Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

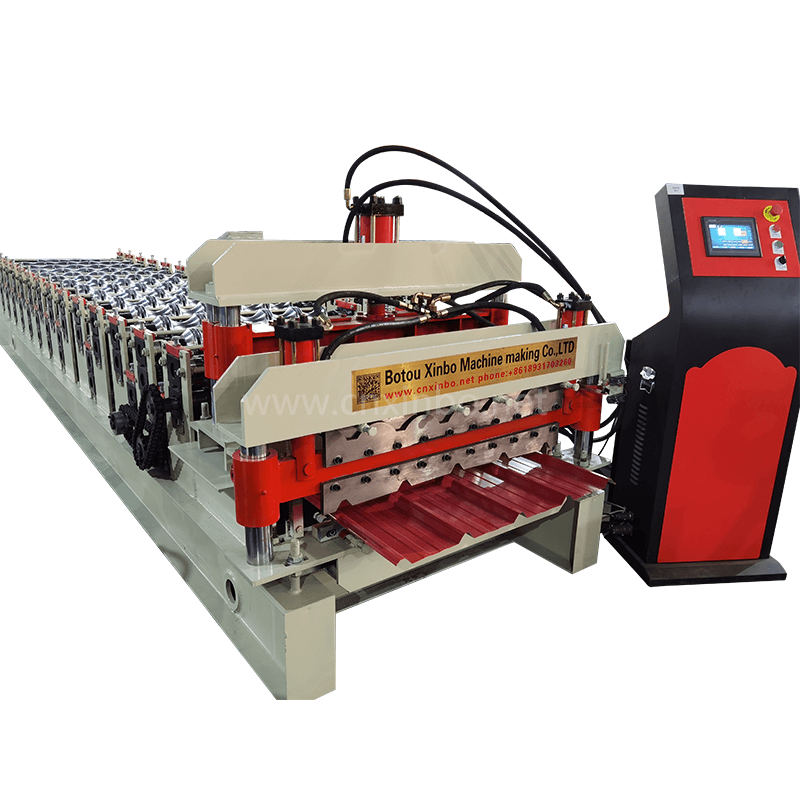

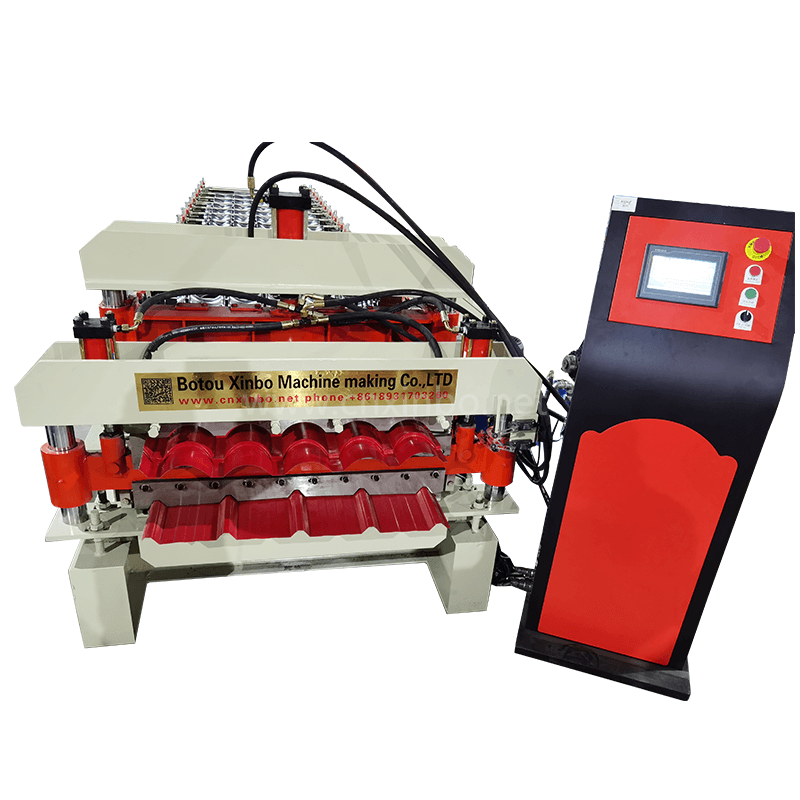

VIEW MORE→Double Layer Roofing Sheet Roll Forming Machine

Double layer roofing sheet roll forming machines are essential equipment used in the manufacturing of double-layered roof panels. These machines are designed to efficiently and accurately produce roofing sheets with two layers, providing enhanced durability and insulation for buildings.

The roll forming machine works by feeding metal coils through a series of rollers that gradually shape the material into the desired profile. The double layer roofing sheet roll forming machine is equipped with two sets of rollers, allowing for the simultaneous production of two layers of roofing sheets.

One of the key advantages of using a double layer roofing sheet roll forming machine is the ability to produce roofing panels with different profiles on each layer. This allows for greater design flexibility and customization options for architects and builders.

In addition to producing double-layered roofing sheets, these machines are also capable of producing a variety of other profiles, such as wall panels, floor decking, and ceiling panels. This versatility makes the roll forming machine a valuable asset for manufacturers in the construction industry.

Overall, the double layer roofing sheet roll forming machine is a highly efficient and reliable piece of equipment that plays a crucial role in the production of high-quality roofing materials. Its ability to produce double-layered panels with precision and speed makes it an essential investment for any manufacturer looking to enhance their product offerings and increase production efficiency.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→