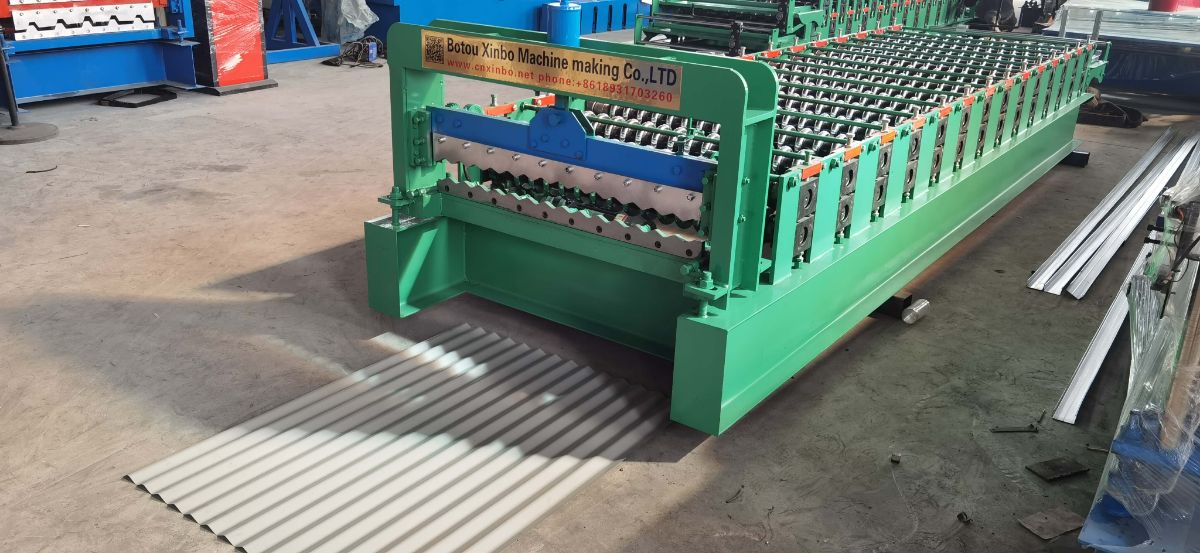

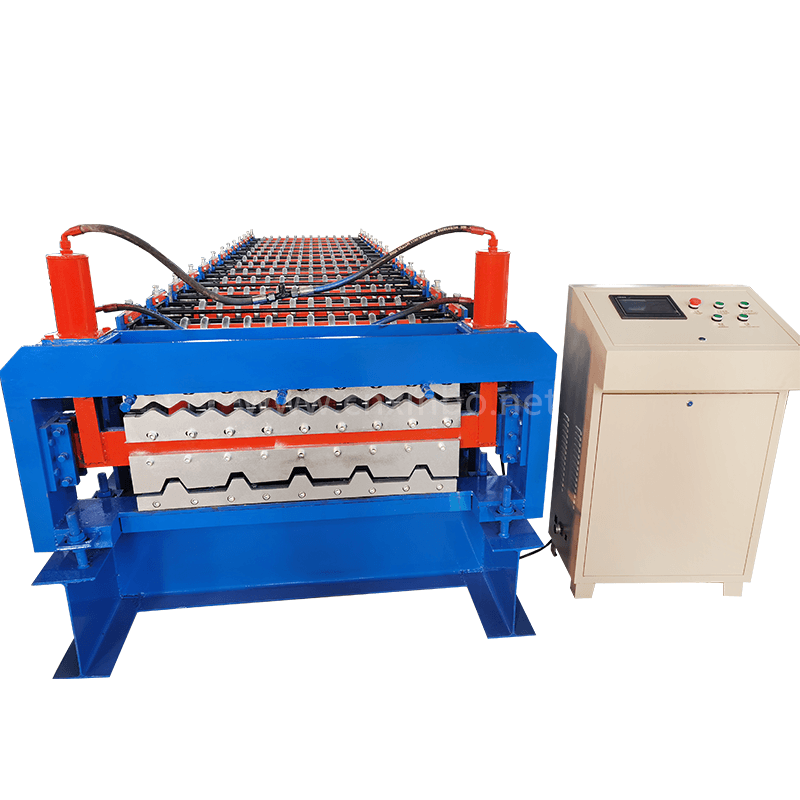

double layer roof panel machine

One of the main advantages of the double layer roll forming machine is its ability to produce two different profiles simultaneously. This feature is especially beneficial for manufacturers who require multiple profiles for their products. By producing two profiles at once, manufacturers can save time and increase production efficiency.

Additionally, the double layer roll forming machine offers great flexibility in terms of profile design. It can be easily adjusted to produce different profiles by simply changing the roller sets. This allows manufacturers to quickly adapt to changing market demands and produce a wide range of products.

Another advantage of the double layer roll forming machine is its high level of precision. The machine is equipped with advanced control systems that ensure accurate and consistent profile dimensions. This is crucial for manufacturers who require precise profiles for their products to ensure proper fit and functionality.

Furthermore, the double layer roll forming machine is highly automated, which reduces the need for manual labor and minimizes human error. This not only improves production efficiency but also enhances workplace safety.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia