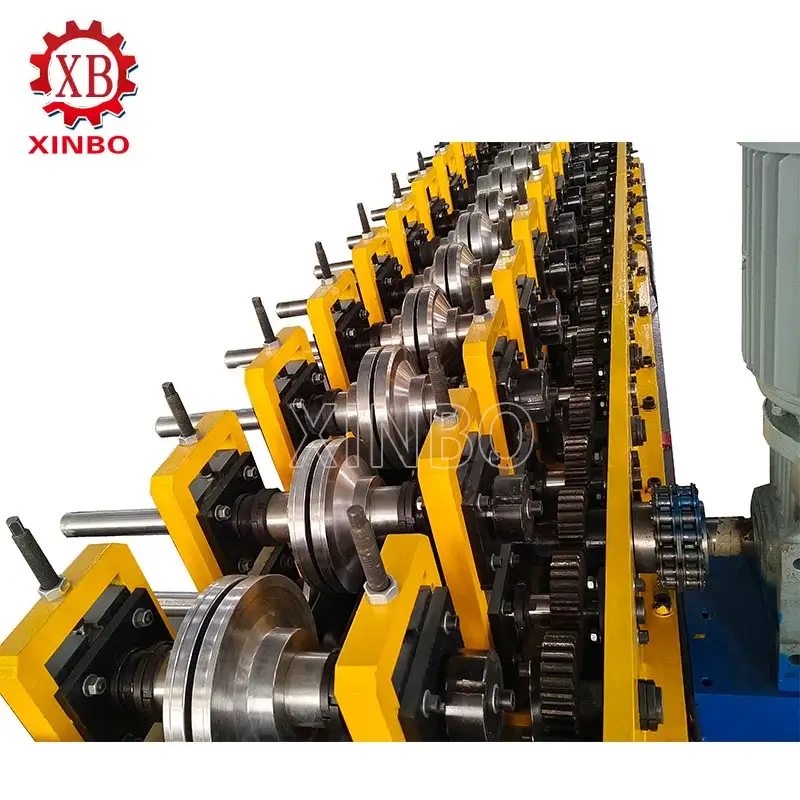

One of the most striking features of the Automatic Sizes Changing C U Steel Channel Machine is its ability to automatically change size. This is achieved by using advanced PLC (Programmable Logic Controller) and a touch screen control panel, through which operators input the desired channel size. The machine can then rapidly adjust the rollers and cutting systems to match the new specifications, reducing downtime and increasing throughput.

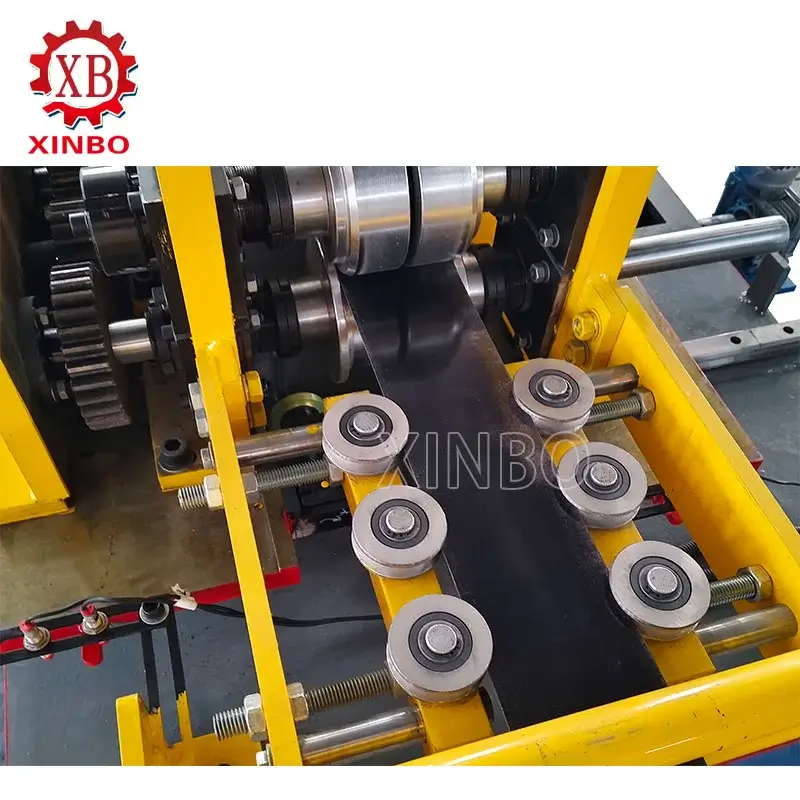

Material Processing and Cutting

The machine processes GI strip coils (Galvanized Steel) or PPGI strip coils (Pre-painted Galvanized Steel). This is processed without deviation or inaccuracy in various size variations through the incorporation of an automatic size change-over system. The machine also involves a hydraulic cutting profile that provides clean cuttings accurately at high speeds.

Speed and Efficiency

Automatic C U Steel Channel Machines are designed for high speeds, usually with production rates of up to 25 meters per minute. This level of speed coupled with the ease of automatic size changes makes these machines quite efficient for high-volume production environments. With such great speeds, manufacturers can fulfill the increasing demand for quality steel profiles without losing any productivity.

Advantages of Automatic C U Steel Channel Machines in Steel Fabrication

High Productivity with Quick Turnarounds

Another big advantage of the employment of automatic steel channel machines is that they reduce production time. This is because manufacturers are able to change sizes automatically without necessarily reducing speeds, which enables them to make a wide variety of products without having to stop and reset the machine. It results in faster turnaround times that allow companies to fulfill orders quicker and more efficiently.

Cost Reduction Through Labor Savings

Conventionally, size variations in steel fabrication were achieved by manual changes, which consumed a lot of time and required much labor. Automatic size-changing machines enable manufacturers to minimize the use of labor and hence save on labor costs to a great extent. Automation of the machine reduces human errors and requirements of skilled operators to a minimum, hence easier operation with minimal errors in production.

Reduced Material Waste

Material Waste Optimization: Automatic C U steel channel machines are designed to use materials efficiently. With proper cuttings and regulation of the flow of materials, wastes are reduced, thereby making sure that each piece of steel is used effectively. This helps not only in being environmental-friendly but also contributes towards reducing material costs in the long run.

Consistent Quality and Precision

With the C U steel channel machine being highly automated, each and every product is exactly the same in size and shape. This means that the quality is always the same for all batches, meeting the standards set by the industry and the customers. Precise steel channels are needed in industries where structural integrity is important, such as in construction.

Key Features of the XinBo Automatic Sizes Changing C U Steel Channel Machine

XinBo Automatic Sizes Changing C U Steel Channel Machine epitomizes yet another leap in metalworking. Following are the salient features that make the above machine a must for the latest production:

Fast and Easy Size Adjustments

This machine allows for fast size changes without requiring the production to stop; therefore, manufacturers can easily run different sizes with very minimal stops. The settings are also easy to change through a friendly touch screen by the operators.

High Efficiency and Customization

XinBo Machine Provides High Speed Up to 25 meters a minute, making the manufacturing a lot in very less time. Besides, this could be designed based on specific productions, and that can be very helpful for any manufacturer through adjusting the thickness, width, and other parameters to different requirements.

Durable and Reliable Construction

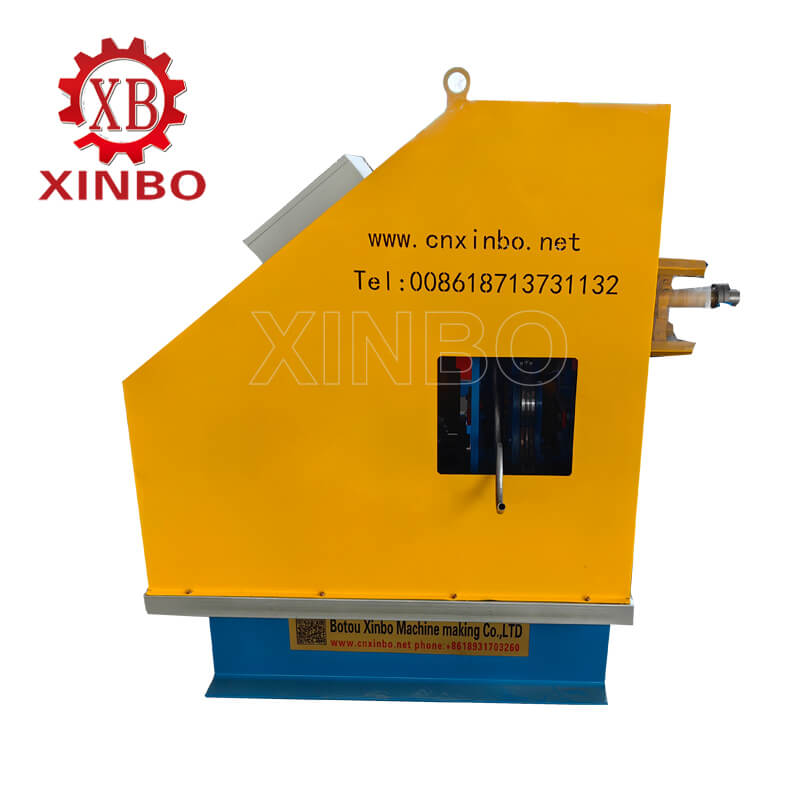

The XinBo C U steel channel machine is constructed with a steel plate welded box frame to withstand heavy-duty use in an industrial environment. The rollers are manufactured from 45 steel, heat-treated, and hard-chromed for increased durability and reliability over time.

PLC Control for Precision

The machine features a PLC control system that ensures precise adjustments for smooth operations in every step of the manufacturing process. This system will also provide real-time feedback to operators, making performance tracking easier and allowing for quick adjustments where necessary.

Energy and Cost Efficient

The XinBo machine ensures minimal consumption of energy with higher returns in output. These are cost-effective machines that reduce operation cost for the manufacturer while ensuring ability to meet customer demand within their budgets.

Why Choose XinBo for Your Steel Channel Machine Needs?

XinBo, founded in 2014, specializes in the production of professional and advanced roll forming machines with the addition of other steel-processing machinery. The company assures top quality, innovative technology, and customer satisfaction.

Competitive price, Custom Service

XinBo provides custom solutions for specific needs of all customers. Due to the available engineers and designers, detailed drawings can be designed and customized machines built by the company itself. Having its own in-house production and CNC machining, it has the ability to keep the prices competitive as well as to a quality standard.

Short Delivery Time and Quality Assurance

XinBo is committed to delivering machines quickly and reliably. Their short delivery time and three-step quality inspection process ensure that every machine is tested thoroughly before shipment. This ensures that customers get fully functional, high-performance machines with no delays.

Global Reach and Excellent Support

With a growing presence in Europe, the UK, and Canada, XinBo is well-equipped to serve international customers. Their professional customer service and after-sales support ensure that clients get the help they need for installation through ongoing maintenance.

Contact XinBo for the Best Automatic Sizes Changing C U Steel Channel Machines

Investing in the XinBo Automatic Sizes Changing C U Steel Channel Machine will help your business achieve higher productivity, reduced costs, and improved precision. To learn more or request a quote, reach out to XinBo’s dedicated team today:

- Email:serena@cnxinbo.net

- Phone:+86 18031857025

XinBo’s professional design, manufacturing, and support teams are ready to assist you in meeting your production goals with the most advanced technology in the steel channel fabrication industry.

In short, automatic C U steel channel machines have the power to enhance productivity and cut costs in steel fabrication. Investment in advanced machinery such as XinBo Automatic Sizes Changing C U Steel Channel Machine can assure manufacturers of faster production, lower labor costs, consistent quality, and reduced material waste. Embrace the future of steel channel manufacturing and stay competitive in today’s fast-paced market.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia