Cutting-edge Application of Roll Forming Machine in the Field of Material Science

The rapid progression in material science consistently yields groundbreaking materials, which keeps elevating standards for manufacturing procedures. The roll forming machine serves as a symbol of advanced molding technology, known for superior efficacy, exactitude and plasticity. Therefore, it unveils a myriad of prospective applications within the dynamic sphere of material science.

Working Principle of Roll Forming Machine

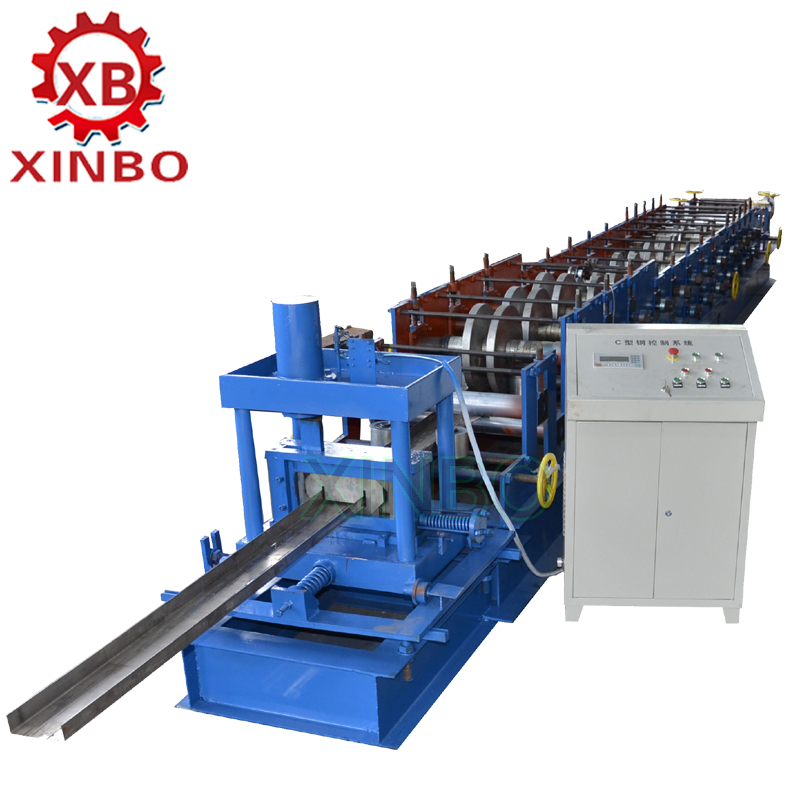

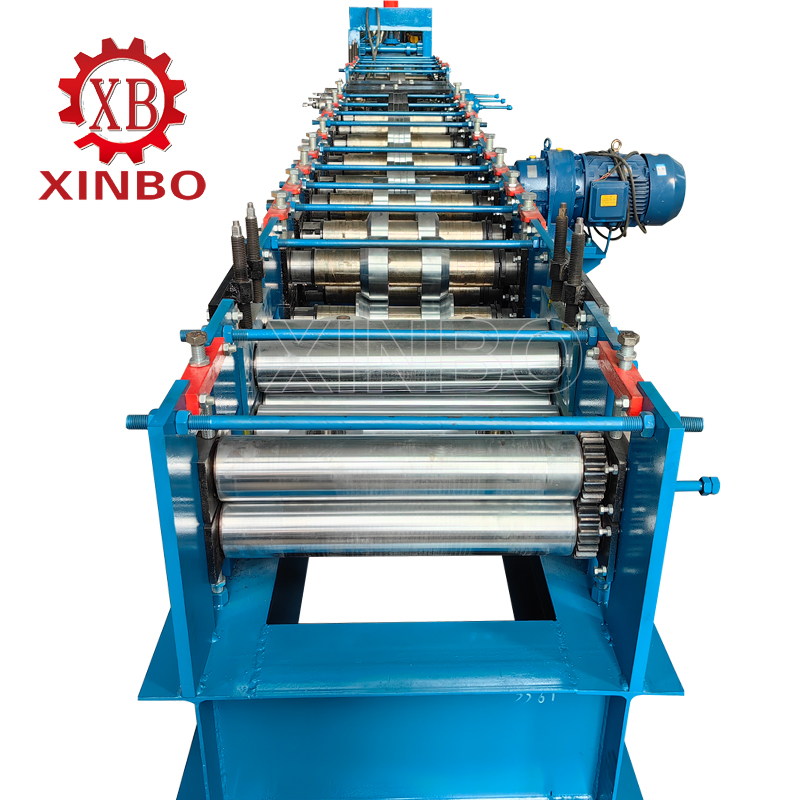

Roll Forming Machine is used to shape and mold materials by continuous rolling of materials by rollers. Its working principle is based on the principle of plastic deformation of materials, through the continuous rolling of the rollers on the material, so that the material is gradually deformed under the action of the rollers, and finally formed into the desired shape. Because of roll forming machine’s advantages of high production efficiency, low energy consumption and good product quality, it is widely used in the field of material science.

Roll Forming Machine in the field of materials science application status quo

Polymer material processing

Due to their exceptional properties, polymer materials find extensive application across a variety of domains. A fundamental element in processing these polymers is the utilized technology, with roll forming machines playing a pivotal role. The careful control of parameters and process conditions within these machines allows for meticulous molding of polymer materials, consequently enhancing product quality and performance. Roll forming machinery contributes to the fabrication of diverse products such as polymer films, tubes, plates among others – commodities that have significant usage across sectors such as packaging, construction and electronics.

Metal Material Molding

Metallic substances serve as a crucial foundation for manufacturing processes. Roll forming machines are widely used in the production of this equipment. Roll forming machines constant and proficient molding of metal substrates which significantly diminishes energy expenditure and manufacturing costs. In addition, this process can enhance the structural integrity and the properties of metallic elements. Interestingly, industries such as automotive, aviation, and shipbuilding extensively rely on roll-forming machinery for the fabrication of diverse metal components and structural constituents.

Composite Material Preparation

Composite materials have excellent comprehensive performance and are the research hotspot in the field of material science. Roll forming machine also can be seen in the preparation of composite materials. Through roll forming, it can realize the uniform distribution and close bonding of each component of composite materials and improve the performance of composite materials. At the same time, roll forming can also realize the continuous preparation of composite materials and improve production efficiency. Nowadays, roll forming machines are widely used in aerospace, sports equipment and other fields.

Integration of roll forming machine and cutting-edge technology

Digital technology

With the rapid development of digital technology, roll forming machines are gradually realizing digital control and intelligent production. Through the introduction of advanced numerical control system and sensor technology, precise control and real-time monitoring of roll forming machine can be realized to improve production efficiency and product quality. At the same time, it can also help manufacturers visualize the production process and improve the efficiency and production management.

Precision Manufacturing Technology

The precision manufacturing technology is a progressive domain within the realm of material science. The deployment of this advanced methodology in roll forming machine paves the way for amplified material processing and exceptional quality molding. Because of a refined roller design and fabrication process, roll forming machines significantly boost the precision and resilience of these rollers. Moreover, the inclusion of cutting-edge measurement and testing technologies also have token part in the advanced manufacturing procedure.

Green Manufacturing Technology

Green manufacturing is an important direction for the sustainable development of manufacturing industry. Roll forming machine also has great potential in green manufacturing. Through the use of environmentally friendly materials and energy-saving technologies, the energy consumption and emissions of roll forming machines can be reduced; through the optimization of production processes and the reduction of waste generation, the effective use of resources and recycling can be realized. These measures help to promote the greening of roll forming machines in the field of materials science.

Roll Forming Machines in the Field of Material Science

Multifunctional development direction

The application of roll forming machine in the field of material science will gradually tend to be multifunctional. Through the integration of a variety of molding processes and auxiliary functions, to achieve the effect of multi-purpose machine. For example, roll forming and other molding processes (such as cutting, punching, etc.) combined to form a complete production line; or the introduction of automated loading and unloading, quality inspection and other auxiliary functions to improve production efficiency and product quality.

High-performance materials processing capacity enhancement

With the continuous emergence of high-performance materials, roll forming machines need to have higher processing capacity and more accurate molding accuracy. In the future, roll forming machines will achieve higher efficiency and better quality in material processing.

Conclusion

In material science, the roll forming machine holds an indispensably significant role. It’s application scope continuously expanding and diversifying. The remarkable potential enhancement by merging digital technology, meticulous manufacturing procedures, and sustainable production methods has yielded unparalleled advantages in processes of material processing, preparation, and molding. As we view towards future possibilities ripple-marked with scientific progressions and market metamorphosis, it is apparent these machines will remain instrumental within the realm of material science. Acting as a catalyst for both the innovation of brand-new materials alongside strengthening traditional manufacturing sectors through considerable alterations and improvements.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia