Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

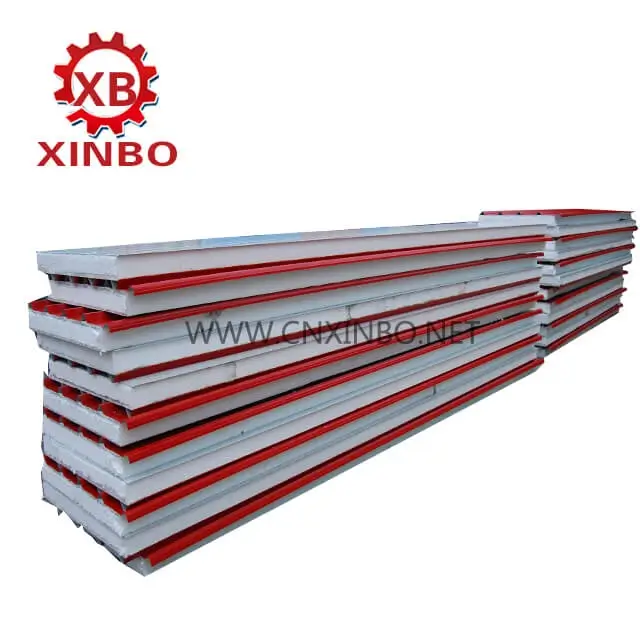

VIEW MORE→EPS sandwich panels are gaining popularity in contemporary construction work. The panels consist of a thin foam core, typically expanded polystyrene (EPS), between two metal sheets. They are used as walls, roofs, or partitions in a building. Their popularity is because they have superior heat insulation, are easy to install, and have superior durability.

In a bid to provide the mounting need for such panels, there are special machines which are EPS sandwich panel machines used by the manufacturers. With such machines, the entire process is made efficient, smooth, and economical. We will look at how the machines function, how important they are, and why Xinbo provides great custom-made solutions.

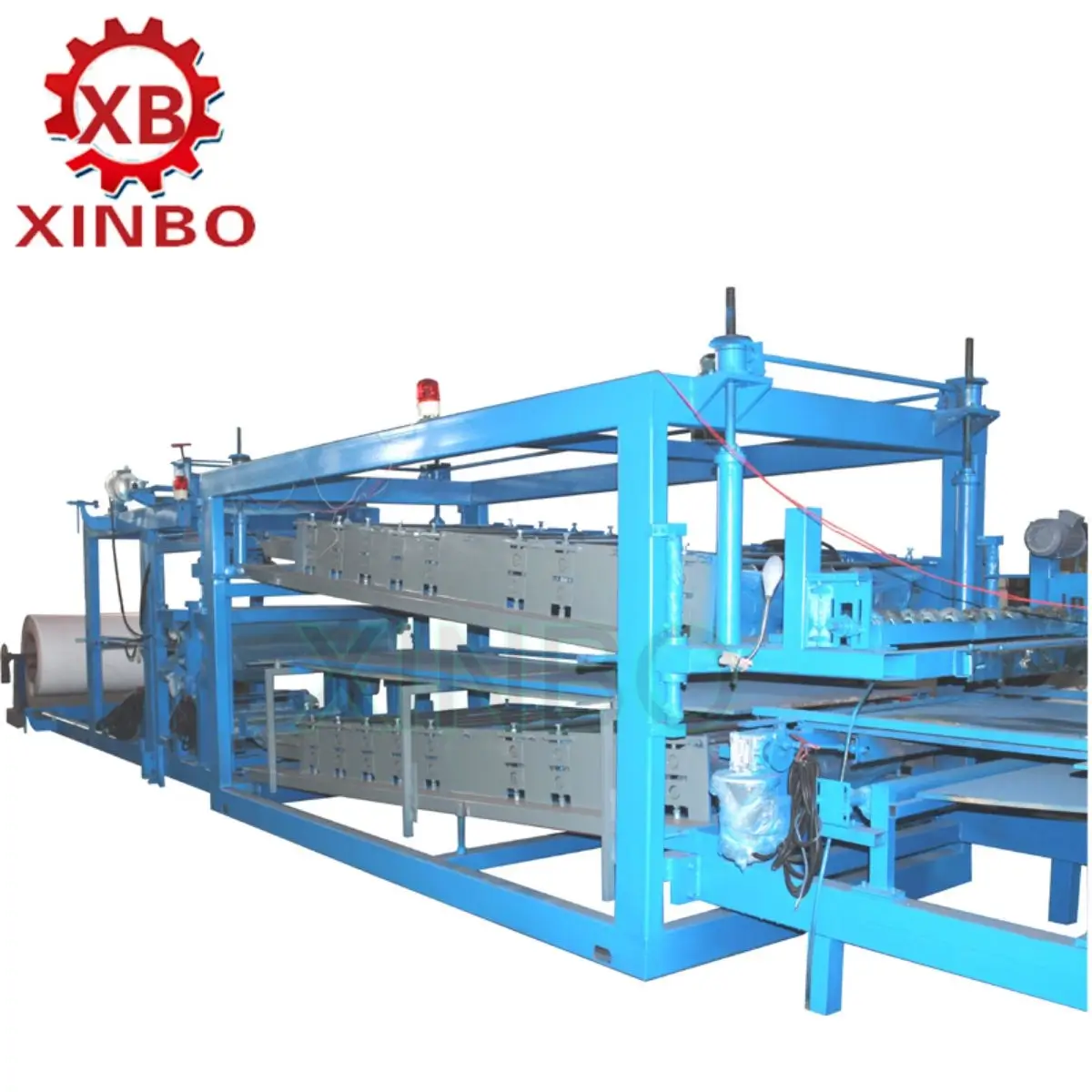

An EPS sandwich panel manufacturing machine is an automatic equipment utilized in manufacturing insulated panels for walls and roofs. It is a key equipment in modern prefabricated construction. The machine gives quality, consistency, and efficiency in panel manufacturing.

A standard eps sandwich panel production machine includes several critical parts. First, there is the metal sheet feeding mechanism. This system loads the outer layers of the panel. It then guides them into the production line. Next, a foam core integration system positions the EPS foam or rock wool between the metal sheets. Adhesive and pressing mechanisms subsequently bond the layers firmly.

The machine also features an automated control system. This system oversees temperature, speed, and pressure. It reduces human errors and guarantees uniform quality. The materials used—EPS foam, metal sheets, and sometimes rock wool—provide superior insulation and fire resistance. These qualities make them suitable for various structure types.

The process begins with loading metal sheets and foam core materials. The sheets move along the production line. Meanwhile, the core material is placed between them. Then, adhesive stations apply specialized glues to join the layers. After this, the panels are pressed and cured.

Once cured, the panels are cut to the required size. They are then stacked. The fully automatic eps sandwich panel production machine line ensures this process runs smoothly. It requires minimal human involvement. This increases output and lowers labor costs. Thus, it is a prudent choice for producers.

EPS sandwich panel machines are transforming how structures are constructed. They provide numerous advantages that traditional methods cannot compete with.

Creating panels manually is time-consuming. It often leads to mistakes and waste. With an eps sandwich panel making machine, producers can craft high-quality panels at speeds up to 20 meters per minute. A fully automatic EPS sandwich panel production machine line ensures each panel meets precise standards. This saves time. It also reduces waste and cuts overall production expenses.

These machines are highly adaptable. They can process various materials, such as EPS foam, rock wool, or hybrid cores. This makes them ideal for different construction needs. These include storage facilities, homes, or refrigeration units. Whether you are building a factory or a small modular residence, an eps sandwich panel machine can produce the necessary panels.

A primary benefit of using a china eps sandwich panel forming machine is reduced labor and material expenses. These machines use accurate measurements and automated systems. This minimizes waste. They also produce panels with excellent heat insulation. This supports energy-efficient designs. As a result, energy costs in buildings are lowered.

EPS sandwich panels are utilized in various structure types. Their lightweight nature and robust insulation make them an excellent choice in multiple settings.

In factories, storage facilities, and office spaces, these panels help regulate indoor temperatures. They also reduce energy consumption. The eps sandwich panel making machine factory models are designed to create panels with appropriate thickness and density. These are suited for large-scale industrial purposes. The panels are fire-resistant and soundproof. This makes them perfect for commercial buildings.

Prefabricated homes and modular residences benefit greatly from these panels. They are easy to transport and install. This reduces construction time. The eps sandwich wall panel machine is often used in housing projects where speed and insulation are crucial. These homes are built quickly. They are also safe and comfortable for residents.

Cleanrooms, laboratories, and refrigeration units require panels that resist moisture. They also need to maintain strict temperature controls. The rock wool eps foam sandwich wall panel production line machine produces panels ideal for such settings. These panels are hygienic and simple to clean. They help maintain a sterile environment.

Selecting the appropriate machine for your production needs is essential. Several factors should guide your decision when choosing from eps sandwich panel machine manufacturers.

First, assess the automation level. A fully automatic system provides greater speed and consistency. Output capacity is also crucial. Ensure the machine can meet your daily production requirements. Compatibility with materials like EPS and rock wool adds versatility. Reliable after-sales support is vital too. This includes setup and maintenance services.

Collaborating with experienced producers ensures you receive a high-quality machine. It also guarantees long-term support. Certified manufacturers with strong research and development teams offer advanced technology. They also provide more tailored options. For example, Xinbo’s china eps sandwich panel forming machine is renowned for delivering customized solutions. These meet specific project demands.

Xinbo stands out among eps sandwich panel making machine manufacturers. Its focus on customization and client support sets it apart.

Xinbo offers machines that can be adjusted for various panel sizes, core materials, and production speeds. Whether you need thick panels for refrigeration units or lightweight ones for modular homes, Xinbo can design a machine that perfectly suits your requirements.

From setup to technical guidance, Xinbo provides comprehensive support to its clients. Their fully automatic eps sandwich panel production machine line is user-friendly. It includes training and maintenance services. Ready to streamline your production? Contact Xinbo for a complimentary consultation!

A: Depending on thickness and materials, the machine can produce 10–20 meters of panel per minute.

A: Yes, most advanced machines are designed for multi-material production.

A: Regular tasks like lubrication, belt adjustments, and software updates keep the machine running smoothly.

A: Yes, Xinbo offers customizable machines for both small and large operations.

A: Consider your budget, daily output needs, and labor resources.

Want to cut construction time by 40%? Discover how Xinbo’s eps sandwich wall panel machine can revolutionize your workflow. Request a Quote Today.

The right machine isn’t just about speed—it’s about building smarter. Let Xinbo’s experts craft a solution tailored to your vision. Explore Custom Options or call +8618713731132 to launch your project!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→