Enhancing Roof Panel Quality with Advanced Corrugated Machines

How Do Corrugated Machines Improve Roof Panel Quality?

The Role of Corrugated Machines in Roofing

Corrugated machinery plays a role in improving the quality of roofing panels by ensuring their durability and precision through technology integration that streamlines production processes to meet high industry standards consistently.

– Precision in Design and Manufacturing

Attention to detail plays a role in providing top-notch roofing solutions that meet clients’ needs efficiently. Cutting-edge corrugated machines are integrated with systems that carefully oversee every step of the manufacturing process. Starting from the input of materials to the precise cutting of the end product, these machines guarantee that each roof panel is created with precision. The commitment to accuracy in both design and production results in top-tier roof panels that fit and deliver consistent performance over time.

– Consistency in Output and Quality

Ensuring consistency is crucial when manufacturing roofing materials. Corrugated machines are engineered to provide results to uphold a standard of quality for each roof panel. This uniformity helps reduce discrepancies and flaws that could potentially impact the durability and effectiveness of the structure builders and contractors can rely on the use of materials for their projects.

Key Features of Modern Corrugated Machines

Modern corrugated machines come equipped with a variety of functions that improve their effectiveness and flexibility making them essential instruments for crafting top-notch roof panels.

– Automation and Efficiency

Modern corrugated machines are known for their reliance on automation which boosts efficiency by handling production tasks automatically. Utilizing automated systems minimizes errors made by humans and quickens the pace of production while maximizing the use of resources. The outcome is heightened productivity levels without compromising on quality standards.

– Versatility in Material Handling

Modern corrugated machines have the advantage of being versatile as they can work with materials and adapt to thicknesses and profiles to create a variety of roof panels tailored to meet specific project needs and customer preferences effortlessly.

What Are the Benefits of Using Advanced Corrugated Machines?

The use of state-of-the-art corrugated equipment brings advantages that improve the strength and affordability of roofing panels.

Enhanced Durability of Roof Panels

Cutting-edge corrugated machinery plays a role in enhancing the longevity of roofing panels crafting items that can withstand an array of environmental obstacles.

– Resistance to Environmental Factors

Roof sheets made with cutting-edge corrugated equipment demonstrate durability, against elements like wind and rain well as changes in temperature conditions. This robustness guarantees that roofs stay undamaged and operational for periods of time safeguarding buildings effectively.

– Longevity and Maintenance Reduction

Sturdy roof panels require upkeep throughout their life span because of their durability and high-quality materials that contribute to repairs or replacements needed over time. This leads to cost savings for property owners in the long run.

Cost Efficiency and Time Savings

The cost savings and quicker project completion times are the results of the enhanced corrugated machines’ effectiveness.

– Reduced Waste Production

By improving how materials are used with cutting and shaping techniques advanced corrugated machines decrease the amount of waste generated. This helps cut down on material expenses and promotes manufacturing methods.

– Faster Production Times

The rapid pace at which sophisticated corrugated machinery functions facilitates completion of tasks leading to project delivery for manufacturers while maintaining high standards of quality and accuracy.

Why Choose XINBO MACHINE MAKING CO. LTD for Your Needs?

Opting for a trusted company such as XINBO MACHINE MAKING CO., LTD guarantees access to high-quality machinery customized to meet your roofing requirements.

Innovative Solutions for Roofing Industry

At XINBO MACHINE MAKING CO., LTD, we provide cutting-edge solutions tailored to meet the changing needs of the roofing sector.

– Cutting-edge Technology Integration

Their dedication to incorporating the technology into their products guarantees that customers get off-line machinery that can consistently produce outstanding results.

– Tailored Machine Configurations

At XINBO, we customize machine setups to meet the needs of each client guaranteeing that every customer gets equipment that’s ideal for their particular uses in the roofing industry.

Commitment to Quality and Customer Satisfaction

At XINBO MACHINE MAKING CO., LTD, we focus on ensuring top-notch quality and ensuring our customers are fully satisfied every step of the way. From the moment of purchase to post-installation support services.

– Comprehensive Support and Services

Their commitment goes beyond the provision of machinery as they provide a range of support services, such as maintenance training programs to ensure customers get the most out of their investments in XINBO’s top-notch equipment options.

– Proven Track Record in the Industry

In this industry, XINBO MACHINE MAKING CO., LTD has a proven history of satisfied customers worldwide ensuring dependable service based on extensive experience and expertise.

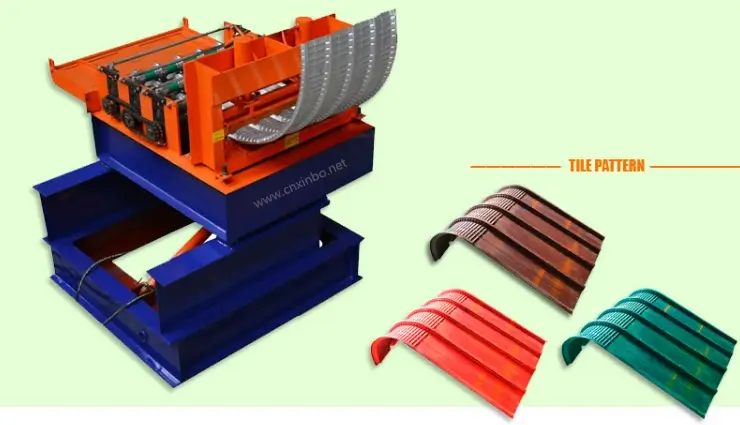

What Products Does XINBO Offer to Enhance Your Roofing Projects?

When looking to boost the quality of your roofing project outcomes in mind and diversify your options for roofing needs and requirements, XINBO MACHINE MAKING CO., LTD offers a variety of products tailored to these purposes with a focus being aimed at enhancing the effectiveness and longevity of roofing solutions They offer.

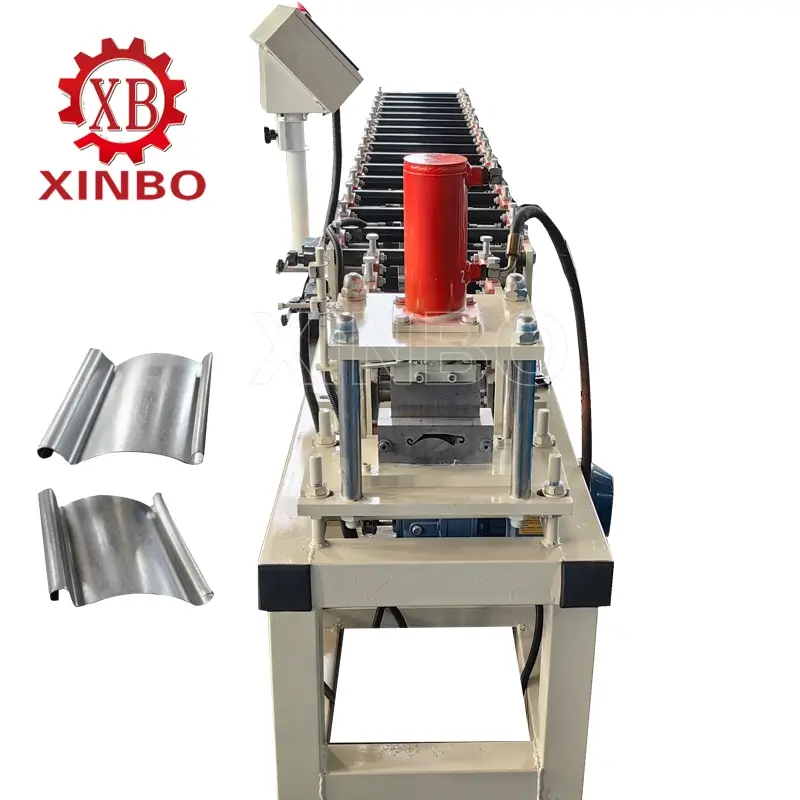

Corrugated Roll Forming Machine

The Corrugated Roll Form Machine stands out as a product in the XINBO’s range designed to create premium corrugated sheets for roofing endeavors.

– Features and Specifications

This device comes with high-tech capabilities to guarantee accuracy and uniformity, in manufacturing processes. It utilizes cutting-edge technology to shape corrugated sheets according to customer needs. The sturdy build of the equipment guarantees durability over time. Reduces the need for maintenance making it a cost-efficient option, for extensive production operations.

– Applications and Use Cases

The Corrugated Roll Formin Machine is highly adaptable, can be used for a range of purposes in creating roofing panels for both commercial and residential structures that can withstand different environmental conditions while also looking visually appealing. Its capability to tailor profiles and sizes allows for its use in a variety of projects.

How Can You Maximize the Potential of Your Roof Panels with XINBO’s Solutions?

In order to make the most of XINBO machinery capabilities for your roof panel production process improvement it is important to incorporate practices.

Strategies for Optimal Machine Utilization

Getting the most out of your rooftop solar panels goes beyond buying high-quality gear—it also involves implementing operational strategies.

– Regular Maintenance Practices

It’s important to maintain your corrugated machines to make sure they last long and perform well at the levels possible. Having a maintenance plan in place allows you to catch problems early on before they become major issues. This helps cut down on downtime and repair expenses. When you keep your machines in shape through maintenance you’re guaranteeing high quality results and increasing the life of your investment.

– Training for Operational Excellence

Ensuring your team receives training is crucial for reaching peak performance. Thorough training guarantees that operators can efficiently operate machinery to boost productivity and reduce mistakes. XINBO MACHINE MAKING CO., LTD provides training programs as a part of their customer service efforts to assist you in optimizing equipment utilization.

When you decide to work with XINBO MACHINE MAKING CO., LTD for your roofing needs you’ll not only have access to technology but also enjoy their dedication to top-notch quality and customer happiness. Their creative products and reliable support will help you stand out in delivering roofing projects customized to meet the changing needs of the industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia