Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→Safety and efficiency are the prime concerns in the rapidly developing construction industry. This is the reason why tough, lightweight, and high-strength steel scaffold planks are in great demand and have become an important aspect of construction safety. Advanced steel scaffold plank machines that cater to the demanding nature of modern construction projects have been at the front line in this manufacturing revolution. Therefore, businesses that are in search of something reliable can rely on XINBO MACHINE MAKING CO. LTD as a good solution with high-quality machinery according to their needs.

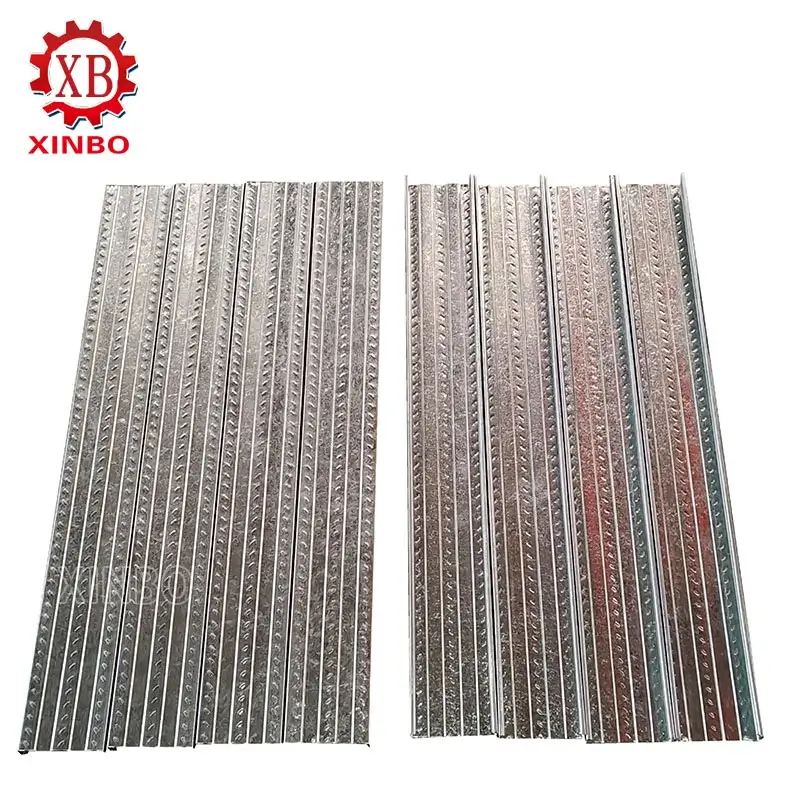

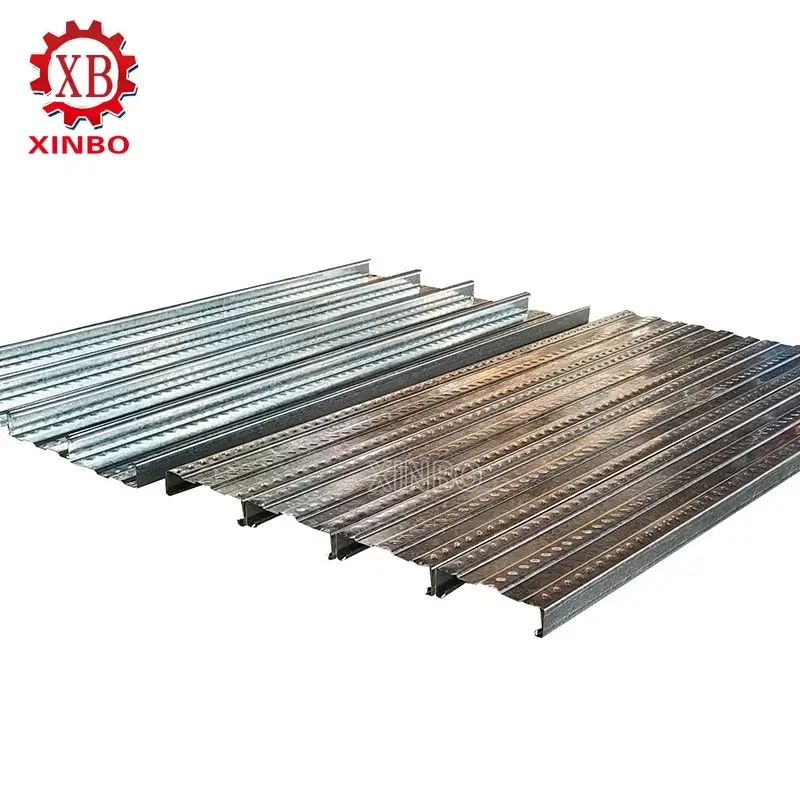

Steel scaffold planks are widely used in scaffolding systems for providing workers with safe walkways around high-level platforms. Unlike conventional wooden planks, which usually get water-absorbed and slippery during wet conditions, steel scaffold planks are designed to be lightweight, high-strength, and have minimal deposits of sediments. These features ensure increased safety, better durability, and low maintenance costs, therefore becoming highly in demand for all construction projects globally.

Various advantages have influenced the shift to steel scaffold planks from traditional ones made of wood in construction. These include the following: ·

-Enhanced Safety: Walkway Plank in Scaffolding System for Construction Safety offers superior load-bearing capacity and is less prone to defects like cracks or warping, reducing the risk of accidents.

-Fire Resistance: Unlike wooden planks, Easy-to-Install and Highly Reusable Steel Scaffold Plank is non-combustible, providing an added layer of safety in environments where fire hazards exist.

-Longevity: Galvanized Steel Planks resist corrosion and withstand harsh weather conditions, ensuring a longer service life and better return on investment.

-Anti-Slip Features: Many Scaffold Steel Step planks are designed with perforations or embossed surfaces to prevent slipping, enhancing worker safety.

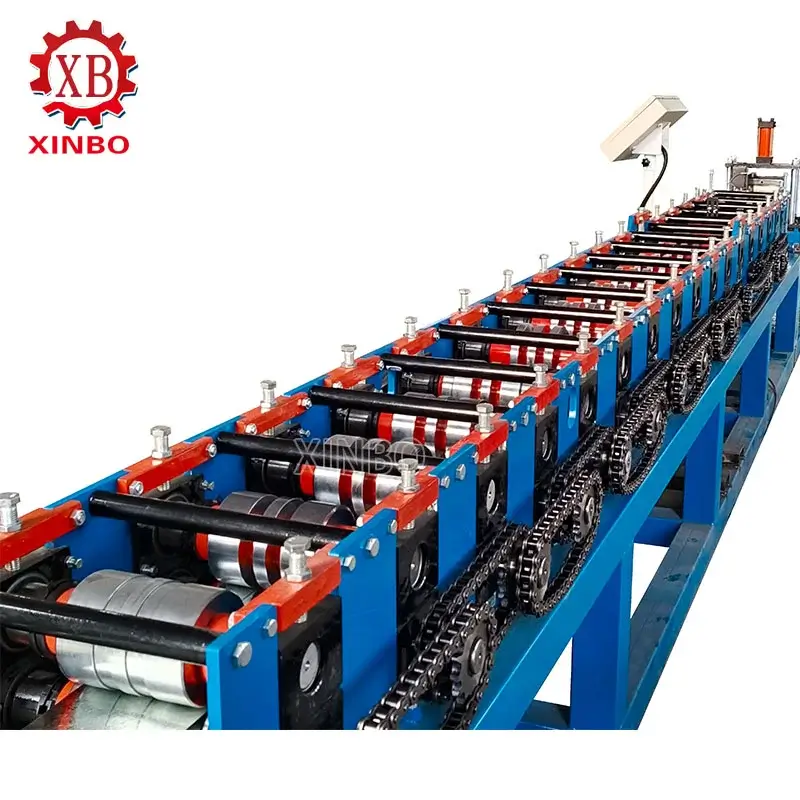

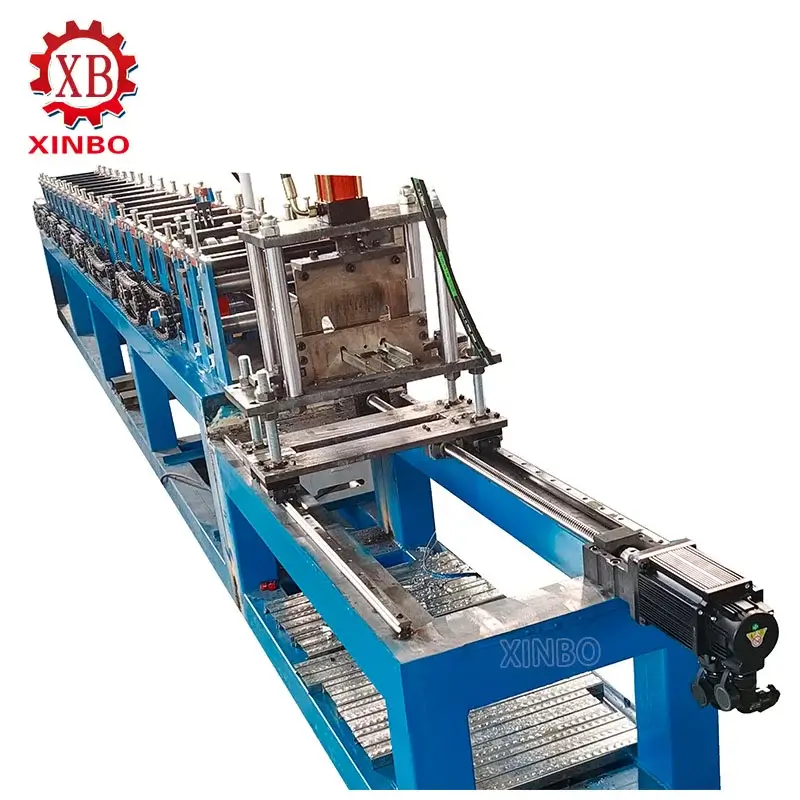

Manufacturing steel scaffold planks requires accuracy and sophistication, hence the introduction of galvanized steel scaffold plank-making machines among other specific roll-forming machines. Machines like an Iron Scaffold Board Roll Forming Machine, also known as a Perforated Wide Outer Scaffold Walkway Board Roll Forming Machine, ensure constant production of high-quality planks that meet industrial standards in terms of safety and performance.

New Scaffold Steel Step Roll Forming machines, one of which is provided by the company XINBO MACHINE MAKING CO. LTD, facilitate the whole process of manufacture by allowing customized designs, increased efficiency, and lowered production costs.

The advanced walkway plank in scaffolding system for construction safety making machine has a number of features that help to enhance efficiency and increase quality in the planks produced:

High Precision: Advanced rollers and cutting systems ensure each plank produced on these Fitting Part of Construction Scaffolds Making Machines conforms to exact specifications. This is so important in terms of scaffolding structures for reasons relating to safety and dependability. · Durable: Fabricated with heavy-duty materials, these Steel Decking Roll Forming Machines will resist continuous use, hence reducing downtime and saving maintenance costs.

Versatility: Capable of producing various designs and sizes of planks, they cater to diverse construction needs, from lightweight yet high-strength planks to anti-sediment designs.

Automation: Incorporating automated systems enhances productivity and minimizes human error, leading to consistent product quality.

When choosing a steel scaffold plank machine, consider the following factors:

– Production Capacity:Assess your project’s scale to determine the required output speed and volume.

–Customization Options:See that the machine is able to produce planks according to your design and size requirements.

-Quality Assurance:Seek machines that offer consistent precision to maintain high safety standards in your scaffolding systems.

-Supplier Reputation:Partner with reputable manufacturers that provide reliable machinery and after-sales support.

