Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

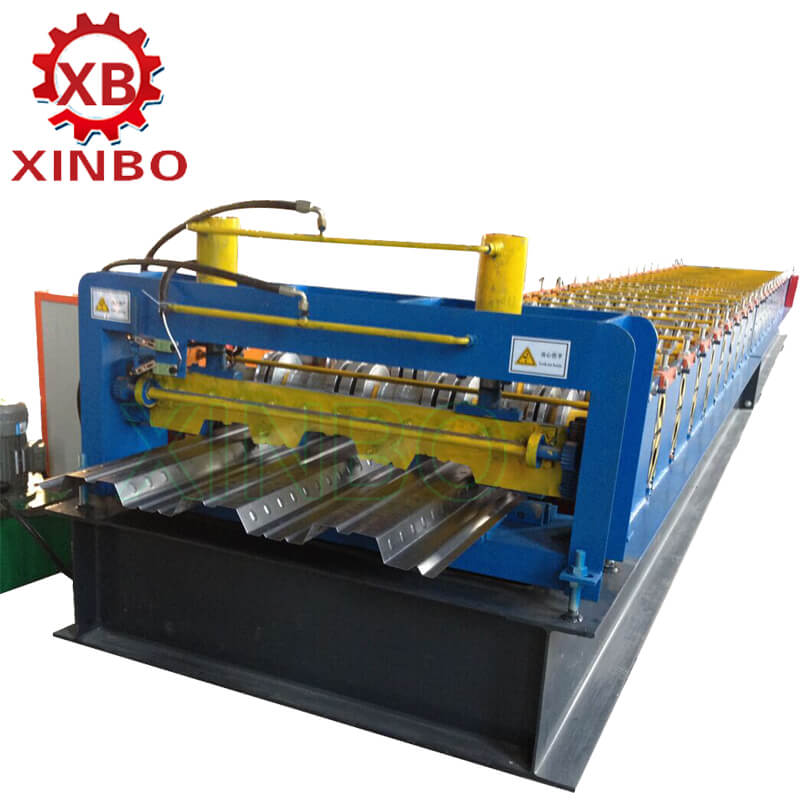

floor decking machine

Floor decking machinee, namely floor bearing plate production equipment, is used for molding floor bearing plates. The floor decking machine produced by the floor bearing plate machine has simple shape, large waviness and high strength. During installation, the spot welded reinforcing mesh is paved and combined with the on-site concrete pouring, with good adhesion. In high-rise buildings, the floor bearing plate can not only save the steel formwork but also reduce the floor bearing capacity. On the premise of reaching the same bearing capacity, it can reduce the amount of steel used in the project, thus saving investment. There are multiple models of floor bearing plate equipment, which are used to produce floor bearing plate products of different sizes.

Main structural features of floor support plate machine:

1. Simple structure and beautiful appearance. As the whole machine is of section steel structure and processed as a whole after welding, the structure is simple and reasonable, the storage capacity is strong, and the operation is stable and reliable.

2. Other important parts and components are equipped with high-quality accessories, which effectively ensures the performance of the equipment.

3. The full-automatic fixed length positioning cutting is adopted, and the plate shape head and tail are beautiful and neat.

4. The equipment is easy to install and operate.

5. The equipment has low noise, no pollution and low consumption.

The following is an introduction to each component of the machine:

Product parameters

|

No. |

Item |

|

|

1. |

Processing Material |

GI |

|

2. |

Input Width(mm) |

1000 |

|

3. |

Formed Width(mm) |

688 |

|

4. |

Processing Thickness(mm) |

0.8—1.0 |

|

5. |

Material of Rollers |

45# steel,with hard chrome coated |

|

6. |

Diameter of Shaft |

Ф80mm |

|

7. |

Production Speed |

8—10m/min |

|

8. |

Roller Driven |

Decelerating Motor+Chain Transmission |

|

9. |

Cutting Model |

Hydraulic Profile Cutting |

|

10. |

Length Measurement |

Encoder |

|

11. |

Control Style |

PLC |

|

12. |

Operation Model |

Button + Touch Screen |

|

13. |

Total Power |

5.5+5.5+4kw |

|

14. |

Voltage |

380V 50HZ or at buyer’s request |

|

15. |

Number of roller stations |

26 or as designing |

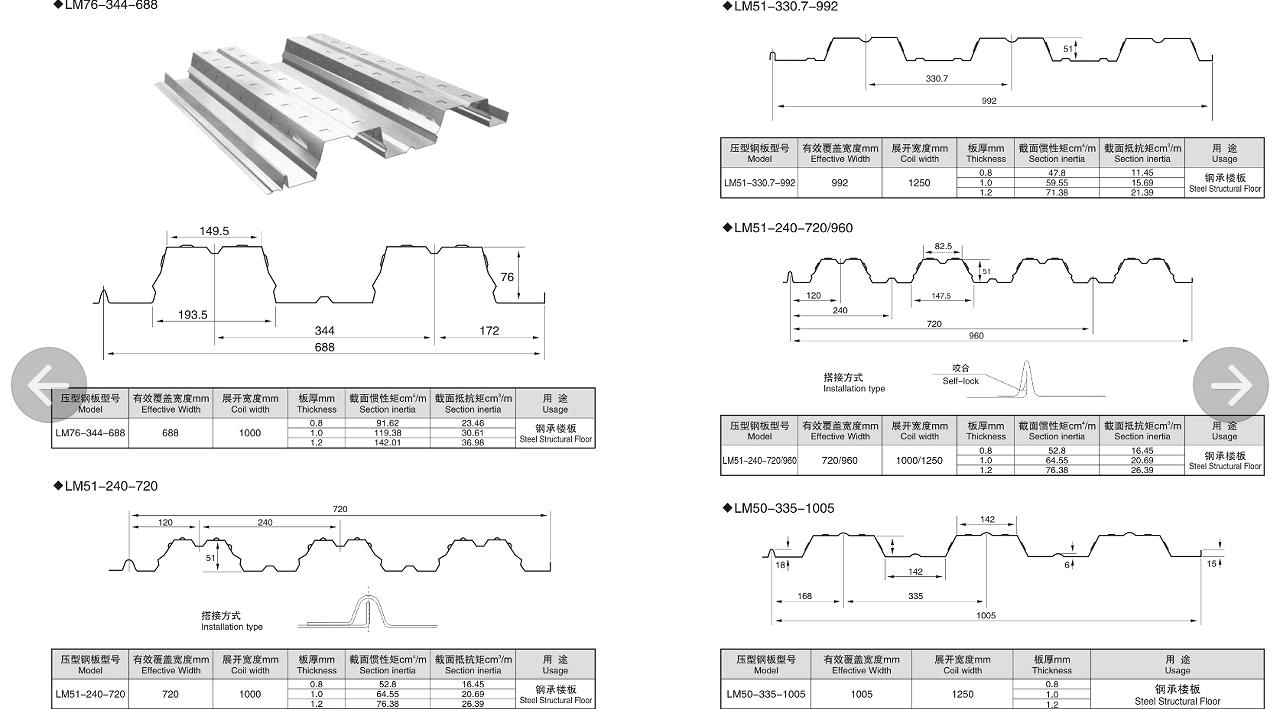

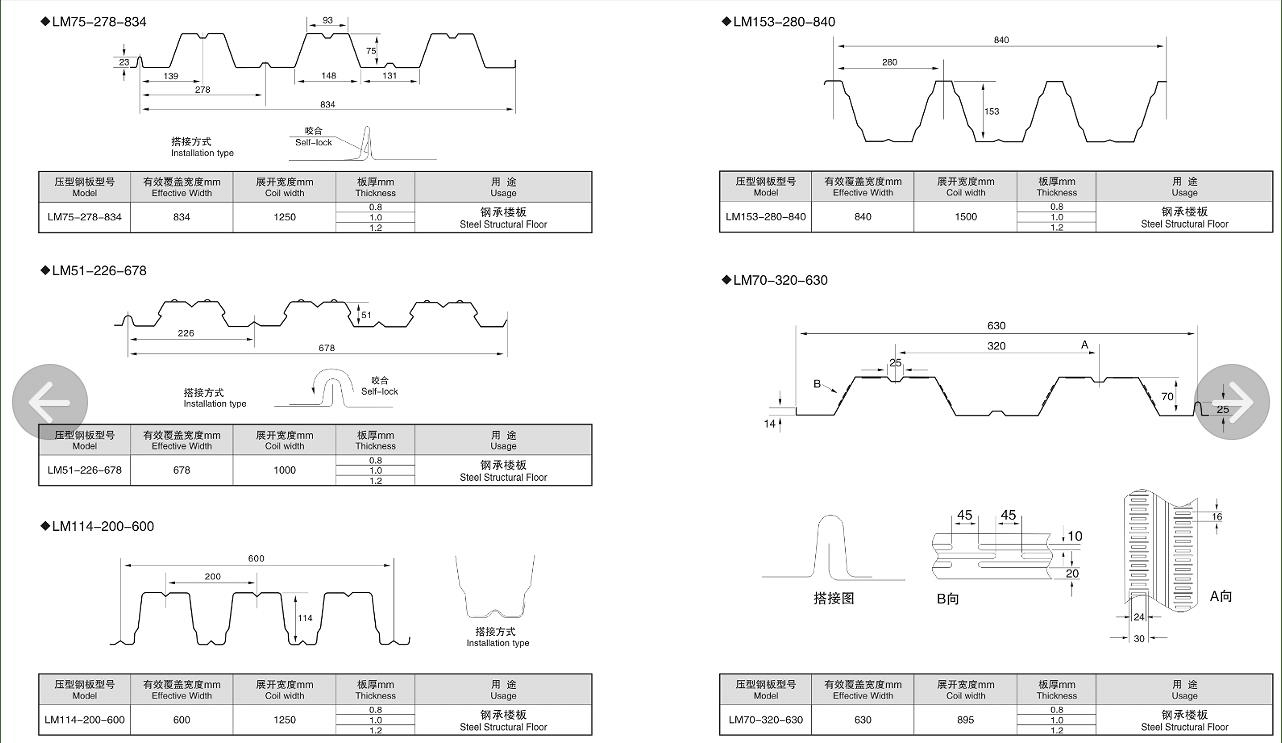

Drawings:

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→