How a Shutter Door Machine Works: A Comprehensive Guide

What is a Shutter Door Machine?

A shutter door machine is an advanced industrial apparatus engineered for the precise fabrication of shutter doors. By automating critical stages such as cutting, rolling, and assembly, these machines significantly enhance production efficiency. Shutter doors are prevalently employed in commercial and industrial environments owing to their robustness, security features, and practicality. Acquiring comprehensive knowledge of the operational mechanisms of a shutter door machine is crucial for businesses aiming to optimize production efficacy and elevate product quality.

Key Components of a Shutter Door Machine

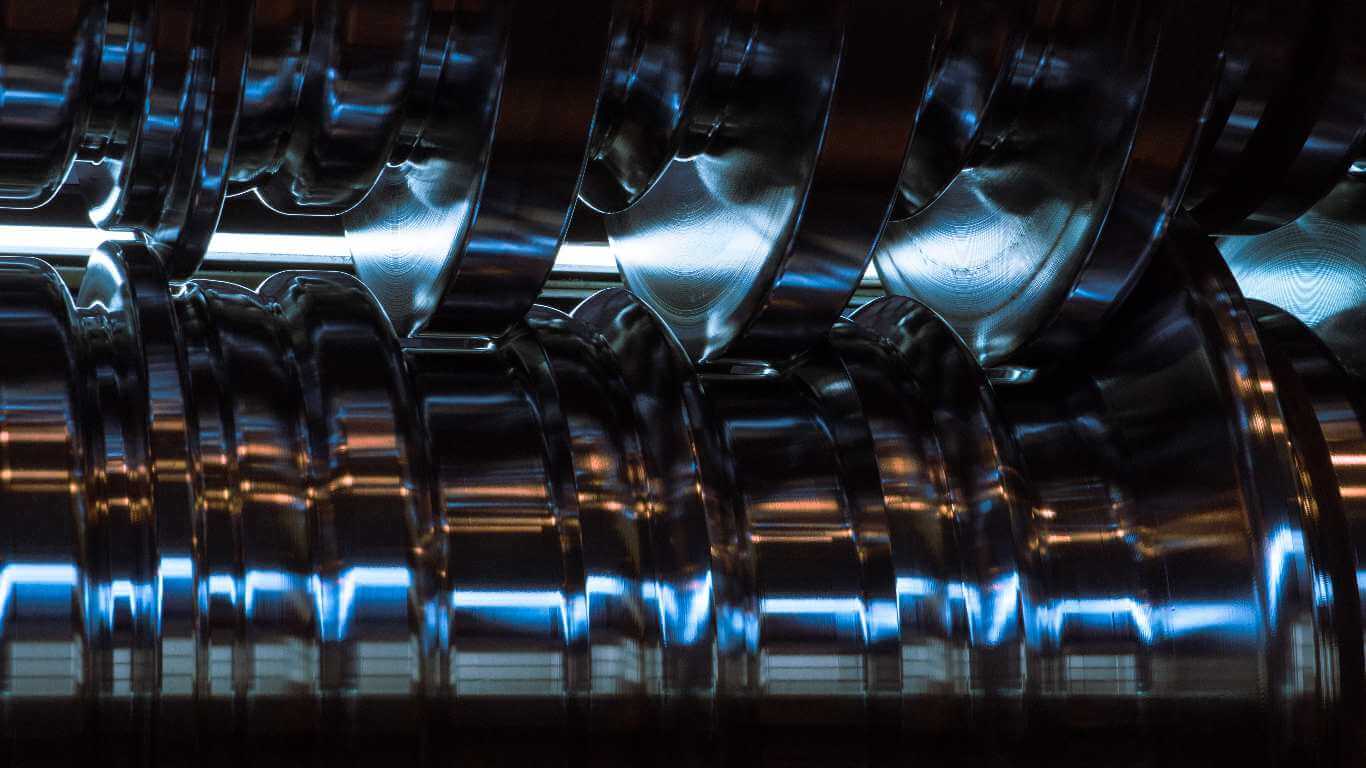

Rollers and Spindles

Rollers and spindles play a pivotal role in the operation of a Shutter Door Machine, being essential for the precise shaping and forming of metal sheets into specified shutter door profiles. The rollers engage with the metal sheet, guiding it through the machine, while spindles ensure proper alignment and maintain consistent tension. The utilization of high-quality rollers and spindles is imperative for achieving smooth, accurate formation of shutter doors, thereby significantly elevating overall production quality.

Electrical Control Panel

The electrical control panel serves as the brain of a Shutter Door Machine. It houses all the electronic components and software that govern the machine’s operations. Operators use the control panel to input specifications, adjust settings, and monitor production. Advanced control panels often feature touch screens, user-friendly interfaces, and programmable logic controllers (PLCs), enabling efficient and reliable machine performance.

Cutting Mechanism

The cutting mechanism in a shutter door machine is designed to precisely cut metal sheets to the required dimensions. Depending on the model, this component can be either mechanical or hydraulic. Accurate cutting is crucial to ensure the shutter doors fit perfectly into their frames. With sharp and well-maintained cutting tools, material wastage can be reduced by up to 15%, significantly boosting production efficiency.

How Does a Shutter Door Machine Work?

Material Feeding Process

The material feeding process is the initial stage in the operation of a Shutter Door Machine. Metal sheets or coils are fed into the machine, either manually or through an automated system. Proper material feeding is crucial for maintaining continuous and uninterrupted production. Feeding systems may include grippers, conveyors, and feed rollers, all of which work in unison to guide the material accurately into the machine.

Rolling and Cutting Process

Once the metal sheet is fed into the Shutter Door Machine, it undergoes the rolling and cutting process. As the sheet passes through the rollers and spindles, it is shaped and formed into the desired profile. Following this, the cutting mechanism trims the sheet to the exact required dimensions. Ensuring precise rolling and cutting is vital for producing high-quality shutter doors that meet industry standards and customer specifications.

Final Assembly Process

The final stage in the operation of a Shutter Door Machine is the assembly process. Here, the cut and formed metal sheets are assembled to create the complete shutter door. This process may involve additional operations such as riveting, welding, and painting, depending on the specific design and requirements. High-quality assembly ensures the durability and functionality of the shutter doors, making them suitable for heavy-duty applications.

Types of Shutter Door Machines

Manual Shutter Door Machines

Manual shutter door machines require human intervention for most of their operations. Operators need to manually feed the material, handle the rolling and cutting processes, and assemble the final product. While these machines are generally less expensive, they also require more labor and can be slower in production. They are suitable for small-scale operations or businesses with lower production demands where the focus is on flexibility and customization.

Semi-Automatic Shutter Door Machines

Semi-automatic shutter door machines combine elements of manual and automated processes. In these machines, some stages, such as material feeding or cutting, may be automated, while others still require human intervention. Semi-automatic machines offer a balance between efficiency and cost, making them a good choice for mid-sized operations. They provide decent production rates and consistent quality without the need for significant manpower, thereby reducing labor costs.

Fully Automatic Shutter Door Machines

Fully automatic shutter door machines are the epitome of production efficiency, featuring advanced technologies that automate the entire production process. From material feeding to rolling, cutting, and assembly, every stage is controlled by the machine, requiring minimal human intervention. These machines are ideal for large-scale operations where high production volumes and consistency in quality are paramount. While the initial investment is higher, the long-term benefits in terms of efficiency and reduced labor costs often justify the expense.

Benefits of Using a Shutter Door Machine

Efficiency in Production

Using a shutter door machine significantly enhances production efficiency. Automation accelerates the manufacturing process, allowing businesses to produce a larger number of shutter doors in a shorter period. This is particularly beneficial for meeting high-demand periods without sacrificing quality. Additionally, these machines often come with features that minimize downtime and maintenance, enabling continuous operation.

Cost-Effectiveness

Shutter door machines offer substantial cost savings over time. Automation reduces the need for manual labor, lowering labor costs and minimizing human errors that could lead to material wastage or rework. Furthermore, the precision of these machines ensures optimal use of materials, thereby reducing material costs. The initial investment in a shutter door machine is often offset by the long-term savings in labor and materials.

Consistency in Quality

One of the primary advantages of using a shutter door machine is the consistency in the quality of the output. Automated machines follow exact specifications and operate with high precision, ensuring that every shutter door produced meets the required standards. Consistency in quality is crucial for maintaining customer satisfaction and building a strong reputation in the marketplace.

Applications of Shutter Door Machines

Industrial Uses

Warehouses

In industrial settings, shutter doors are essential for securing large openings in warehouses. Shutter door machines enable the mass production of robust and durable doors that can withstand harsh industrial environments. The automation of the production process ensures that these doors meet the stringent safety and security standards required in warehouse applications.

Manufacturing Plants

Manufacturing plants also benefit from shutter doors produced by automated machines. These doors provide an effective barrier against unauthorized access and environmental contaminants like dust and debris. Shutter door machines ensure that doors are produced to precise specifications, enhancing the operational efficiency and safety of manufacturing facilities.

Commercial Uses

Retail Outlets

Retail outlets use shutter doors to secure premises during non-operational hours. Shutter door machines allow for the rapid and efficient production of doors that can be customized to fit various storefront designs. The consistency in quality ensures that these doors offer reliable security and aesthetic appeal, both of which are critical for retail environments.

Parking Garages

Parking garages utilize shutter doors to control access and enhance security. The robustness and reliability of shutter doors produced by automated machines make them ideal for this application. The ability to customize dimensions and designs ensures that the doors fit perfectly and operate smoothly, contributing to the overall functionality of parking facilities.

Factors to Consider When Choosing a Shutter Door Machine

Production Requirements

When selecting a shutter door machine, one of the primary considerations should be your production requirements. Evaluate the volume of shutter doors you need to produce and the speed at which you need them. This will help determine whether a manual, semi-automatic, or fully automatic machine is most suitable for your operation.

Budget Constraints

Budget constraints are another critical factor. While fully automatic machines offer the highest efficiency and production capabilities, they also come with a higher price tag. Businesses need to balance their budget with their production needs to find a machine that offers the best return on investment.

Maintenance and Support

Finally, consider the maintenance and support services available for the machine. Regular maintenance is essential for ensuring the longevity and optimal performance of a Shutter Door Machine. Choose a machine from a reputable manufacturer that offers comprehensive support services, including training, technical assistance, and readily available spare parts.

Understanding the intricacies of how a Shutter Door Machine works and what factors to consider can significantly enhance the efficiency and quality of your shutter door production process. Whether you are looking to upgrade your existing setup or start a new production line, these insights can serve as a valuable guide in making informed decisions.

XINBO is an excellent Shutter Door Machine manufacturer.

XINBO‘s Shutter Door Machine is a specialized machinery designed for the manufacturing of shutter doors. It is a product offered by XINBO, a Chinese manufacturer established in 2014. The company is known for its commitment to quality assurance, with a team of professional designers, producers, and workers ensuring the highest standards.

The Shutter Door Machine incorporates new and innovative technology, catering to the specific requirements of customers in Europe, the UK, and Canada. It is designed to produce roll-formed shutter doors, providing durability and functionality. XINBO also offers a standard class option for normal consumption.

The machine is equipped with advanced features and capabilities, allowing for seamless production of shutter doors. It is highly adjustable, enabling customization according to different sizes and thicknesses of metal sheets. With its precise engineering, the Shutter Door Machine ensures the production of high-quality and reliable shutter doors.

XINBO‘s Shutter Door Machine is a testament to the company’s dedication to providing efficient and cost-effective solutions for the manufacturing industry. With its expertise in cold rolling machines and special designs, XINBO ensures that the machines can be easily transported in standard 40ft HQ containers, resulting in significant logistic savings for international clients.

In summary, XINBO’s Shutter Door Machine is a technologically advanced and versatile machinery designed for the production of high-quality shutter doors. It reflects XINBO’s commitment to innovation, customer satisfaction, and cost-effectiveness in the manufacturing industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia

-1.jpg)