XINBO MACHINE MAKING CO. LTD was established in 2014 and, since then, has gained a reputation for innovative and reliable roll-forming machines to meet clients’ specific needs worldwide.

Technical Specifications of XINBO Scaffold Steel Step Roll Forming Machines

The following are some of the features of the XINBO Pedal Panel Roll Forming Machine that speaks to quality and innovation:

-Processing Material: GI coils

-Input Width: Customized

-Formed Width: As needed

-Processing Thickness: Standard: max 1.0mm

-Frame Style: Square pipe welded frame

-Material of Rollers: 45# steel, with heat treatment and hard chromed

-Diameter of Shaft: 50mm

-Production Speed: Standard: 0–15m/min; customized

-Roller Driven: Chain Transmission

-Cutting Model: Hydraulic Profile Cutting

-Length Measurement: Encoder

-Control Style: PLC

-Operation Model: Button + Touch Screen

-Total Power: 4+3KW; customized

-Voltage: 380V, 50Hz, 3 phases; or at buyer’s request

XINBO’s machines are optimized for export, designed to fit into standard 40ft HQ containers, thereby reducing logistics costs for international clients. Due to the skills of its team and strict adherence to quality standards, XINBO has made sure that its machines will be able to respond properly to the very demanding markets of Europe, the UK, and Canada.

The trend the world construction industry is taking is toward sustainable and safer scaffoldings, and steel scaffold planks emerge exactly in line with the demand. With the rise in the usage of prefabricated construction methods, the requirement for lightweight, reusable, and strong scaffold planks is expected to increase.

Besides, the development of the technology of roll-forming has reached such a point that hydraulic profile cutting and encoder-based length measurement systems set a new standard for efficiency and precision. At the leading edge of such innovations are manufacturers like XINBO MACHINE MAKING CO. LTD, offering solutions that meet or even exceed the expectations of the industry.

In the changing nature and magnitude of the construction business, safety always comes first. The demand for quality steel scaffolding planks, affording employees working at heights with a safe and solid platform, cannot be overemphasized. These much-needed components rely on special machines designed to produce pieces with accuracy and durability.

When it comes to reliable solutions for building construction steel scaffold planks machines, XINBO MACHINE MAKING CO. LTD is a name to trust. Equipped with state-of-the-art machinery, such as the Pedal Panel Roll Forming Machine, it ensures safety, efficiency, and sustainability in all construction projects.

With top-of-the-line galvanized steel scaffold plank making machines, companies can invest in bettering their production, reducing overall costs, and helping to make construction safer across the globe. Contact XINBO today to find out the best innovative solutions and take a step toward revolutionizing your manufacturing processes.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→